Gamma-amino butyric acid-containing fermentation milk and manufacturing method thereof

The technology of aminobutyric acid and production method is applied in the field of fermented milk containing γ-aminobutyric acid and its production, which can solve the problems of inability to apply food, low output and high cost, and achieve good taste, texture and safety High, functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Fresh milk (Bright Dairy Co., Ltd.): protein 3.0%, fat 3.1%.

[0044] Heat fresh milk to 40-50°C, mix with 1% sodium glutamate, stir for 15 minutes; preheat to 60-65°C, homogenize at 17MPa; sterilize at 90-95°C for 30 minutes; cool to 32°C, inoculate Han Mori company's strain ABT-5, the strain consists of Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacterium lactis BB-12, a total of 10 6 cfu / mL, the yield of γ-aminobutyric acid is 0.3% when it is incubated for 72 hours, and the percentage is the mass percent of γ-aminobutyric acid in the total amount of fermented milk.

Embodiment 2

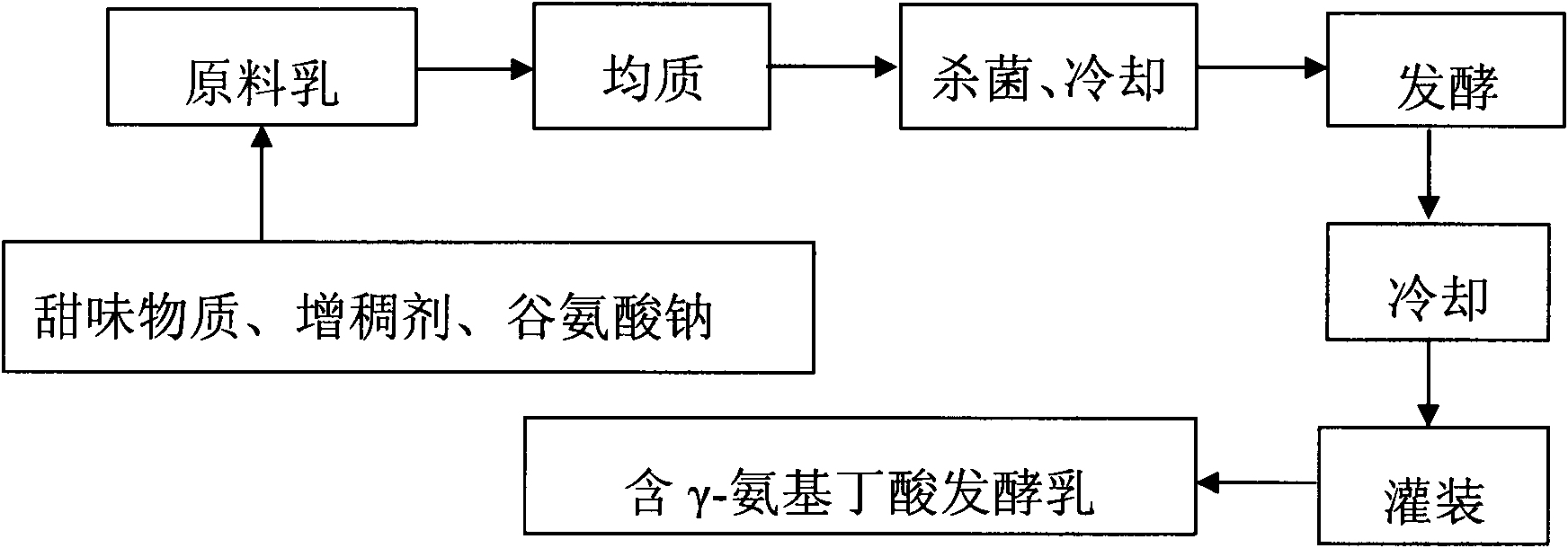

[0046] The schematic diagram of the technological process of this embodiment is as figure 1 shown.

[0047] Fresh skim milk (Bright Dairy Co., Ltd.), heat fresh skim milk to 40-50°C, mix with 7% fructose syrup, 0.1% pectin, 0.2% modified starch, 0.3% gelatin and 1% sodium glutamate Mix and stir for 20 minutes; preheat to 55-60°C, homogenize at 20MPa; sterilize at 137°C for 5 seconds; cool to 32°C, inoculate γ-aminobutyric acid-producing strain Danisco strain Yo-mix 883 for a total of 10 6 The cfu / mL is composed of Lactobacillus delbrueckii subsp.bulgaricus and Streptococcus thermophilus. After incubation for 72 hours, the yield of GABA is 0.4%. The percentage is GABA Accounting for the mass percentage of the total amount of fermented milk.

Embodiment 3

[0049] Fresh milk (Bright Dairy Co., Ltd.): protein 3.0%, fat 3.1%.

[0050] Heat fresh milk to 40-50°C, mix it with 7% fructose syrup and 1% sodium glutamate, and stir for 18 minutes; preheat to 60-65°C, homogenize at 25 MPa; sterilize at 137°C for 5 seconds; cool to 32 ℃, inoculate Danisco strain choozit Lh100, which consists of Lactobacillus bulgaricus and Lactobacillus helveticus, with a total inoculum of 10 6 cfu / mL, heat-preserved fermentation for 72 hours, the yield of γ-aminobutyric acid is 0.6%, and the percentage is the mass percentage of γ-aminobutyric acid in the total amount of fermented milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com