Novel desulfurization-denitrification integrated device

A denitrification and desulfurization chamber technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as easy breakage, waste of resources, and expensive catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

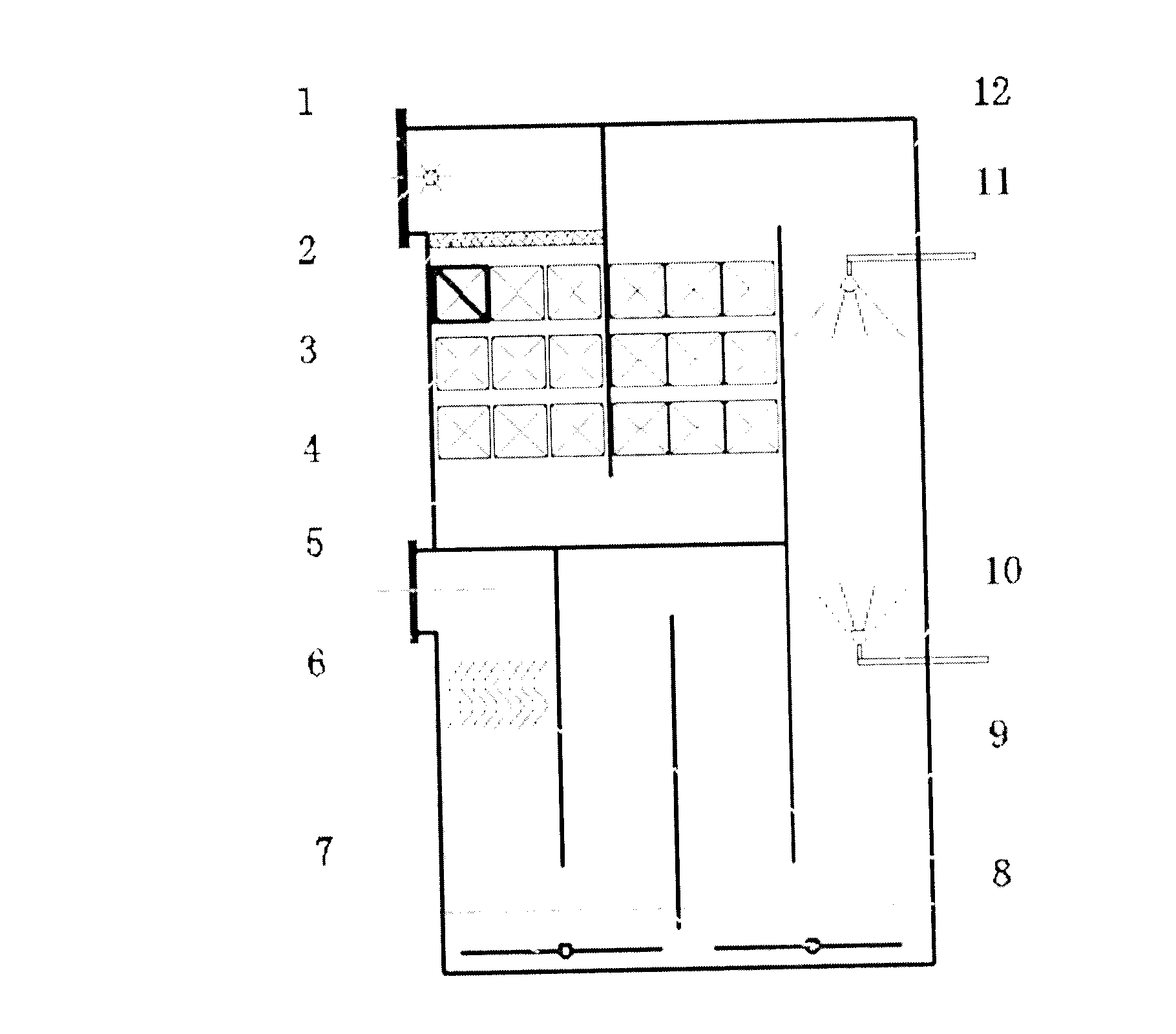

[0008] See attached figure 1 , the present invention includes: flue gas inlet 1, ammonia wind mixing spray gun 2, uniform flow splitter 3, catalyst module 4, denitrification chamber 5, flue gas outlet 6, follicle generator 7, demister 8, follicle desulfurization chamber 9. The secondary humidification nozzle 10, the primary humidification nozzle 11, and the tower body 12.

[0009] The flue gas enters the tower body 12 through the flue gas inlet 1, mixes with the ammonia gas injected by the ammonia-wind mixing spray gun 2, and is evenly dispersed in the denitration chamber 5 by the uniform distributor 3, and fully contacts with the catalyst module 4. The catalyst module is Attapulgite is used as the denitration catalyst carrier, and metal oxides such as vanadium oxide and tungsten oxide are used as catalysts. The nitrogen oxides in the flue gas undergo a catalytic reduction reaction with ammonia under the action of the catalyst, and the nitrogen oxides are reduced to nitrogen. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com