Longhole double-spiral inner-cooling drill bit

A double-helix and drill bit technology, which is applied in drilling/drilling equipment, drill repair, twist drill, etc., can solve the problem that precision deep holes cannot meet precision machining requirements, poor straightness of titanium alloy deep holes, and adhesion between titanium alloy and tools. to improve the ability of anti-adhesive wear, reduce cutting resistance, and reduce the effect of adhesive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

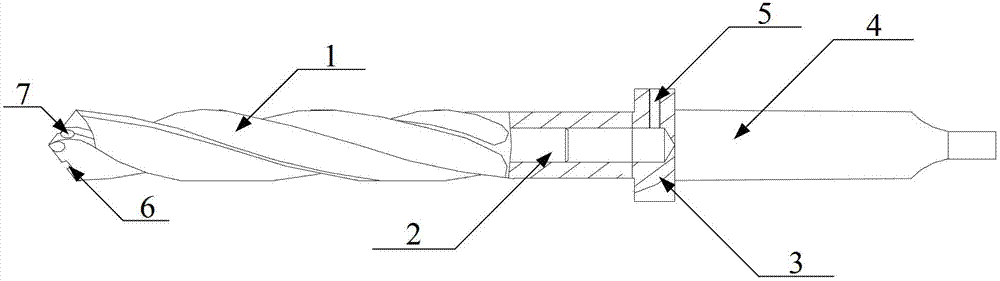

[0033] Such as figure 1 , 2 As shown, the deep-hole double-helix internal cooling drill bit includes a drill bit, and the tail end of the drill bit is also connected with a drill shank, and the drill shank is integrated with the drill bit by welding.

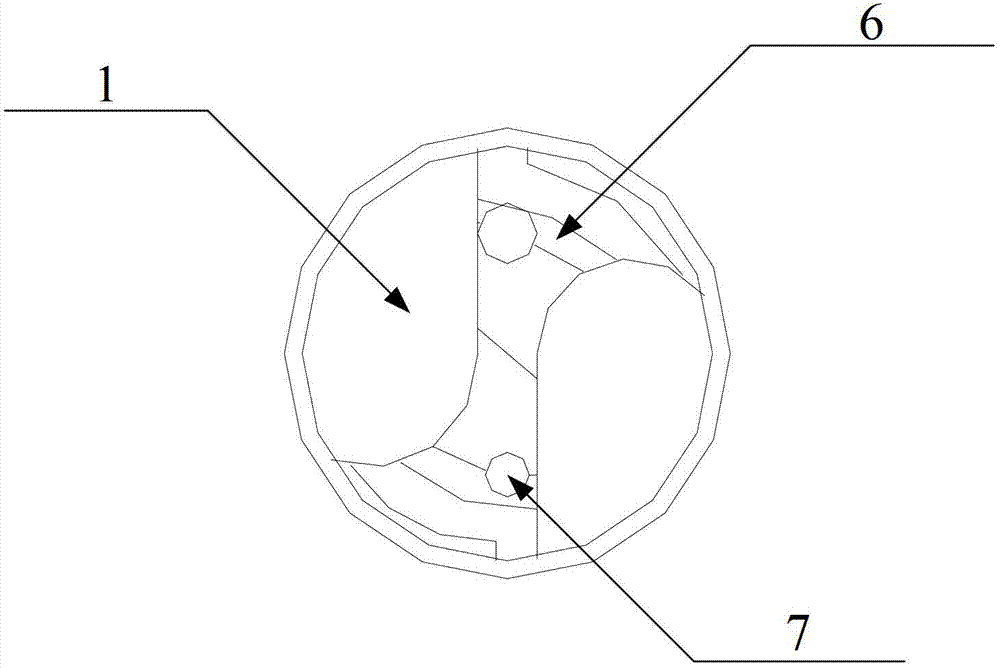

[0034] The above-mentioned drill bit includes a drill bit body 1, a connector 2 is also arranged at the rear end of the drill bit body 1, and an internal cooling screw hole 7 is also arranged inside the drill bit body 1 and the connector 2, and at the same time, on the drill bit body 1 A chip splitter 6 and an internal cooling screw hole 7 are provided.

[0035] Preferably, the apex angle of the drill body 1 is 140°.

[0036] Preferably, the number of the chip splitting flutes 6 is two, which are symmetrically arranged on the cutting edge of the front end of the drill body 1 .

[0037] Preferably, the number of the internal cooling screw holes 7 is two, which are symmetrically arranged on the cutting edge of the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com