Aluminum-doped zinc oxide electric conduction powder and preparation method thereof

An aluminum-doped zinc oxide, conductive powder technology, used in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

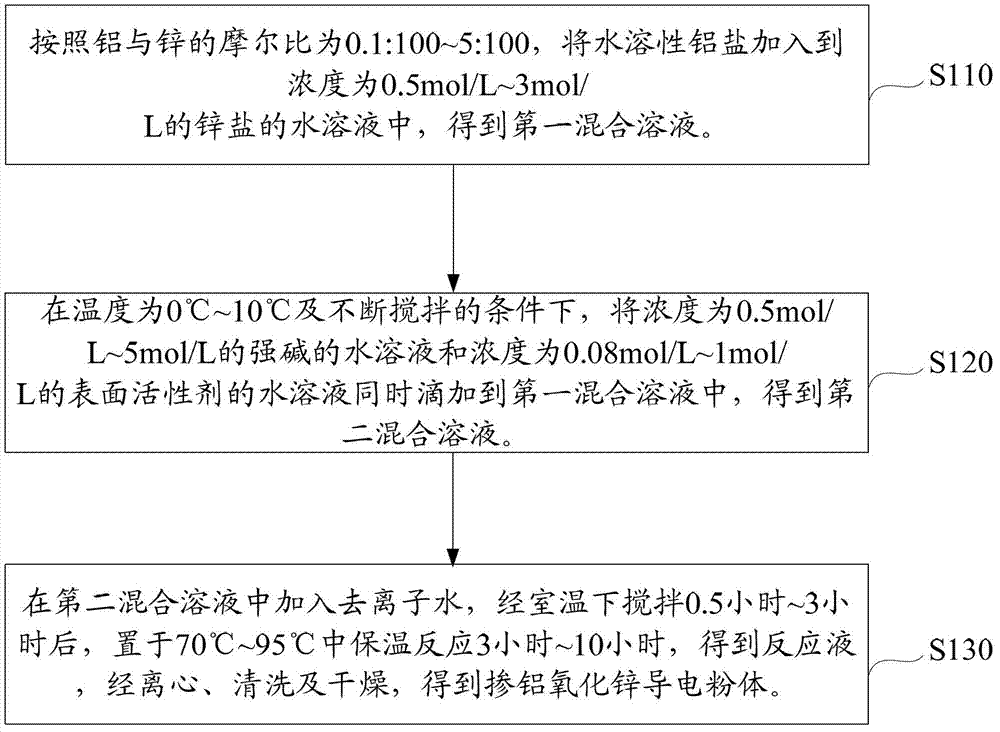

[0028] Such as figure 1 Shown, the preparation method of the aluminum-doped zinc oxide conductive powder of one embodiment, comprises the steps:

[0029] Step S110: according to the molar ratio of aluminum to zinc being 0.1:100-5:100, adding water-soluble aluminum salt to the aqueous solution of zinc salt with a concentration of 0.5 mol / L-3 mol / L to obtain a first mixed solution.

[0030] The aqueous solution of zinc salt with a concentration of 0.5mol / L~3mol / L is beneficial to the nucleation and growth of the product. If the concentration is too high, the growth rate of the product will be too fast, which is not conducive to the control of the morphology of the product.

[0031] The zinc salt may be a zinc salt commonly used in the art, preferably zinc nitrate, zinc chloride or zinc sulfate.

[0032] The water-soluble aluminum salt may be a water-soluble aluminum salt commonly used in the art, preferably aluminum nitrate nonahydrate or aluminum sulfate.

[0033] Step S120: ...

Embodiment 1

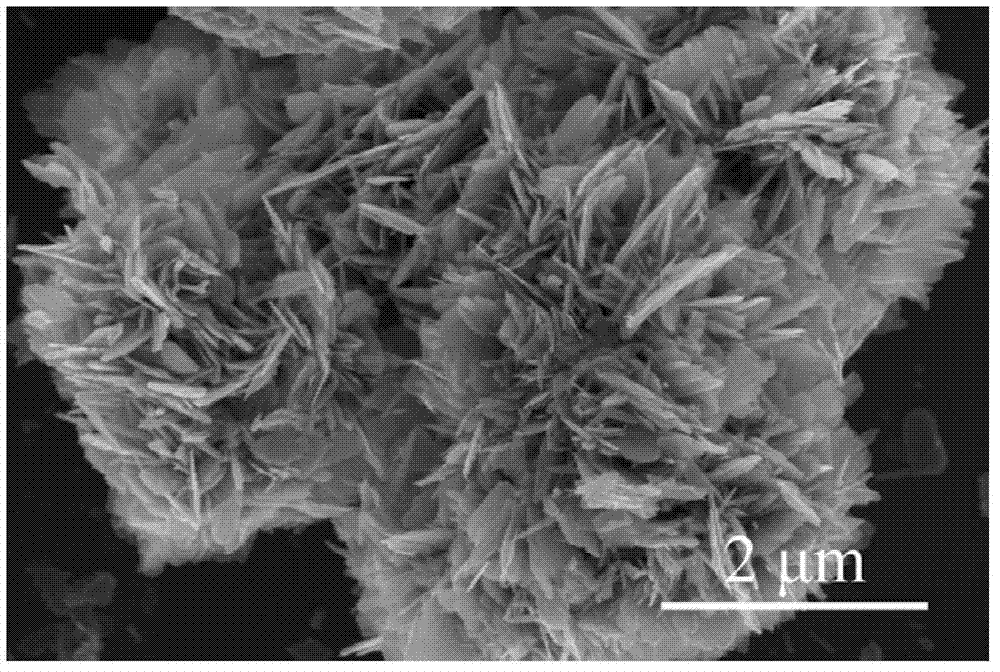

[0049] The preparation steps of the aluminum-doped zinc oxide conductive powder of the present embodiment are as follows:

[0050] (1) According to the molar ratio of aluminum to zinc of 0.4:100, add 0.03752g of aluminum nitrate nonahydrate to the aqueous solution of zinc nitrate with a concentration of 1mol / L to prepare 25ml of the first mixed solution.

[0051] (2) At a temperature of 0°C and under constant stirring, mix 35 ml of an aqueous solution of sodium hydroxide with a concentration of 3 mol / L and 3 ml of sodium dodecylbenzenesulfonate with a concentration of 0.1 mol / L The aqueous solution is simultaneously added dropwise to the first mixed solution to obtain a second mixed solution.

[0052] (3) Add 37 ml of deionized water to the second mixed solution, after stirring gently at room temperature for 1.5 hours, put it in an incubator and place it at 75°C for 8 hours to keep the reaction for 8 hours to obtain the reaction solution, centrifuge the reaction solution, and ...

Embodiment 2

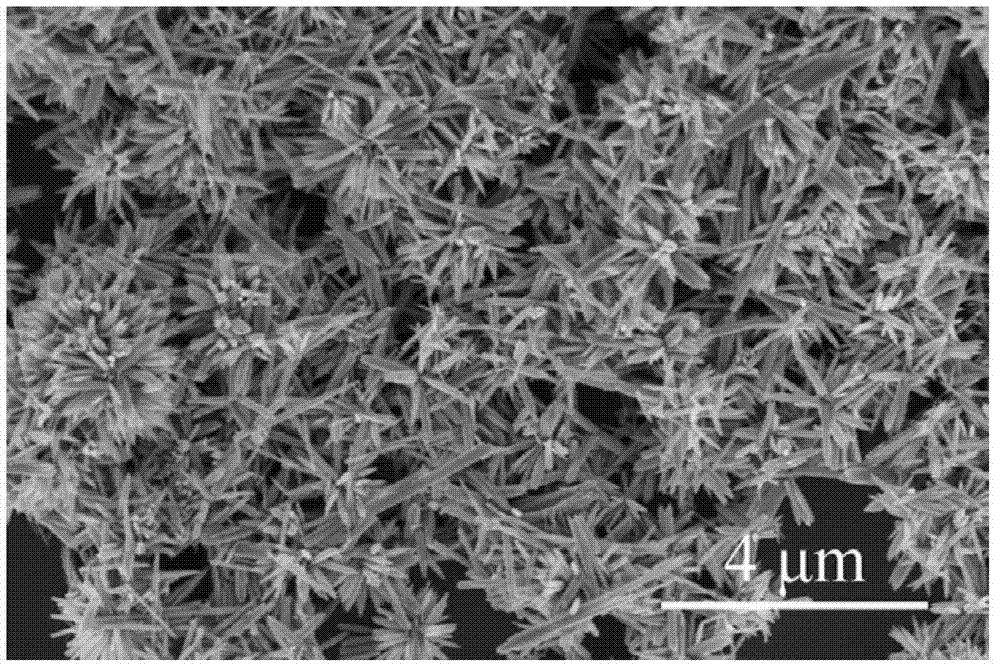

[0054] The preparation steps of the aluminum-doped zinc oxide conductive powder of the present embodiment are as follows:

[0055] (1) According to the molar ratio of aluminum to zinc of 1:100, add 0.0938g of aluminum nitrate nonahydrate to the aqueous solution of zinc nitrate with a concentration of 1mol / L to prepare 25ml of the first mixed solution.

[0056] (2) At a temperature of 0°C and under constant stirring, mix 35 ml of an aqueous solution of sodium hydroxide with a concentration of 3 mol / L and 3 ml of sodium dodecylbenzenesulfonate with a concentration of 0.1 mol / L The aqueous solution is simultaneously added dropwise to the first mixed solution to obtain a second mixed solution.

[0057] (3) Add 37 ml of deionized water to the second mixed solution, after stirring gently at room temperature for 1.5 hours, put it in an incubator and place it at 75°C for 8 hours to keep the reaction for 8 hours to obtain the reaction solution, centrifuge the reaction solution, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com