Method of preparing malonate diester by using malic acid as raw material

A technology of malonate diester and malic acid, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of no synthesis of malonate diester, etc., and achieve an efficient reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

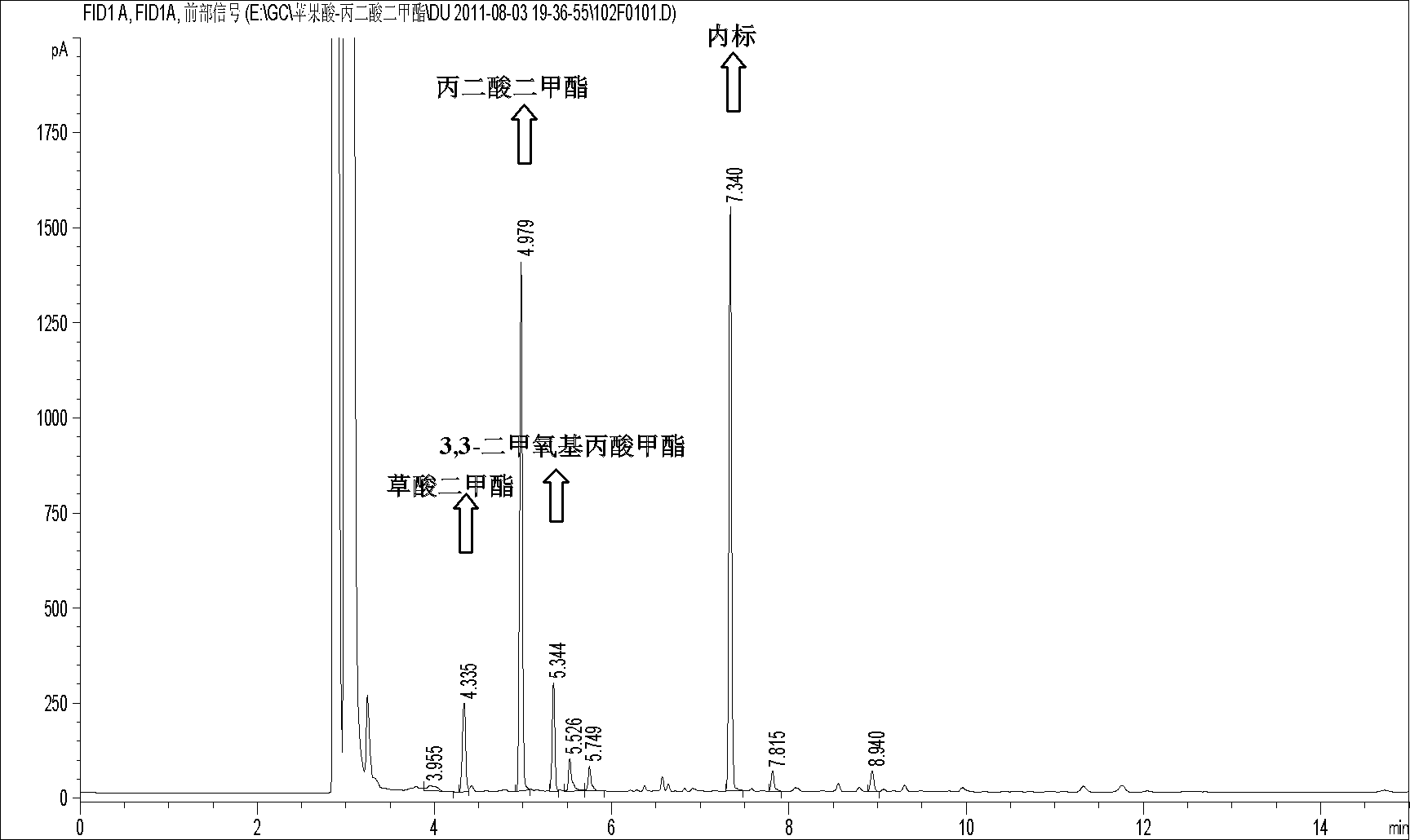

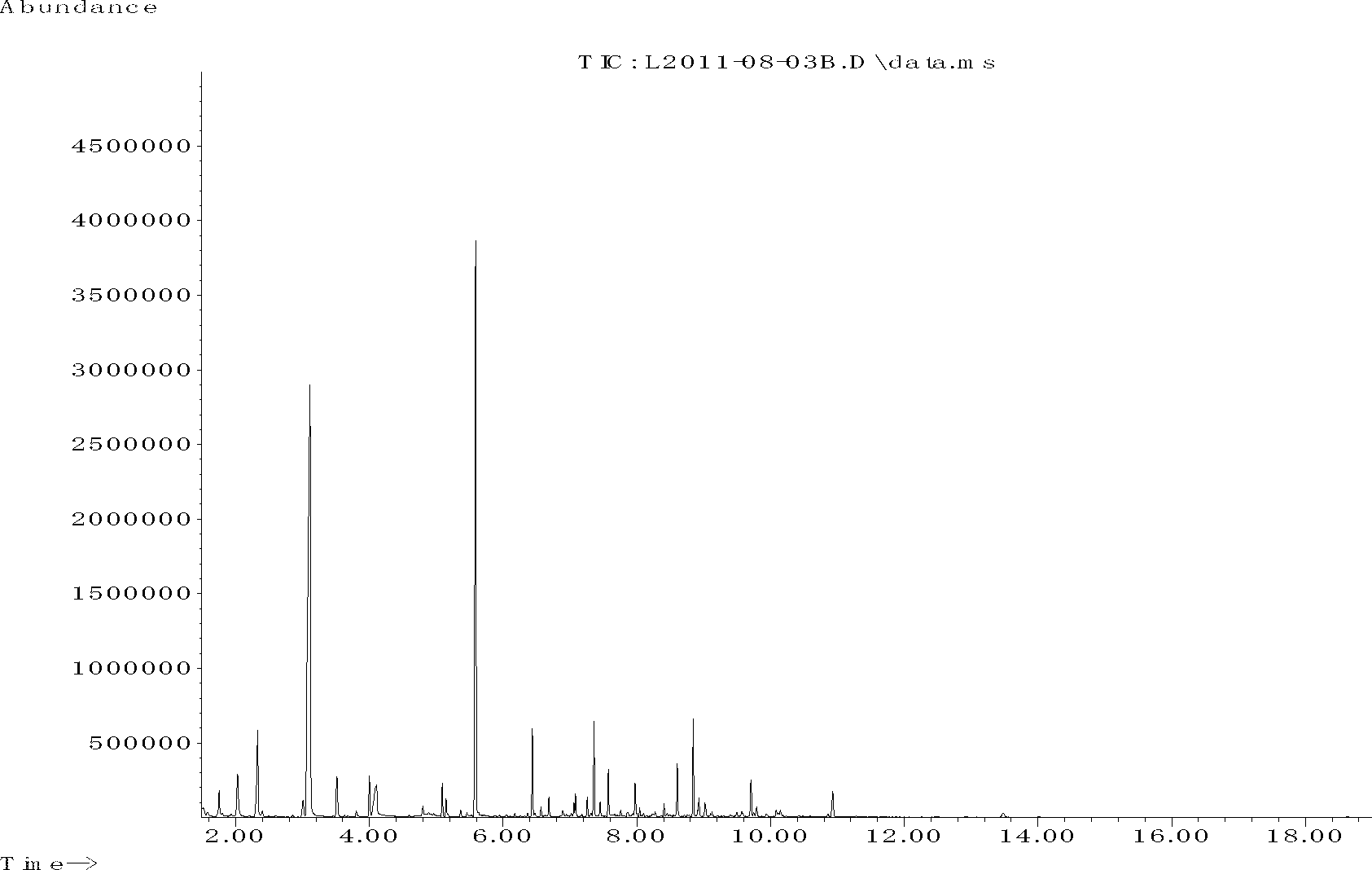

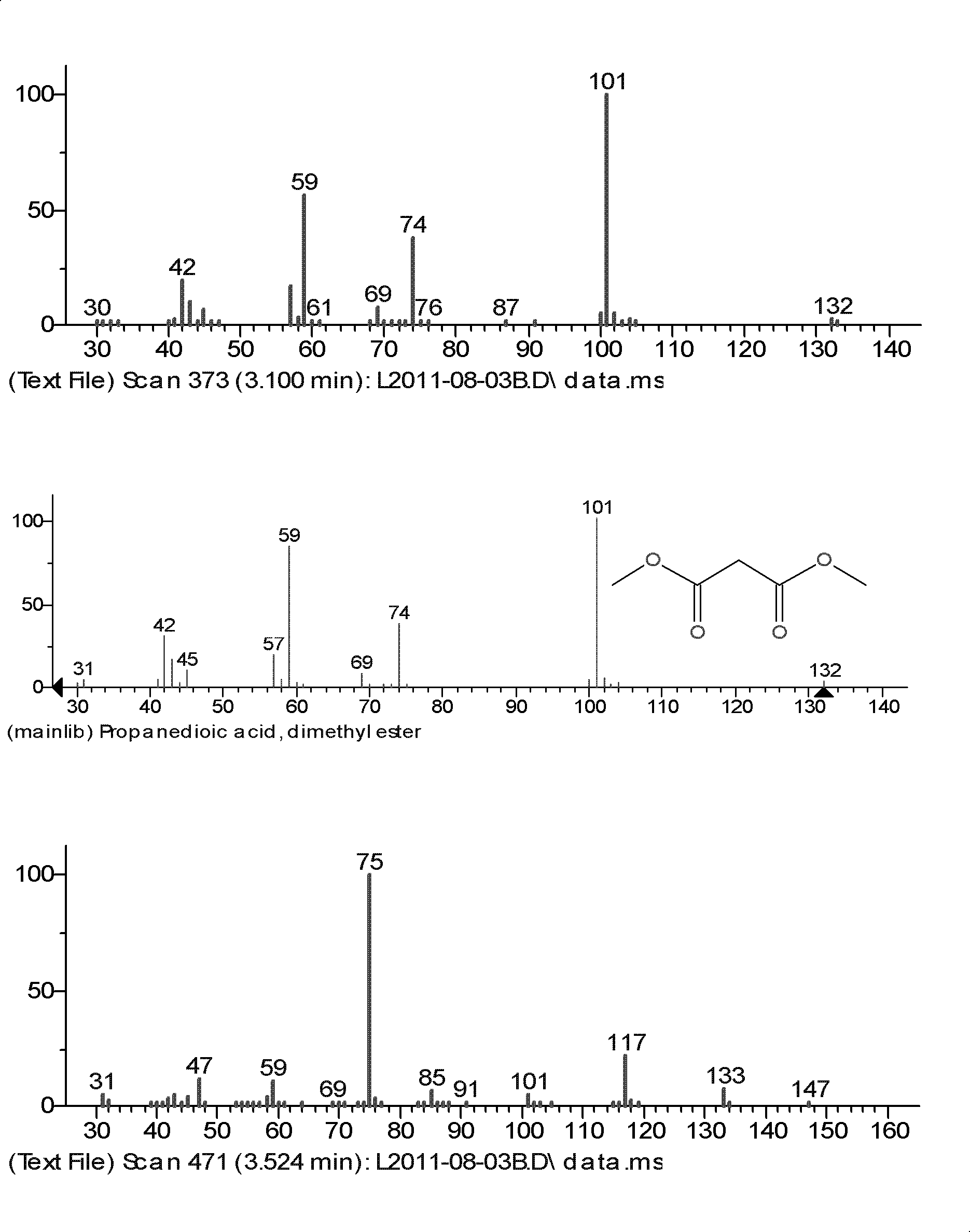

[0016] Embodiment 1: With 0.3350g malic acid, 1mol% (relative to raw material malic acid) phosphomolybdovanadium heteropolyacid, join in the 35mL reactor, add 3mL methanol, close the kettle, fill in the oxygen pressure and be 1.0MPa, under stirring Raise the temperature to 90°C and keep it for 6h. It was then cooled to room temperature and carefully depressurized to atmospheric pressure. All the products were transferred to the volumetric flask, after adding the internal standard naphthalene, the volume was constant with acetonitrile, and then the samples were analyzed by gas chromatography (GC, figure 1 ), internal standard quantitative method obtains the selectivity of malonate diester in the product. According to the calculation of formula malonate diester selectivity=(mass amount of malonate diester) / (sum of the amount of all product substances after the reaction), the selectivity of malonate diester is 59.6%. Use GC-MS and gas chromatographic retention time of standard ...

Embodiment 2

[0017] Embodiment 2: With 0.3350g malic acid, 1mol% (relative to raw material malic acid) vanadyl sulfate, join in the 35mL reactor, add 3mL methanol, close the kettle, fill in oxygen pressure and be 1.0MPa, be heated up to 100 under stirring ℃, and keep for 6h. It was then cooled to room temperature and carefully depressurized to atmospheric pressure. The product was analyzed according to the method in Example 1, and the selectivity of malonate diester was 76.1%.

Embodiment 3

[0018] Embodiment 3: With 0.3350g malic acid, 1mol% (relative to raw material malic acid) vanadyl acetylacetonate, join in the 35mL reactor, add 3mL methanol, close the kettle, fill in oxygen pressure and be 1.0MPa, be heated up to under stirring 100°C and keep for 4h. It was then cooled to room temperature and carefully depressurized to atmospheric pressure. The product was analyzed according to the method in Example 1, and the selectivity of malonate diester was 70.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com