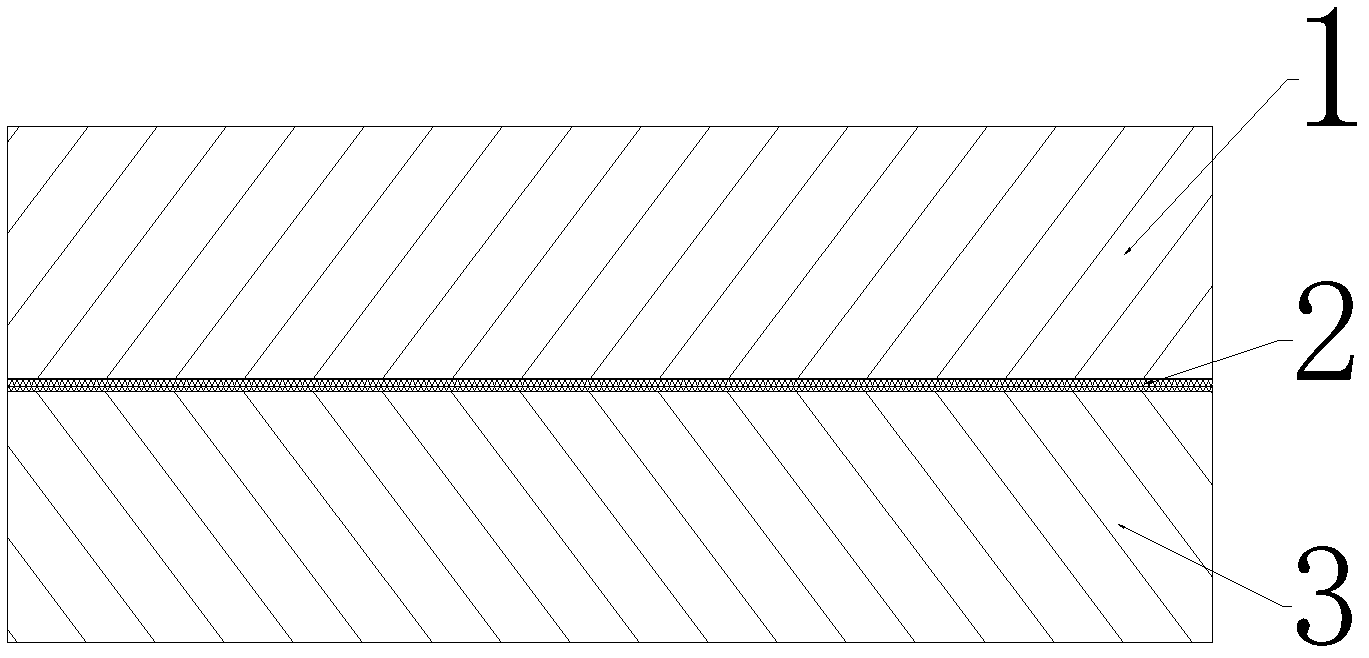

Copper plastic composite strap suitable for telecommunication cable and optical cable and preparation method of copper plastic composite strap

A copper-plastic composite tape and communication cable technology, which is applied in communication cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems that polyethylene and ethylene copolymers cannot fully meet the actual needs, and achieve the improvement of cooling liquid cooling process, Conducive to thinning and saving copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

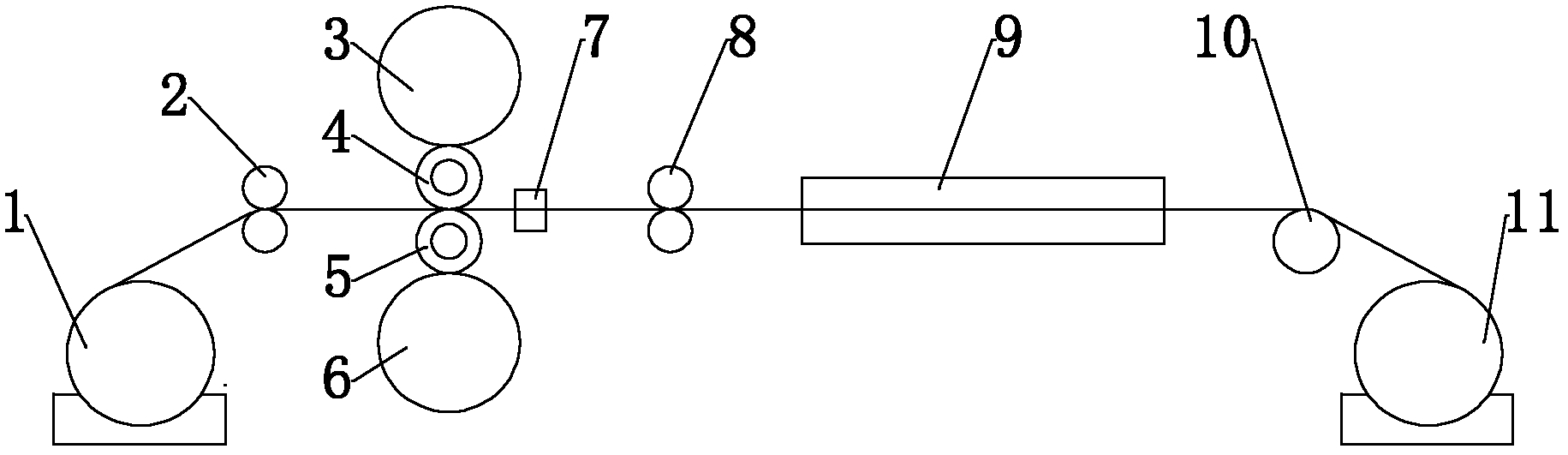

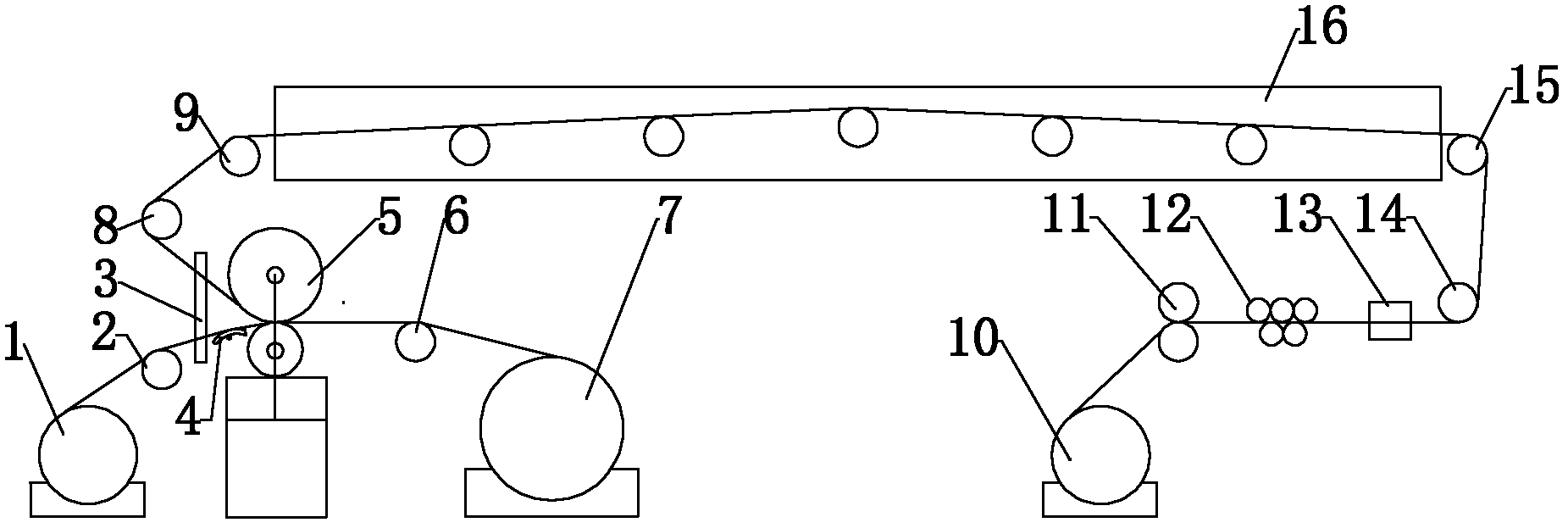

[0078] Production process of ultra-thin copper layer:

[0079] Pre-finished product rolling: select T2 copper strip with a thickness of 0.12mm, and roll it to a pre-finished product with a thickness of 0.08mm at a rolling speed of 0.8m / s.

[0080] Softening: The pre-finished product is softened by continuous online annealing, the softening temperature is 680°C, and the softening speed is 15m / min.

[0081] Finished product rolling: The pre-finished product is rolled to a finished product with a thickness of 0.03mm by a small four-high rolling mill with a diameter of 60mm working roll and a diameter of 300mm supporting roll. The work roll adopts hollow water-cooled roll, and the work roll directly cools the copper strip and adds an air cooling system at the discharge end for enhanced cooling, and at the same time blows the copper strip to keep the surface of the copper strip free of impurities and clean.

[0082] Softening: The finished copper strip after rolling is softened by...

Embodiment 2

[0108] Production process of ultra-thin copper layer:

[0109] Pre-finished product rolling: select T2 copper strip with a thickness of 0.12mm, and roll it to a pre-finished product with a thickness of 0.06mm at a rolling speed of 1.0m / s.

[0110] Softening: The pre-finished product is softened by continuous online annealing, the softening temperature is 750°C, and the softening speed is 20m / min.

[0111] Finished product rolling: the pre-finished product is rolled to a finished product with a thickness of 0.03mm by a small four-high rolling mill with a diameter of 90mm working roll and a diameter of 300mm supporting roll. The work roll adopts hollow water-cooled roll, and the work roll directly cools the copper strip and adds an air cooling system at the discharge end for enhanced cooling, and at the same time blows the copper strip to keep the surface of the copper strip free of impurities and clean.

[0112] 4) Softening: the finished copper strip after rolling is softened...

Embodiment 3

[0136] Production process of ultra-thin copper layer:

[0137] Pre-finished product rolling: select T2 copper strip with a thickness of 0.10mm, and roll it to a pre-finished product with a thickness of 0.06mm at a rolling speed of 1.5m / s.

[0138] Softening: The pre-finished product is softened by continuous online annealing, the softening temperature is 800°C, and the softening speed is 25m / min.

[0139] Finished product rolling: the pre-finished product is rolled to a finished product with a thickness of 0.02mm by a small four-high rolling mill with a diameter of 90mm working roll and a diameter of 280mm supporting roll. The work roll adopts hollow water-cooled roll, and the work roll directly cools the copper strip and adds an air cooling system at the discharge end for enhanced cooling, and at the same time blows the copper strip to keep the surface of the copper strip free of impurities and clean.

[0140] Softening: The finished copper strip after rolling enters the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com