Post-processing method of porous gas diffusion layer for fuel cell

A technology of a gas diffusion layer and a processing method, which is applied in the post-processing field of a porous gas diffusion layer, can solve the problems such as the difficulty in grasping the ratio of large pores and small pores, the cumbersome preparation method of the porous gas diffusion layer, and the difficulty in controlling the pore size, so as to reduce the size of the pores. Aperture range, flatness increase, effect of surface flatness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] 1)-4) four steps are the same as comparative example;

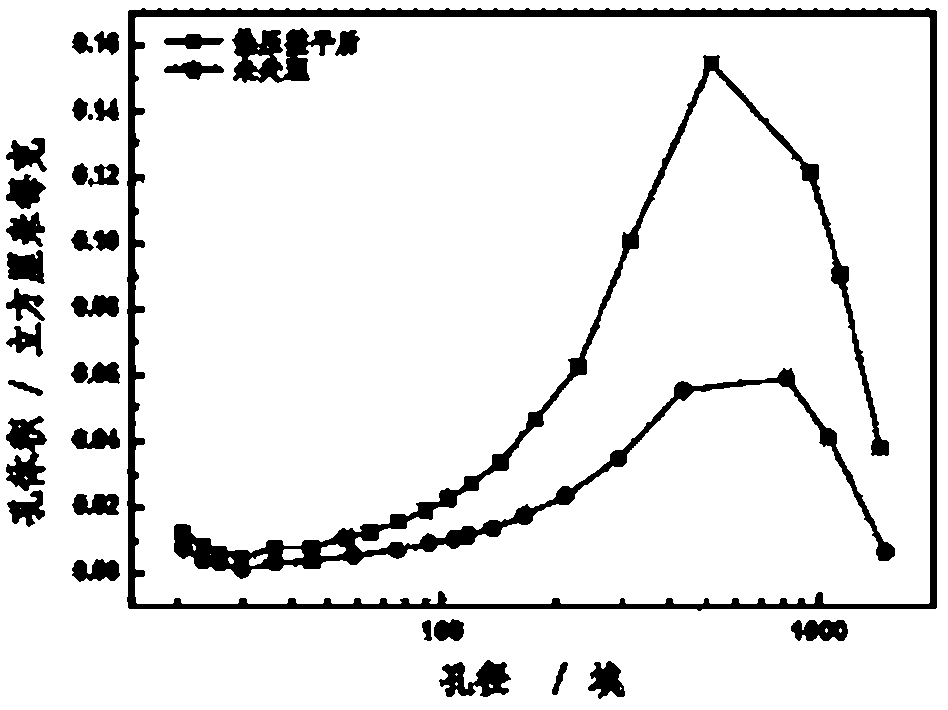

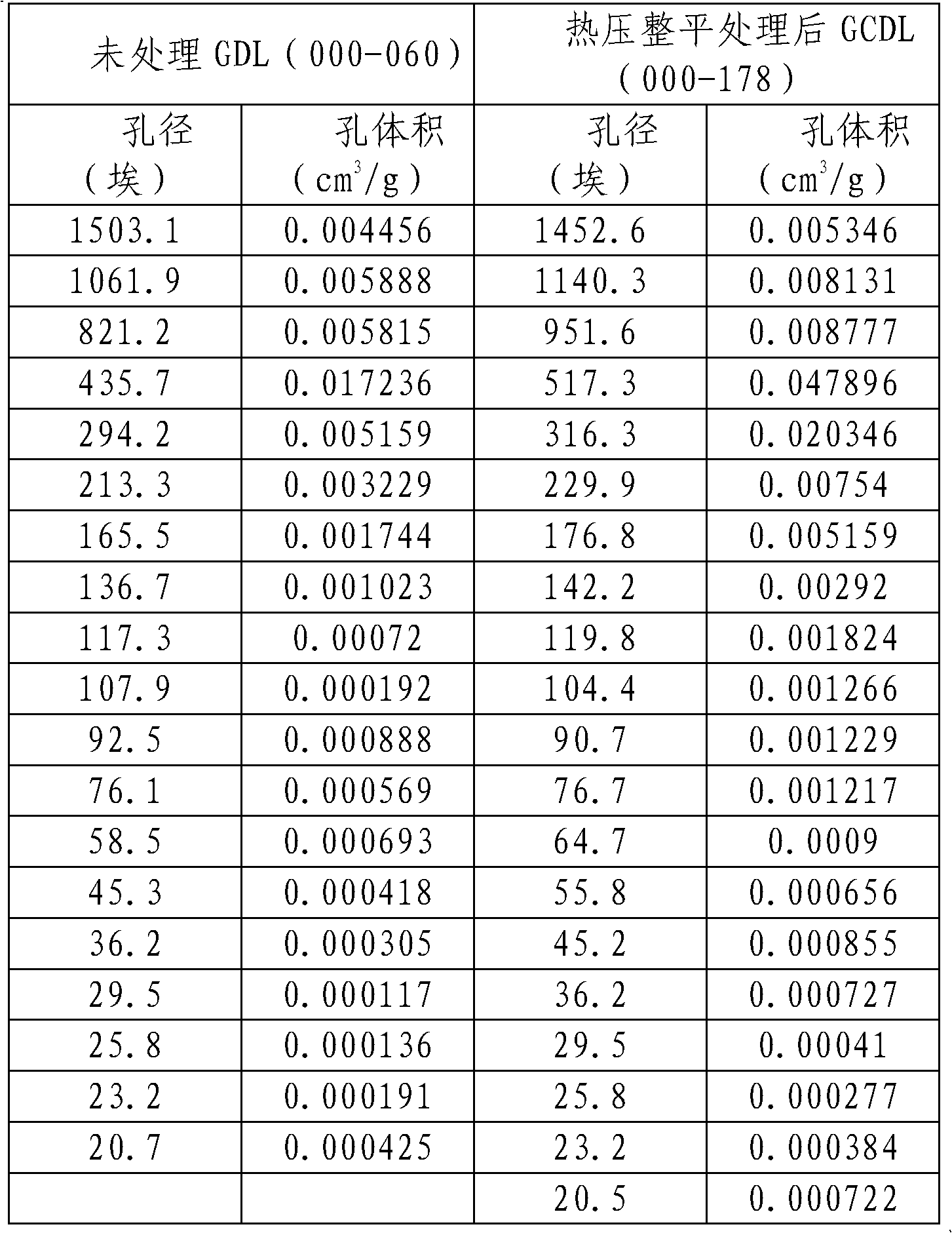

[0032] 5) In a flat vulcanizing machine at 120°C, the gas diffusion layer is hot-pressed and leveled, the pressure is controlled at 12MPa, the processing time is 30s, and then it is taken out and cooled. At this time, the thickness of the gas diffusion layer is 0.18mm, and the porosity 40%, the average pore size is 0.025μm, and the pores with a pore size of 0.01-0.05μm account for 74.65% of the total pore volume;

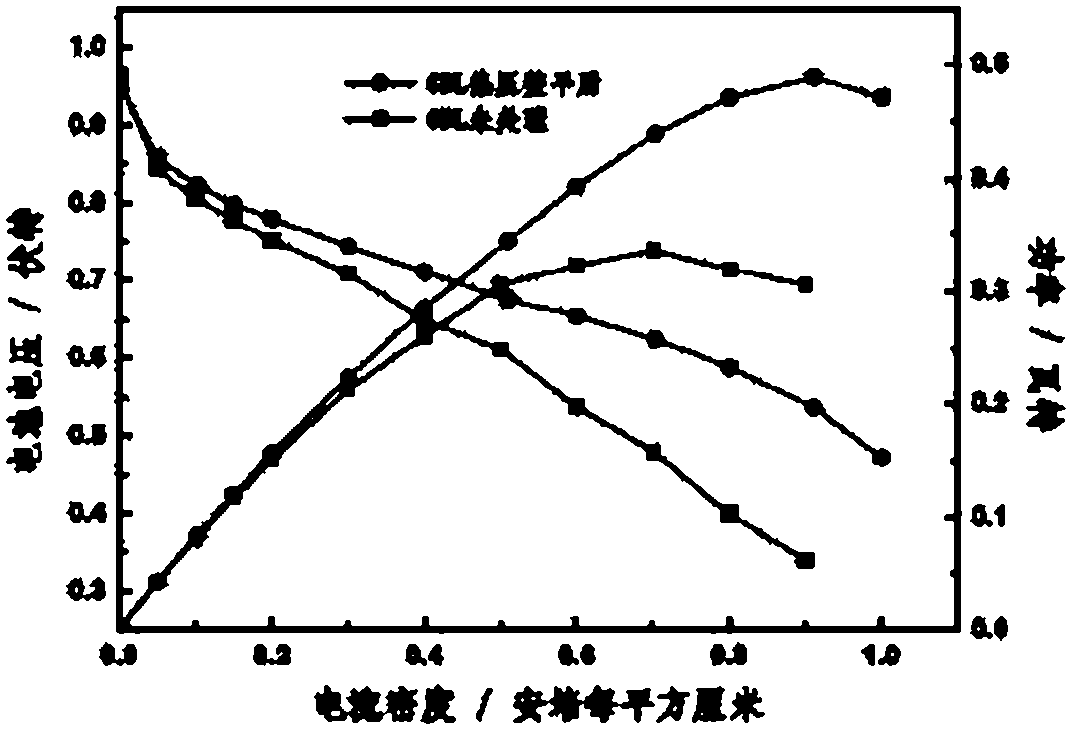

[0033] 6) The gas diffusion layer treated in 5) is hot-pressed with a piece of NF1135 membrane and anode to form a three-in-one membrane electrode, and the hot-pressing conditions are the same as those of the comparative example. figure 2The middle red curve is the discharge performance of the three-in-one membrane electrode (MEA) prepared according to this example under the condition of using hydrogen and air as the reaction gas. It can be seen from the figure that the maximum output power density of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com