Preparation method of heterogeneous visible photocatalyst

A visible light and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve good degradation effect, stable particles, and novel design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

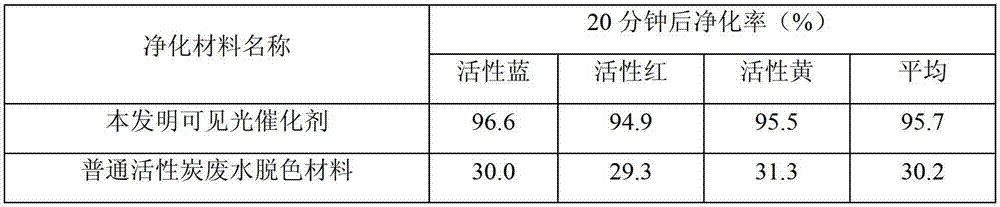

Examples

Embodiment 1

[0029] (1) Preparation of Solution A

[0030] Add 5g of bismuth nitrate and 2.1g of citric acid into 100ml of nitric acid solution (2mol / L), stir until the solution is uniform and transparent, add dropwise a mixed solution of 1.2g of ammonium metavanadate and 1g of polyethylene glycol 2000 (PEG), and control The dropping rate was 3mL / min, and stirred at a speed of 300rpm for 2h to obtain solution A;

[0031] (2) Preparation of Suspension B

[0032] Adjust the pH of solution A to 8.5 with sodium hydroxide, raise the temperature to 90°C, and stir at a speed of 300rpm for 3h to obtain suspension B;

[0033] (3) Preparation of bismuth vanadate

[0034] Vacuum filter the suspension B, rinse the filter product with deionized water, dry at 70°C, and calcined at 500°C to obtain bismuth vanadate (BiVO 4 ) micronanoparticles;

[0035] (4) Preparation of Solution C

[0036] Will get BiVO 4 Add the particles into 100ml of silver nitrate solution with a concentration of 0.5g / L, sonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com