Fixture used for moulding of proton exchange membrane fuel cell membrane electrode and preparation method for proton exchange membrane fuel cell membrane electrode

A technology of proton exchange membrane and fuel cell membrane, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable electrochemical performance of proton exchange membrane fuel cells, affecting discharge performance, poor bonding strength of membrane electrodes, etc., to achieve Effects of improved electrochemical performance, excellent discharge performance, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The invention provides a method for preparing a membrane electrode of a proton exchange membrane fuel cell, comprising:

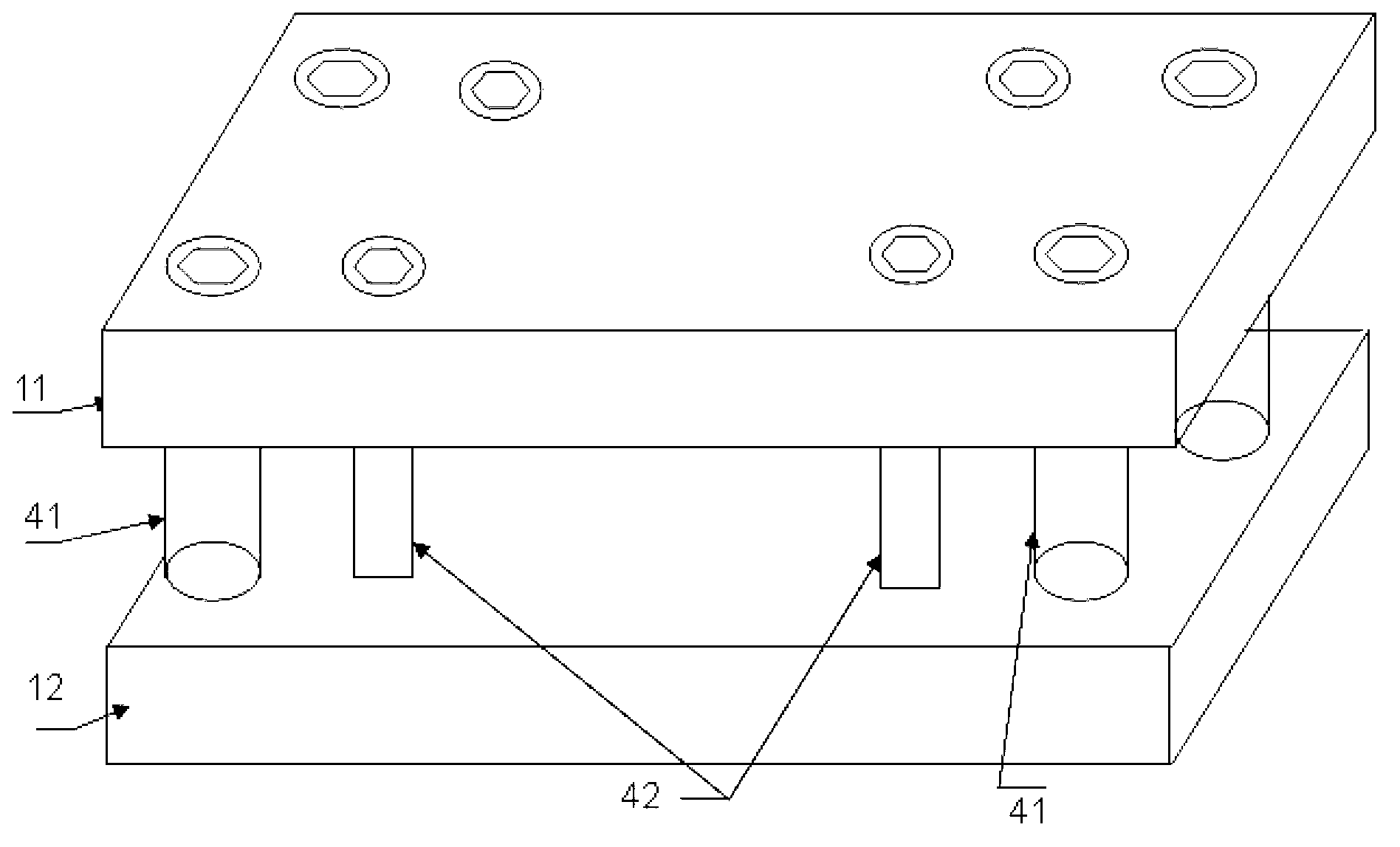

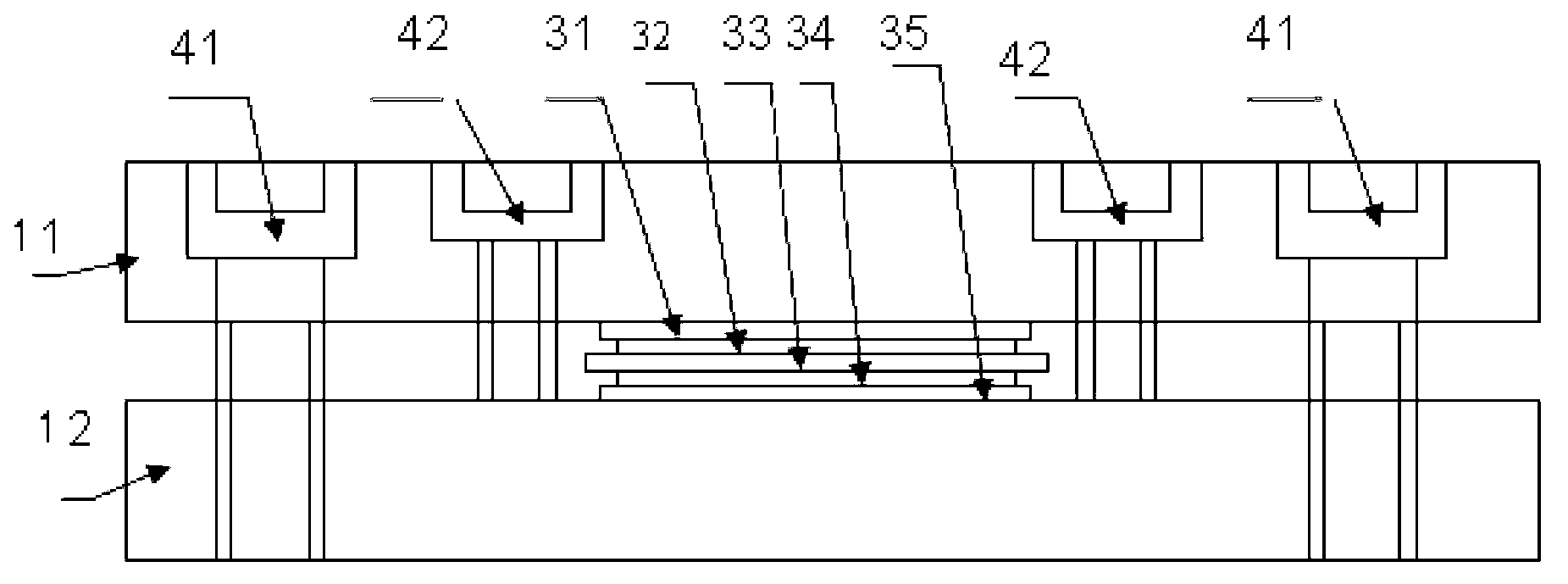

[0057] The anode diffusion layer, the anode catalyst layer, the proton exchange membrane layer, the cathode catalyst layer, and the cathode diffusion layer are sequentially placed between the first flat plate and the second flat plate placed in parallel, and the first flat plate and the second flat plate are provided with through hole, the screw rod connects the first plate and the second plate through the through hole;

[0058] The torque of the screw rod is set to 0.5N·m~5N·m, the first plate is provided with a screw hole, and the set screw rod tightens the second plate through the screw hole to complete the fixation;

[0059] The fixed first plate, the second plate, and the anode diffusion layer, anode catalyst layer, proton exchange membrane layer, cathode catalyst layer, and cathode diffusion layer placed between the first plate and the second p...

Embodiment 1

[0085] Spray 5mg / cm on a piece of 2cm×7cm anode carbon paper 2 Platinum ruthenium black catalyst to obtain catalyst anode layer; Spray coating 5mg / cm2 on another 2cm×7cm cathode carbon paper 2 Platinum black catalyst, to obtain the catalyst cathode layer; these two carbon papers are placed on both sides of a 3cm × 10cm Nafion115 membrane (purchased from DuPont), the catalyst is in contact with the Nafion115 membrane respectively, and then these membrane electrode assemblies are placed At figure 1 Between the first flat plate and the second flat plate of the clamp shown, both flat plates are made of steel plates;

[0086] The torque of the screw that connects and fixes the two plates is set to 1N·m~1.3N·m, the first plate is provided with a screw hole, and the set screw rod tightens the second plate through the screw hole, complete fixation;

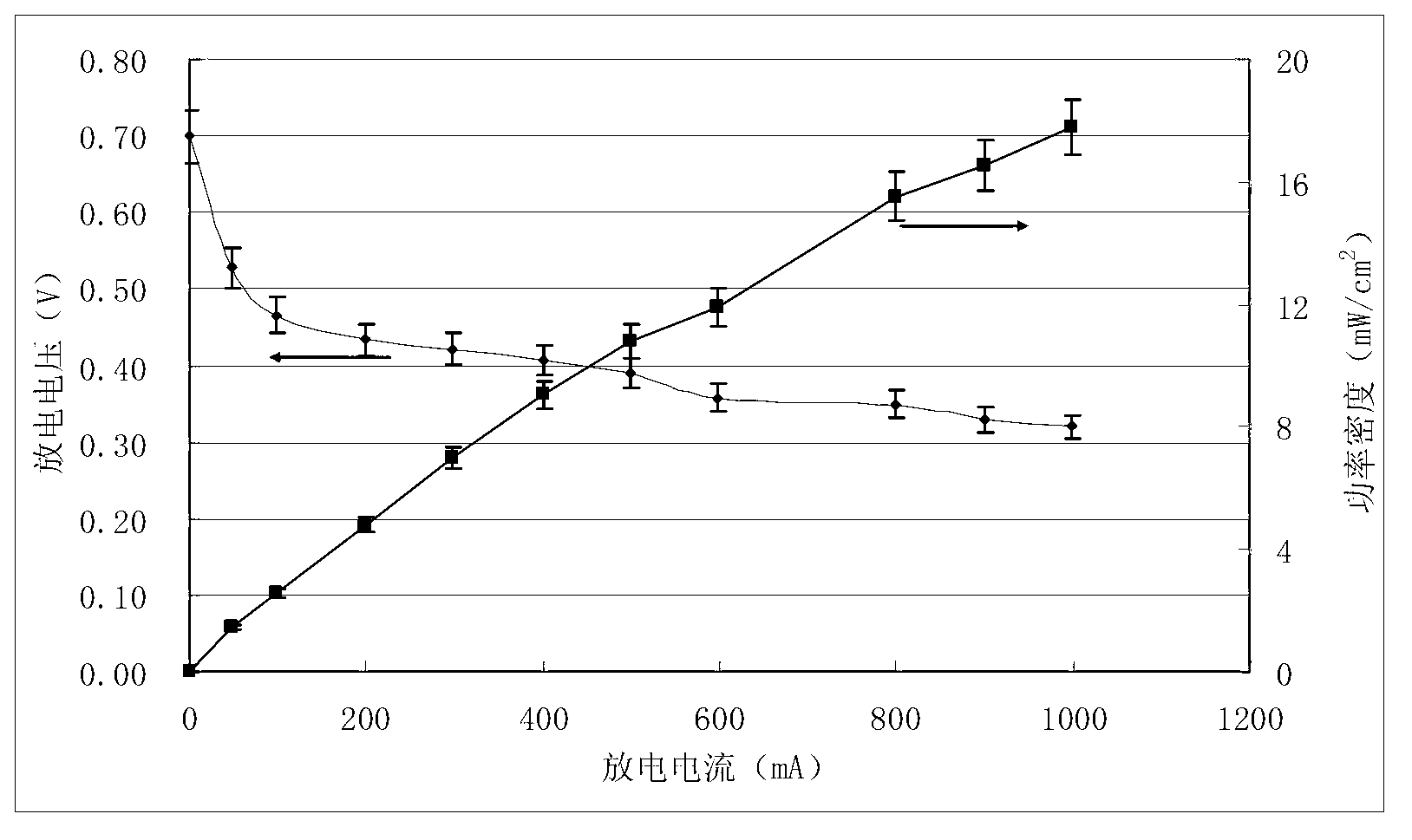

[0087] Place the clamps with each assembly of the membrane electrode on a flat plate molding machine, heat at 200°C for 10 minutes, t...

Embodiment 2

[0090] Spray 2mg / cm on a piece of 2cm×2cm anode carbon paper 2 Platinum ruthenium black catalyst to obtain catalyst anode layer; spray 2mg / cm2 on another 2cm×2cm cathode carbon paper 2 Platinum black catalyst, to obtain the catalyst cathode layer; these two carbon papers are placed on both sides of a 3cm × 3cm Nafion117 membrane (purchased from DuPont), the catalyst is in contact with the Nafion117 membrane respectively, and then these membrane electrode assemblies are placed At figure 1 Between the first flat plate and the second flat plate of the fixture shown, both flat plates are made of alloy aluminum plates;

[0091] The torque of the screw rod that connects and fixes the two plates is set to 0.8N·m~1N·m, the first plate is provided with a screw hole, and the set screw rod tightens the second plate through the screw hole, complete fixation;

[0092] Place the fixed clamps with the membrane electrode components on a flat plate molding machine, heat at 240°C for 5 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com