Oxide powder and preparation method thereof as well as catalyst and carrier thereof

A technology of oxide powder and oxide, which is applied in the direction of catalyst carrier, oxide/hydroxide preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of complicated and complicated process, and achieve the benefit of diffusion , low density, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

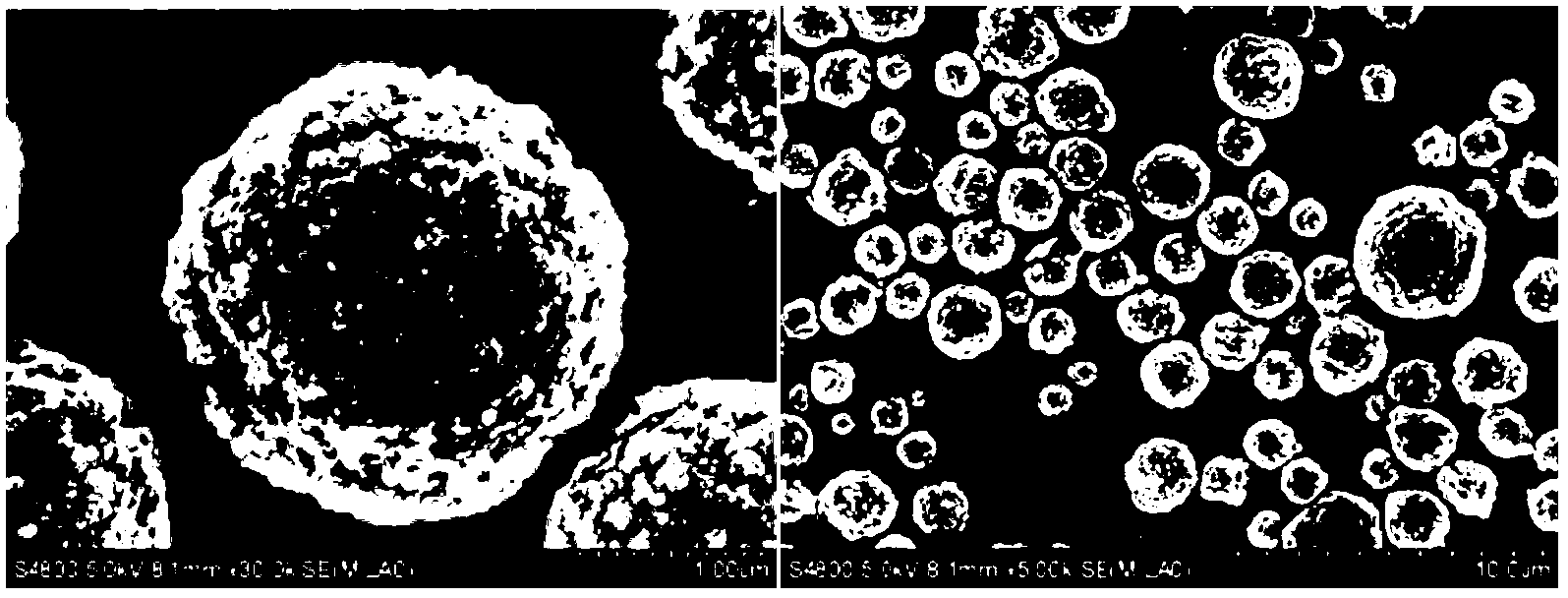

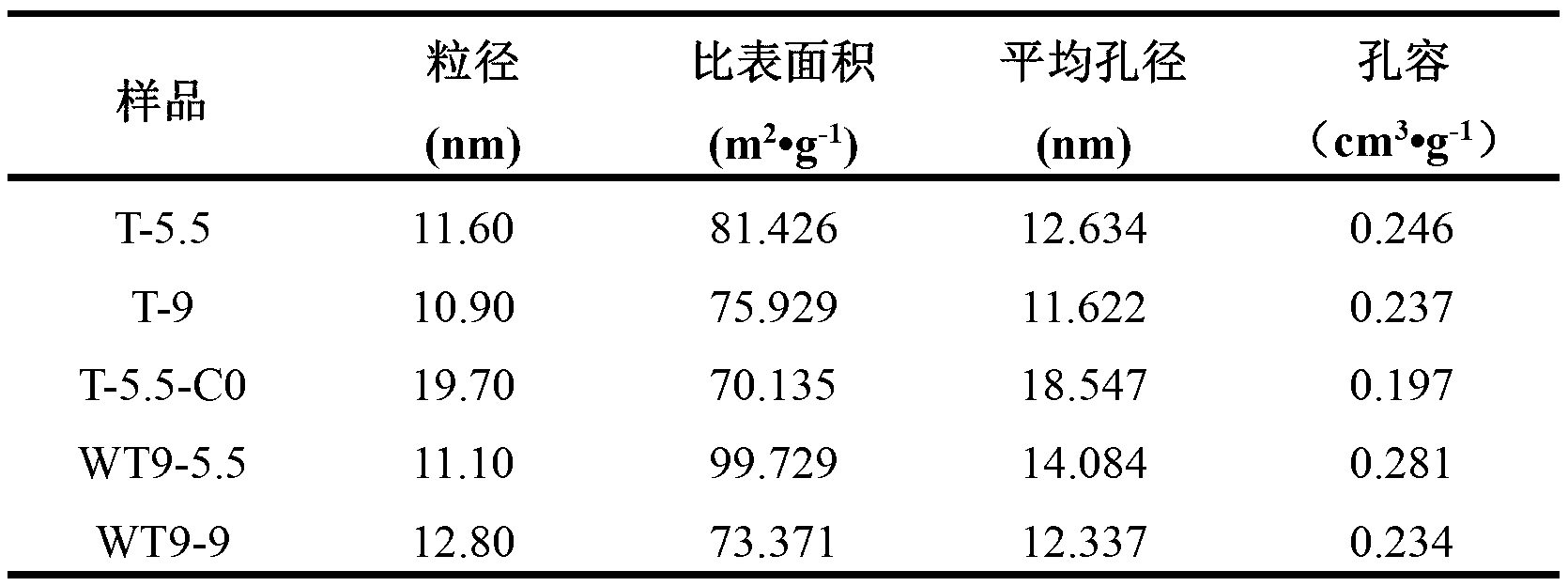

Embodiment 1

[0046] Add a certain amount of titanyl sulfate to the aqueous solution of CTAB (0.4g / L) at room temperature, stir for 12 hours and then filter to obtain titanyl sulfate solution (solid content 5wt%), add ammonia water (ammonia water concentration 28%) to pH = 5.5 to obtain Slurry A1; Slurry A1 was washed three times with CTAB aqueous solution (0.4g / L), and the obtained solid phase filter cake was added to CTAB aqueous solution (0.4g / L) and ammonia water (ammonia concentration 28%) was added to adjust the pH to 5.5 , ultrasonicated at 50kHZ for 1h, aged at 80°C for 6h, spray-dried at 220°C (feed speed: 0.3m 3 / hour), roasted at 550°C for 3h to obtain white TiO 2 powder (labeled T-5.5).

Embodiment 2

[0048] The preparation conditions and procedures were the same as in Example 1, and the pH was adjusted to 9 to obtain white TiO2 powder (marked as T-9).

Embodiment 3

[0050] The preparation conditions and preparation procedures are the same as in Example 1, and the CTAB content of the CTAB aqueous solution is changed to 0g / L to obtain white TiO 2 powder (labeled T-5.5-C0).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com