Starting and running method of completely autotrophic ammonium removal over nitrite technology

A technology of whole-process autotrophic denitrification and operation method, applied in the field of water environment restoration and regeneration, can solve problems such as high nitrogen removal load, and achieve the effect of improving oxygen mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

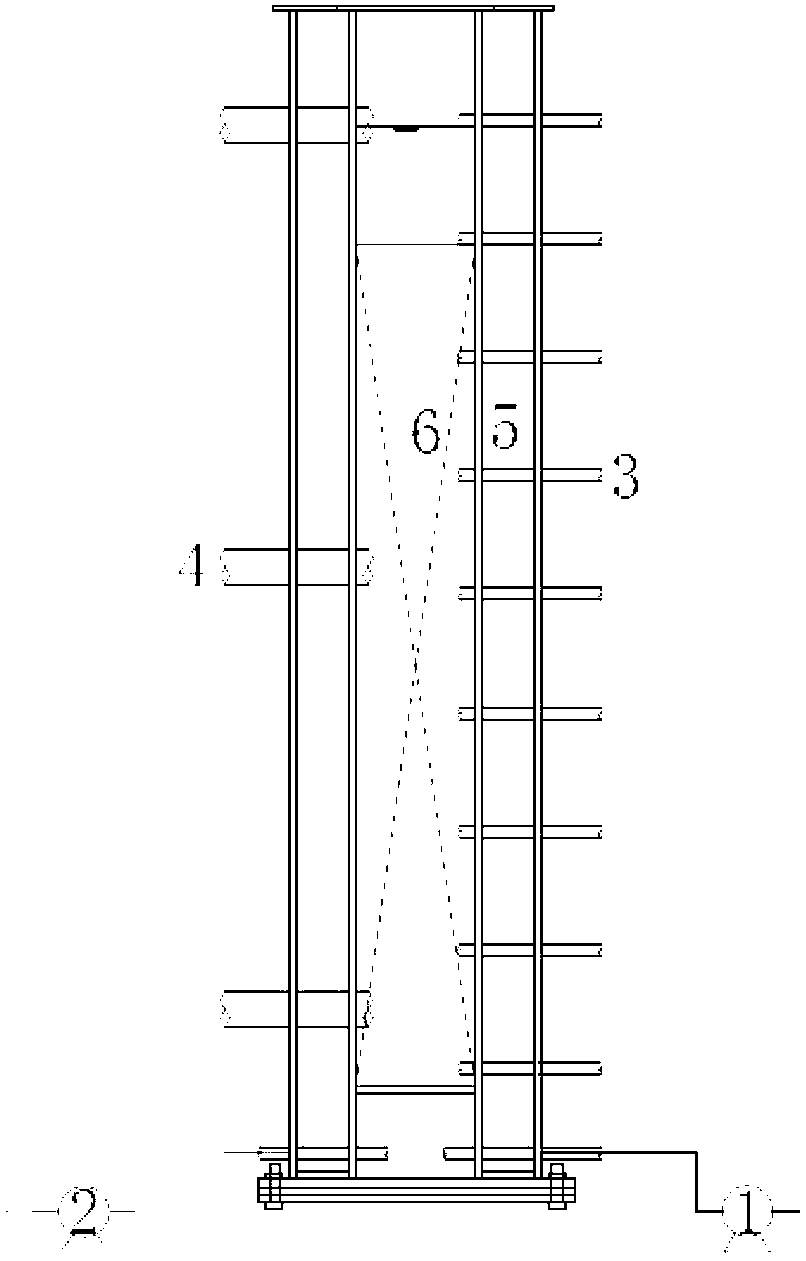

[0025] The test uses an upflow volcanic rock filled biofilter reactor, such as figure 1 shown. The reactor is made of plexiglass, with an inner diameter of 9.4cm and a height of 100cm. There is a water bath outside, and the temperature of the water bath is controlled at 24°C to 28°C. The total volume of the reactor is 5.3L, and the effective volume is 2.63L. The column is filled with graded volcanic rock filler, the filling height is 0.7m, the filling particle size from bottom to top is 10-12mm, 8-10mm, and the filling height is 0.4m and 0.3m respectively. There is a sampling port every 100mm on the wall of the filter tank, a water outlet at the top end, and a feeding port on the other side of the filter column. An aeration device is installed at the bottom of the reactor, and the aeration volume is controlled by a rotameter.

[0026] The reactor inoculation laboratory currently has mixed sludge of nitrosation and anaerobic ammonium oxidation with a mass ratio of 5:1, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com