Method for recycling solvent during poly-para-phenylene terephthalamide reaction

A technology of poly-p-phenylene terephthalamide and p-phenylene phthalamide is applied in the field of polymer material synthesis, and can solve the problem of unsolved calcium chloride recycling, difficult recycling of calcium chloride, salt Unable to recycle and other problems, to achieve the effect of reducing energy consumption, realizing recycling and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

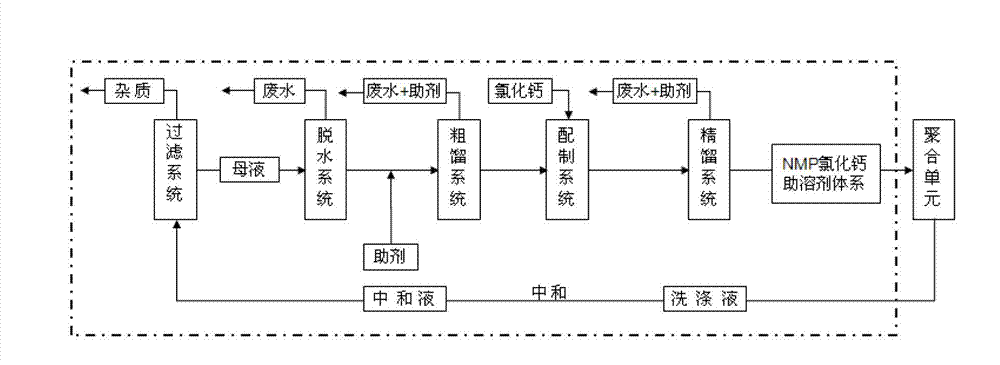

Image

Examples

Embodiment 1

[0018] In this embodiment, the solvent is recycled through the following steps: add calcium hydroxide to the washing solution to obtain a neutralizing solution with pH=7, pass the neutralizing solution through a bag filter with a filtration accuracy of 5um, and collect the filtrate in a storage tank , Send the filtrate to the dehydration system for dehydration by vacuum distillation. The distillation parameters are absolute pressure 2KPa and temperature 70°C. The dehydration system can remove most of the water. Then add 2% ethanol additive to the solution, and send the solution into the crude distillation system, control the absolute pressure in the crude distillation tower to 3KPa, the temperature is 90°C, and the water content in the solution after crude distillation is <0.5%. Add anhydrous calcium chloride to the solution after crude distillation to obtain a solution with a calcium chloride concentration of 0.13 mol / L, and input the solution into a rectification tower with a...

Embodiment 2

[0020] In this embodiment, the solvent is recycled through the following steps: adding calcium carbonate to the washing solution to obtain a neutralizing solution with pH=7, passing the neutralizing solution through a tubular filter with a filtration accuracy of 3um, collecting the filtrate in a storage tank, The filtrate is sent to the dehydration system for vacuum distillation and dehydration. The distillation parameters are an absolute pressure of 3KPa and a temperature of 90°C. Then add 0.5% ethanol-methanol additive to the solution, and send the solution into the crude distillation system, control the absolute pressure in the crude distillation tower to 2KPa, the temperature is 100°C, and the water content in the solution after crude distillation is <0.3%. Add anhydrous calcium chloride to the solution after crude distillation to obtain a solution with a concentration of calcium chloride of 0.15 mol / L, and input the solution into a rectification tower with an absolute pres...

Embodiment 3

[0022] In this embodiment, the solvent is recycled through the following steps: add calcium hydroxide to the washing solution to obtain a neutralizing solution with pH=7, pass the neutralizing solution through a bag filter with a filtration accuracy of 2um, and collect the filtrate in a storage tank , the filtrate is sent to the dehydration system for dehydration by vacuum distillation, the distillation parameters are an absolute pressure of 4KPa and a temperature of 80°C. Then add 1% methanol additive to the solution, and send the solution into the crude distillation system, control the absolute pressure in the crude distillation tower to 1KPa, the temperature is 80°C, and the water content in the solution after crude distillation is <0.8%. Add anhydrous calcium chloride to the crude distillation solution to obtain a solution with a calcium chloride concentration of 0.17 mol / L, and input the solution into a rectification tower with an absolute pressure of 0.8KPa and a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com