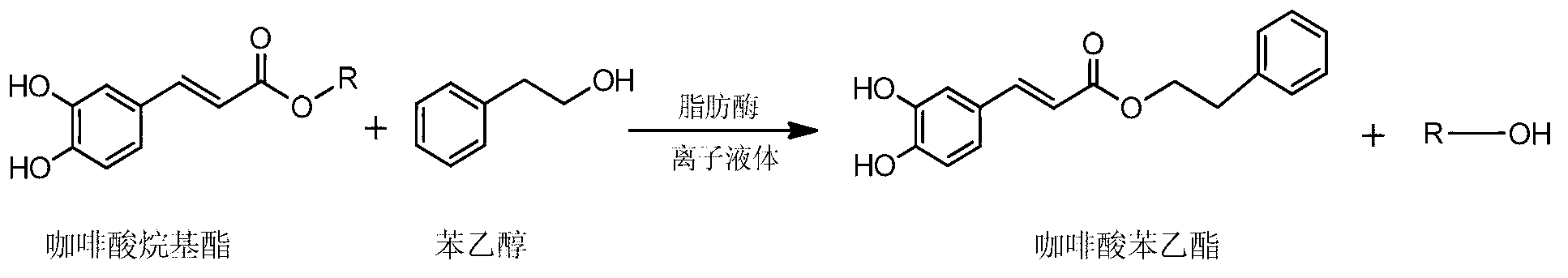

Biosynthesis method of caffeic acid phenethylester by means of transesterification

A caffeic acid phenethyl ester, biosynthesis technology, applied in the direction of fermentation, etc., to achieve the effects of less by-products, good market application prospects, and overcoming the low utilization rate of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

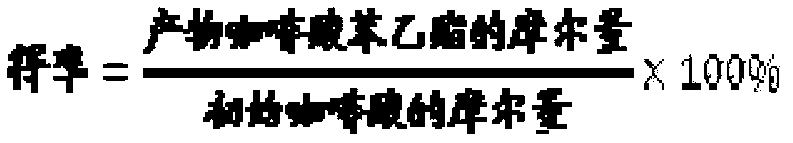

[0021] With caffeic acid heptyl ester as the reaction substrate, the molar ratio of caffeic acid heptyl ester: phenyl alcohol is 1:1, the mass ratio of caffeic acid heptyl ester: lipase Lipozyme TLIM is 1: 1, phenyl alcohol: ionic liquid [TOMA ][HSO 4 ] The volume ratio is 1:5 to prepare a reaction system, and react for 10 hours at 40°C and at a rotating speed of 120 rpm. After the reaction, the sample was tested by HPLC, and the yield of caffeic acid phenethyl ester was calculated to be 42.7%.

Embodiment 2

[0023] Using caffeic acid butyl ester as the reaction substrate, according to the molar ratio of caffeic acid butyl ester: phenethyl alcohol is 1:40, the mass ratio of caffeic acid butyl ester: lipase Novozym435 is 1:40, and phenyl alcohol: ionic liquid [Omim] [BF 4 ] The volume ratio is 1:50 to form a reaction system, and react for 48 hours at 90°C and 300 rpm. After the reaction, the sample was tested by HPLC, and the yield of caffeic acid phenethyl ester was calculated to be 71.7%.

Embodiment 3

[0025] Ethyl caffeate is used as the reaction substrate, and the molar ratio of ethyl caffeate: phenethyl alcohol is 1:14, the mass ratio of ethyl caffeate: industrial lipase is 1:30, and the mass ratio of phenethyl alcohol: ionic liquid [Bmim ][Tf 2 The volume ratio of N] is 1:20 to form a reaction system, and the reaction system is reacted for 40 hours at 70°C and at a rotation speed of 180 rpm. After the reaction, the sample was tested by HPLC, and the yield of caffeic acid phenethyl ester was calculated to be 63.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com