Preparation method of high-concentration PAM-aluminum, zinc iron composite water treatment agent

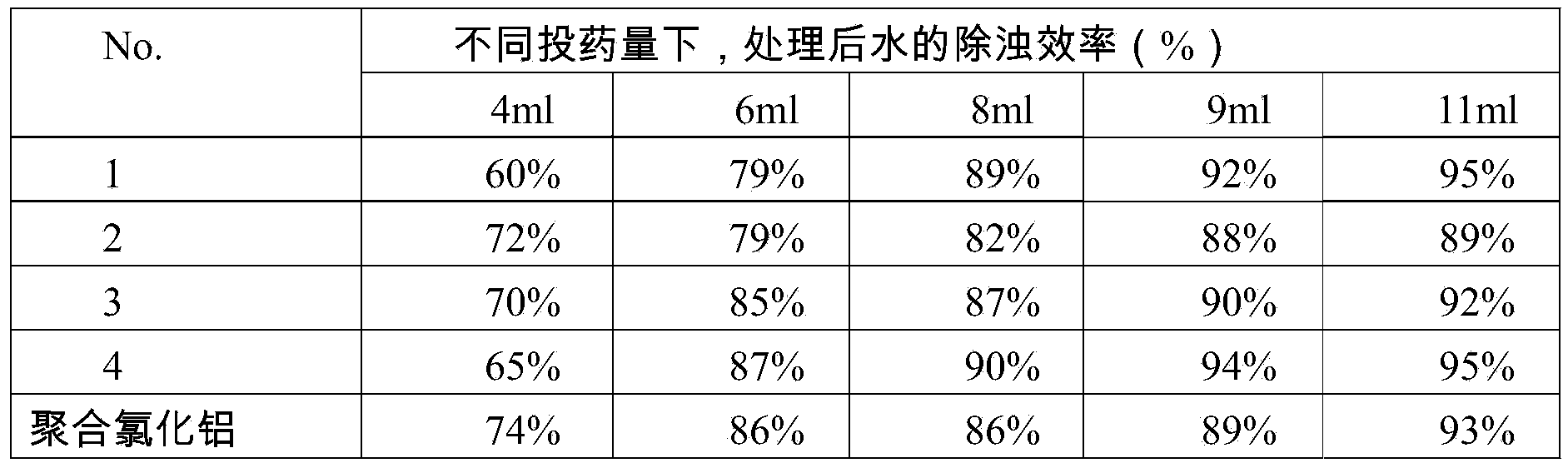

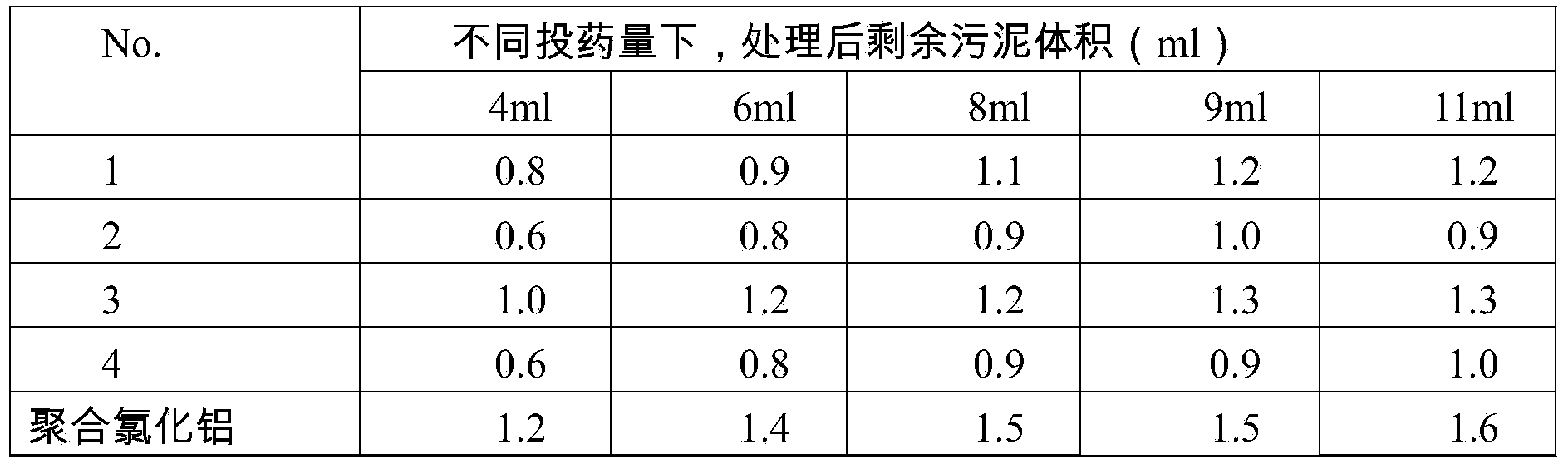

A high-concentration, water treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems that do not involve the compound function of inorganic and organic, and achieve excellent pollution removal efficiency, good stability, and sludge generation little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 7kg of galvanized slag was crushed into medium or fine slag samples by wet method. At a temperature of 70°C-100°C and a stirring speed of 200rpm-600rpm, add 12kg of dilute sulfuric acid solution (55% mass fraction) into the above block sample for leaching for 2h, and then use Filter through quartz sand with a thickness of 10 cm, and control the filtration temperature at 55° C. to 100° C. to obtain the filtrate for use. Under the condition of temperature 45℃~75℃ and stirring speed 400rpm~800rpm, add 8kg sodium hydroxide (mass fraction 45%) solution to the above filtrate, adjust the pH value to 2.5 ~3.5, stop stirring, carry out polymerization reaction, polymerization time is 0.25 hours, and obtain colorless liquid semi-product. Mix 6.2kg of polyacrylamide solution (0.5% by mass) with the above colorless liquid semi-product at a temperature of 35°C to 45°C and a stirring speed of 400 to 800 rpm, and then add 6kg of sodium hydroxide (mass fraction: 20%) solution, adjust ...

Embodiment 2

[0023] 11kg of galvanized slag was crushed into medium slag or fine slag samples by wet method. At a temperature of 70°C-100°C and a stirring speed of 200-600 rpm, add 17kg of dilute sulfuric acid solution (mass fraction 40%) into the above block sample for leaching for 3 hours, and then use Filter through quartz sand with a thickness of 20 cm, and control the filtration temperature to 55° C. to 100° C. to obtain a filtrate for use. Add 14kg of sodium hydroxide (50% by mass) solution to the above filtrate at a temperature of 45°C to 75°C and a stirring speed of 400 to 800 rpm to adjust the pH to 2 ~3, stop stirring, carry out polymerization reaction, the polymerization time is 0.5 hour, obtain colorless liquid semi-product. Mix 6.4kg of polyacrylamide solution (0.3% by mass) with the above colorless liquid semi-product at a temperature of 35°C-45°C and a stirring speed of 400rpm-800rpm, and then add 13kg of sodium hydroxide (mass fraction 20%) solution, adjust the pH value t...

Embodiment 3

[0025]15kg of galvanized slag was crushed into medium or fine slag samples by wet method. At a temperature of 70°C to 100°C and a stirring speed of 200 to 600 rpm, add 24kg of dilute sulfuric acid solution (70% mass fraction) into the above block sample for leaching for 5 hours, and then use Filter through quartz sand with a thickness of 10 cm, and control the filtration temperature at 55° C. to 100° C. to obtain the filtrate for use. Add 19kg of sodium hydroxide (45% by mass) solution to the above filtrate at a temperature of 45°C to 75°C and a stirring speed of 400 to 800 rpm to adjust the pH to 3.5 ~4, stop stirring, carry out polymerization reaction, the polymerization time is 0.5 hours, and obtain a colorless liquid semi-product. At a temperature of 35°C-45°C and a stirring speed of 400-800 rpm, mix 13kg of polyacrylamide solution (0.6% by mass) with the above-mentioned colorless liquid semi-product, and then add 21kg Sodium hydroxide (mass fraction: 15%) solution, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com