High-toughness epoxy-resin nanocomposite composition and preparation method thereof

A nano-composite material and epoxy resin technology, applied in the direction of fatty acid production, fatty acid chemical modification, etc., to achieve the effects of improving machinability, toughness, and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Castor oil (industrial product, Beihai Cereals and Oils Industry Co., Ltd.): glacial acetic acid (analytical pure, Tianjin Damao Chemical Reagent Company)=1.0: 2.5 is added to reactor in molar ratio, then add catalyst ion exchange resin (analytical pure, Tianjin Regent Co., Ltd.) and solvent toluene (analytical grade, Tianjin Damao Chemical Reagent Co., Ltd.), stirred and heated up to 45°C, dripped hydrogen peroxide (analytical grade, Yantai Shuangshuang Chemical Co., Ltd.), heated up to 55°C, and reacted for 7 hours . Wash the upper oil layer with 5% sodium bicarbonate (analytical grade, Tianjin Damao Chemical Reagent Co., Ltd.) aqueous solution and deionized water, and distill under reduced pressure to obtain epoxy castor oil.

[0028] Pyrazine (analytical pure, Alfa Aisha Chemical Co., Ltd.): benzyl bromide (analytical pure, Sinopharm Chemical Reagent Co., Ltd.)=1.0: 1.1 is added to the reactor in molar ratio, and then solvent acetonitrile (analytical pure, Tianjin, ...

Embodiment 2

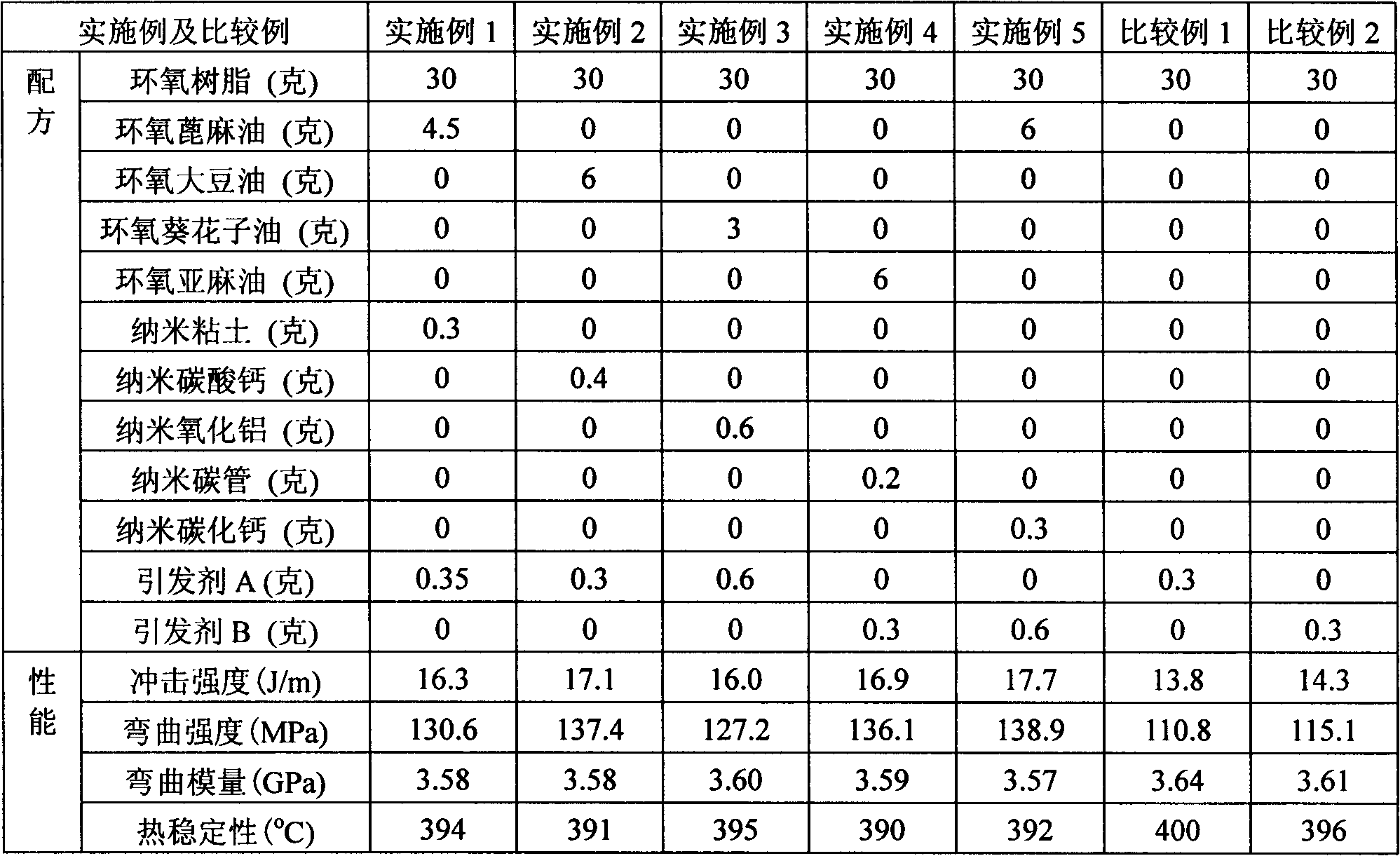

[0032] Except that castor oil is changed into soybean oil, and nano-clay is changed into nano-calcium carbonate, all the other are the same as embodiment 1. The components and test results of epoxy resin nanocomposites are shown in Table 1.

Embodiment 3

[0034] Except changing castor oil into sunflower oil, nano clay into nano aluminum oxide, all the other are the same as embodiment 1. The components and test results of epoxy resin nanocomposites are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com