Thermo-sensitive sand consolidation, channeling sealing and well completion integrated chemical system used for steam injection for thermal recovery

A temperature-sensitive, steam-injecting technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of cumbersome construction process, loss of consolidation effect, difficulty in producing heavy oil in oilfields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

[0031] Embodiment 1~16, chemical system formula orthogonal experiment

[0032]The influence of each factor on the performance of the chemical system at high temperature was comprehensively investigated by using 5 factors and 4 levels of orthogonal experiment. In the experiment, furfuryl alcohol prepolymer products with different viscosities were used (named F1, F2, F3, and F4, and their viscosities were 77mPa s, 64mPa s, 56mPa s, 49mPa s respectively), and B was temperature selective curing. agent (taking carbon tetrachloride as an example, the selective curing temperature is 120°C, and the dosage is 6, 7, 8, 9% of the weight of the furfuryl alcohol prepolymer; C is pyridine, and the dosage is 0, 1% of the weight of the furfuryl alcohol prepolymer , 3, 5%; D is butyl acetate, the dosage is 0, 3, 6, 9% of the weight of furfuryl alcohol prepolymer; E is resorcinol, the dosage is 0, 0.2, 0.4, 0.6%; Carry out 16 formula orthogonal experiments altogether, investigate the influence...

Embodiment 17

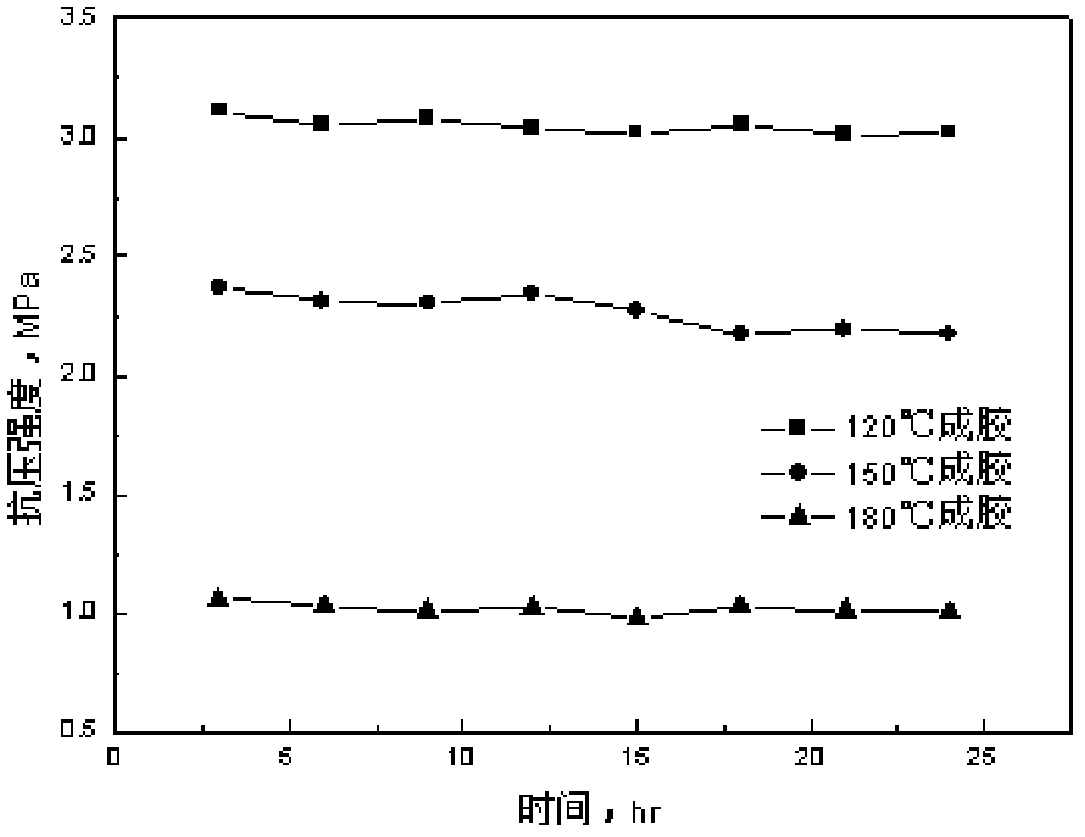

[0033] Embodiment 17, thermal stability test

[0034] Put the colloids of the CP-1 system consolidated at 120°C, 150°C and 180°C respectively in a high-temperature furnace at 300°C for 24 hours, take them out regularly to cool to room temperature, measure the strength of the colloid, and investigate its thermal stability sex, the experimental results see figure 1 .

[0035] Depend on figure 1 The experimental results show that the colloids of the CP-1 system consolidated at 120°C, 150°C and 180°C have little change in the strength of the colloid after thermal aging at 300°C for 24 hours. The colloids consolidated under the conditions of ℃, 150℃ and 180℃ all have good heat resistance.

example 18

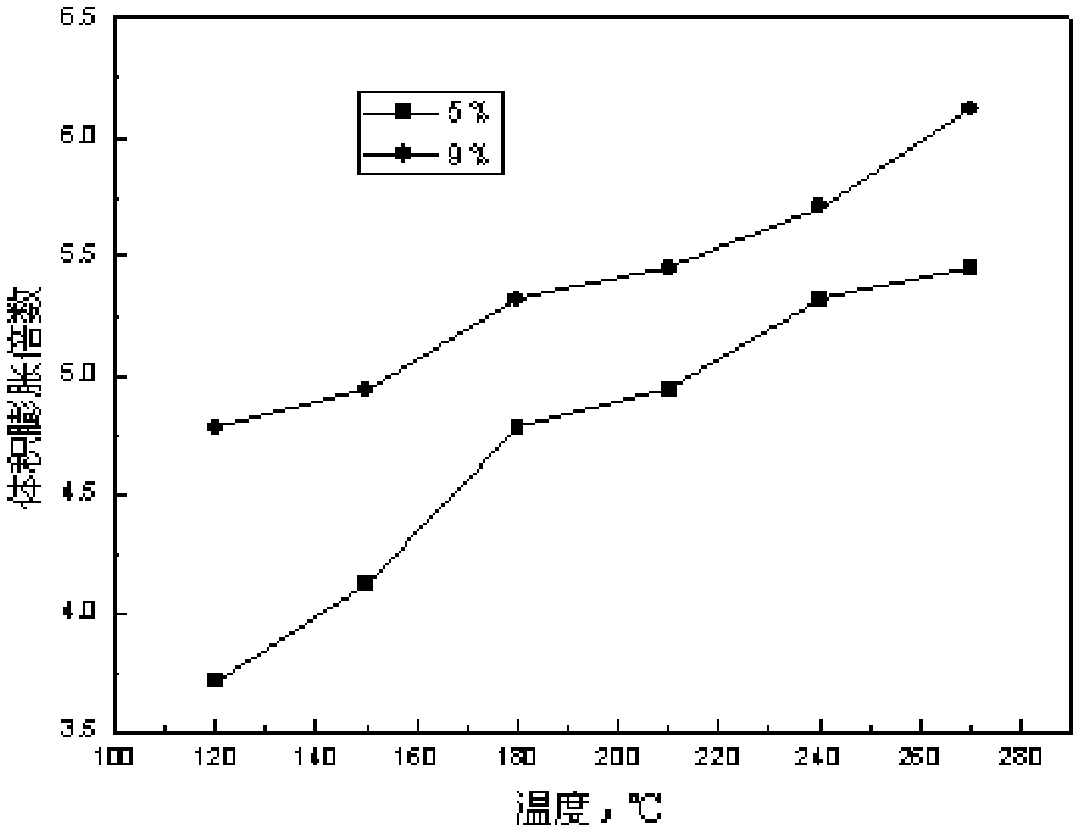

[0036] Example 18. Relationship between consolidation strength and expansion volume at different consolidation temperatures

[0037] Calculate the expansion volume multiple of 20mL of the chemical system with the mass fraction of curing agent 5% and 9% after being solidified at different temperatures. The calculation method is as follows: calculate the volume of the raw solidified body under the above-mentioned different temperatures through the diameter of the Teflon cylinder and the height of the raw solidified body, and divide the calculated volume of the colloid by the volume (20mL) of the chemical system stock solution to get The expansion volume multiple after consolidation at different temperatures, the relationship between consolidation temperature and expansion volume is shown in figure 2 shown.

[0038] Such as figure 2 As shown, with the increase of the mass fraction of the curing agent in the chemical system, the volume expansion multiple of the consolidated bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com