Aluminum and aluminum alloy surface self-repairing and corrosion-resisting conversion coating and preparation method thereof

A conversion coating and alloy technology, applied in the coating process of metal materials, etc., can solve the problem of self-healing and anti-corrosion properties of 8-hydroxyquinoline/hydrotalcite composite conversion coatings, and achieve self-healing and anti-corrosion coatings The effect of outstanding performance, novel ideas and novel methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

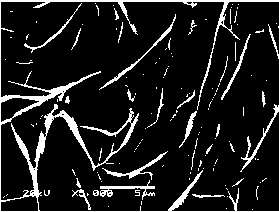

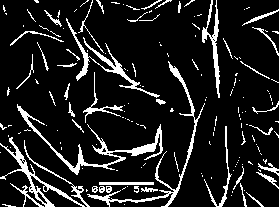

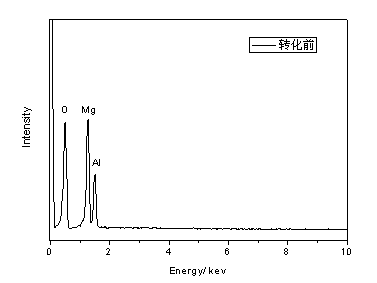

[0032] A method for preparing a self-healing anti-corrosion composite conversion coating on the surface of aluminum and its alloys, including the preparation of a magnesium-aluminum hydrotalcite conversion coating and a composite conversion coating. The specific process is as follows:

[0033] The first step is to prepare magnesium-aluminum hydrotalcite conversion coating for later use: aluminum and its alloys are polished step by step with 600, 1000, 1500, and 2000 sandpaper, then washed with water to remove impurities, ultrasonically cleaned in isopropanol to remove oil, and washed with deionized water. According to the ratio of magnesium nitrate and ammonium nitrate 1:5, prepare 100ml solution and put it in the reaction kettle, adjust the pH to 9 with dilute ammonia water, place the aluminum sheet vertically in the reaction kettle, and take it out after 48 hours of constant temperature reaction in an oven at 100°C , rinse and blow dry.

[0034] The second step, the preparat...

Embodiment 2

[0036] A method for preparing a self-healing anti-corrosion composite conversion coating on the surface of aluminum and its alloys, including the preparation of a magnesium-aluminum hydrotalcite conversion coating and a composite conversion coating. The specific process is as follows:

[0037] The first step is to prepare magnesium-aluminum hydrotalcite conversion coating for later use: aluminum and its alloys are polished step by step with 600, 1000, 1500, and 2000 sandpaper, then washed with water to remove impurities, ultrasonically cleaned in isopropanol to remove oil, and washed with deionized water. According to the ratio of magnesium nitrate and ammonium nitrate as 1:7, prepare 100ml solution and put it in the reaction kettle, adjust the pH to 9 with dilute ammonia water, place the aluminum sheet vertically in the reaction kettle, and take it out after 48 hours of constant temperature reaction in an oven at 90°C , rinse and blow dry.

[0038] The second step, the prepar...

Embodiment 3

[0040] A method for preparing a self-healing anti-corrosion composite conversion coating on the surface of aluminum and its alloys, including the preparation of a magnesium aluminum hydrotalcite conversion coating and a composite conversion coating. The specific process is as follows:

[0041] The first step is to prepare magnesium-aluminum hydrotalcite conversion coating for later use: aluminum and its alloys are polished step by step with 600, 1000, 1500 and 2000 sandpaper, then washed with water to remove impurities, ultrasonically cleaned in isopropanol to remove oil, and washed with deionized water. Prepare 100ml of solution according to the ratio of magnesium nitrate and ammonium nitrate as 1:10 and put it in the reaction kettle, adjust the pH to 9 with dilute ammonia water, place the aluminum sheet vertically in the reaction kettle, and take it out after 48 hours of constant temperature reaction in an oven at 120°C , rinse and blow dry.

[0042]The second step, the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com