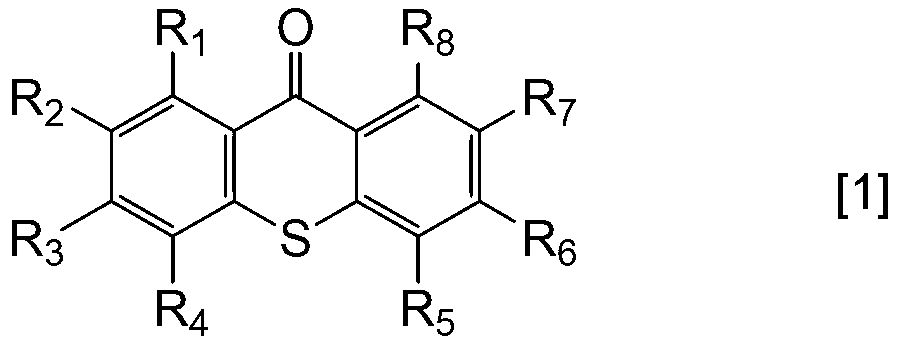

Thioxanthone compound and organic light emitting element having the same

A technology of organic light-emitting element and thioxanthone, applied in the field of thioxanthone compound and organic light-emitting element, can solve problems such as shallow LUMO energy level, and achieve the effect of low driving voltage and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Synthesis of Exemplary Compound A-1

[0117]

[0118] A 200-mL recovery flask was charged with the following reactants and solvents:

[0119] F-1: 1.85g (5mmol)

[0120] F-2 (phenylboronic acid): 1.5g (12mmol)

[0121] Tetrakis(triphenylphosphine)palladium(0): 137mg (0.12mmol)

[0122] Toluene: 50mL

[0123] Ethanol: 20mL

[0124] Sodium carbonate aqueous solution (concentration: 30% by weight): 30 mL

[0125] Then, the atmosphere in the reaction system was replaced with a nitrogen atmosphere, and then, the reaction solution was stirred under reflux for 3 hours. After the reaction was completed, water was added to the reaction solution and further stirred, and deposited crystals were filtered off. Then, the crystals were successively washed with water, ethanol and acetone to obtain a crude product. Then, the crude product was heated and dissolved in toluene, and filtered hot, and then, recrystallized twice with toluene solvent to obtain purified crystals. The...

Embodiment 2

[0132] Synthesis of Exemplified Compound A-3

[0133]

[0134] A 200-mL recovery flask was charged with the following reactants and solvents:

[0135] F-1: 1.85g (5mmol)

[0136] F-3 (3-biphenylboronic acid): 2.4g (12mmol)

[0137] Tetrakis(triphenylphosphine)palladium(0): 137mg (0.12mmol)

[0138] Toluene: 50mL

[0139] Ethanol: 20mL

[0140] Sodium carbonate aqueous solution (concentration: 30% by weight): 30 mL

[0141] Then, the atmosphere in the reaction system was replaced with a nitrogen atmosphere, and then, the reaction solution was stirred under reflux for 3 hours. After the reaction was completed, water was added to the reaction solution and further stirred, and deposited crystals were filtered off. Then, the crystals were successively washed with water, ethanol and acetone to obtain a crude product. Then, the crude product was heated and dissolved in toluene, and filtered hot, and then, recrystallized twice with toluene solvent to obtain purified crystals...

Embodiment 3

[0146] Synthesis of Exemplified Compound A-5

[0147]

[0148] A 200-mL recovery flask was charged with the following reactants and solvents:

[0149] F-1: 1.85g (5mmol)

[0150] F-4: 4.3g (12mmol)

[0151] Tetrakis(triphenylphosphine)palladium(0): 137mg (0.12mmol)

[0152] Toluene: 50mL

[0153] Ethanol: 20mL

[0154] Sodium carbonate aqueous solution (concentration: 30% by weight): 30 mL

[0155] Then, the atmosphere in the reaction system was replaced with a nitrogen atmosphere, and then, the reaction solution was stirred under reflux for 3 hours. After the reaction was completed, water was added to the reaction solution and further stirred, and deposited crystals were filtered off. Then, the crystals were successively washed with water, ethanol and acetone to obtain a crude product. Then, the crude product was heated and dissolved in chlorobenzene, and filtered hot, and then, recrystallized twice with a chlorobenzene solvent to obtain purified crystals. Then, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com