Layered self-assembled medicine controlled-release system based on star polymer, and preparation method thereof

A layer-by-layer self-assembly and star-shaped polymer technology, applied in drug delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as intelligent responsiveness, unsatisfactory drug release performance, and narrow application range , to achieve the effect of facilitating industrial production, expanding the scope of application, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

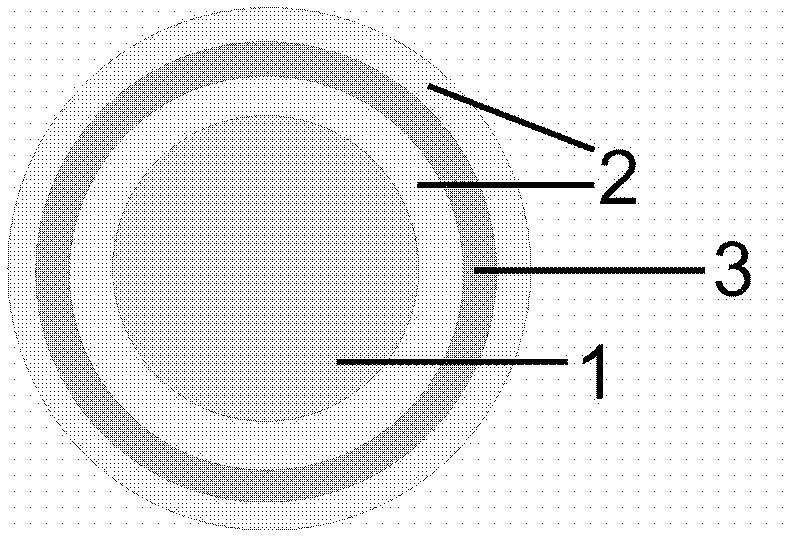

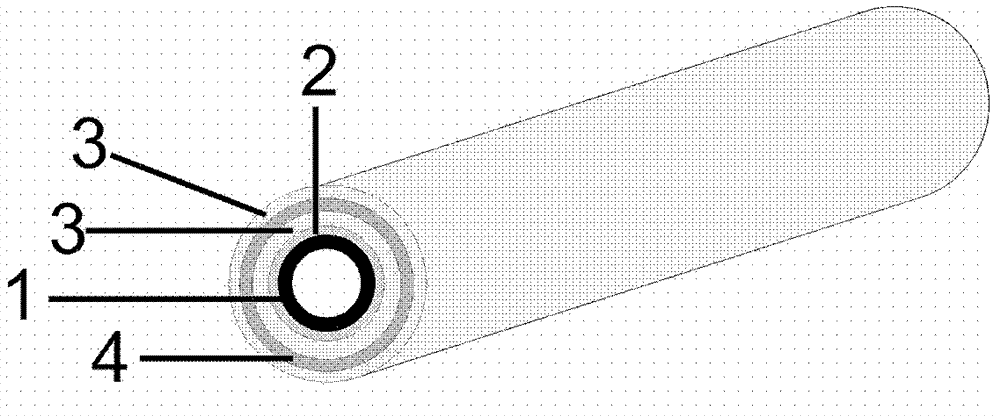

[0053] The processing steps of the present embodiment are as follows:

[0054] (1) Preparation of raw material solution

[0055] A star-shaped polymer with a molecular weight of 190kda and 21 arms: methacrylic acid-N,N-dimethylaminoethyl ester polymer (abbreviated as PDMAEMA in the following description) is formulated with an aqueous hydrochloric acid solution with a pH value of 5 to a concentration of 1mg / mL solution, then add NaCl, the amount of NaCl added is limited to 0.2mol / L in the mixed solution;

[0056] Insulin (abbreviated as INS in the following description) powder was prepared into an INS solution with a concentration of 1 mg / mL with an aqueous hydrochloric acid solution with a pH of 4, and then adjusted to a pH of 6.6 ± 0.1 with a NaOH solution with a concentration of 0.1 mol / L (insulin isoelectric point above);

[0057] Glucose oxidase (abbreviated as GOD in the following description) powder is formulated into a GOD solution with a concentration of 2 mg / mL with...

Embodiment 2

[0064] The processing steps of the present embodiment are as follows:

[0065] (1) Preparation of raw material solution

[0066] Raw material solution and preparation method thereof are identical with embodiment 1.

[0067] (2) Treat the substrate

[0068] The substrate is the same as in Example 1, and the processing method for the substrate is the same as in Example 1.

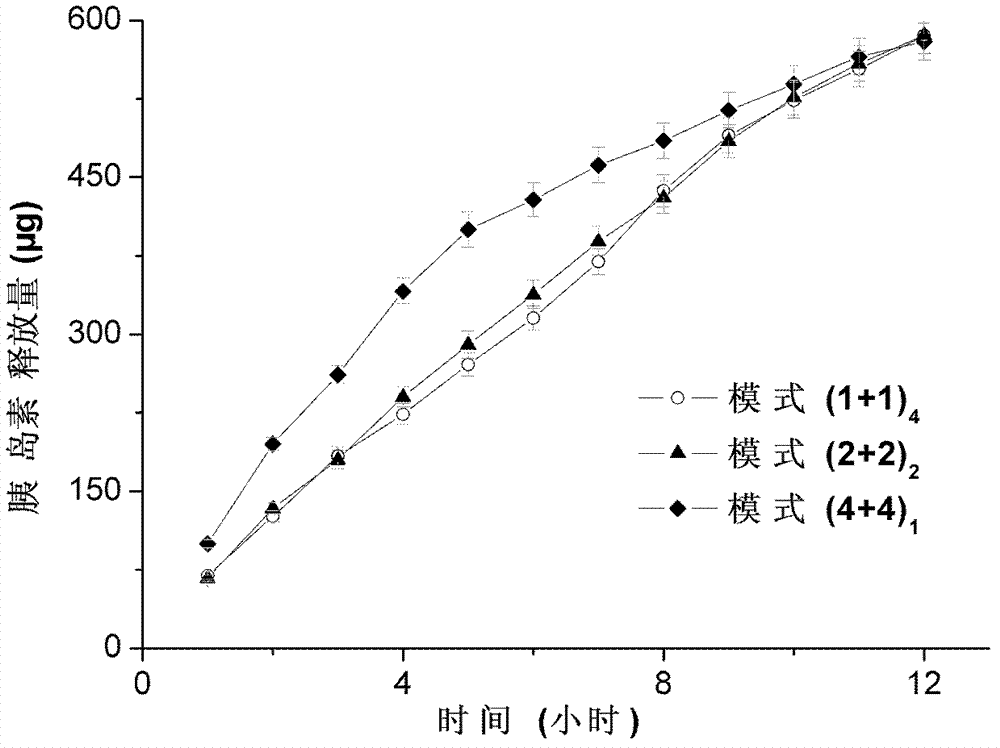

[0069] (3) Assembling the cladding

[0070] In the layer-by-layer self-assembled drug controlled release system based on the star polymer prepared in this example, the coating order of the PDMAEMA layer, the INS layer, and the GOD layer on the substrate is: [(PDMAEMA / INS) 1 +(PDMAEMA / GOD) 1 ] Y +PDMAEMA, where Y=4,8,12. The layer-by-layer self-assembled drug controlled release system obtained when Y=4 is defined as the mode (1+1) 4 .

[0071] According to the above structure, at room temperature and normal pressure, 200 μL of the PDMAEMA solution prepared in step (1) was coated on the surface of the s...

Embodiment 3

[0073] The processing steps of the present embodiment are as follows:

[0074] (1) Preparation of raw material solution

[0075] Raw material solution and preparation method thereof are identical with embodiment 1.

[0076] (2) Treat the substrate

[0077] The substrate is the same as in Example 1, and the processing method for the substrate is the same as in Example 1.

[0078] (3) Assembling the cladding

[0079] In the layer-by-layer self-assembled drug controlled release system based on the star polymer prepared in this example, the coating order of the PDMAEMA layer, the INS layer, and the GOD layer on the substrate is: [(PDMAEMA / INS) 2 +(PDMAEMA / GOD) 2 ] Z +PDMAEMA, where Z=2,4,6. The layer-by-layer self-assembled drug controlled release system obtained when Z=2 is defined as the mode (2+2) 2 .

[0080] According to the above structure, at room temperature and normal pressure, 200 μL of the PDMAEMA solution prepared in step (1) was coated on the surface of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com