Device of preparing nano powder material through electrical explosion

A nano-powder, electric explosion technology, applied in the field of technology, can solve the problem of small single output and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of carbon-coated nanomaterials

[0037] The test materials are iron wire (diameter φ1mm, purity 99.9%) and carbon powder (particle size 5μm, purity 99.9%).

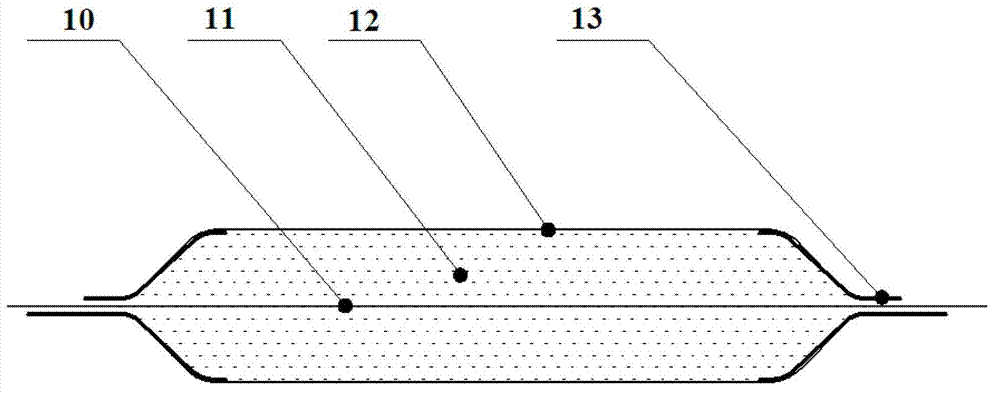

[0038] Figure 4 It is a schematic diagram of the reactant structure, wherein the electric explosion wire 10 is an iron wire, and the material of the heat-shrinkable tube 12 is PET (C 8 h 10 o 5 ), the preparation method of the reactant is as follows:

[0039] Insert the iron wire into the heat-shrinkable tube 12 , and the two ends of the iron wire expose the heat-shrinkable tube 12 ; fix the copper sheet 13 on one end of the heat-shrinkable tube 12 and then heat it so that it shrinks and wraps the copper sheet 13 tightly. Pour the carbon powder 11 from the other end of the heat-shrinkable tube 12 and fix the copper sheet 13 at this end, heat it to shrink and wrap the copper sheet 13 tightly, so as to prepare the sample required for the test.

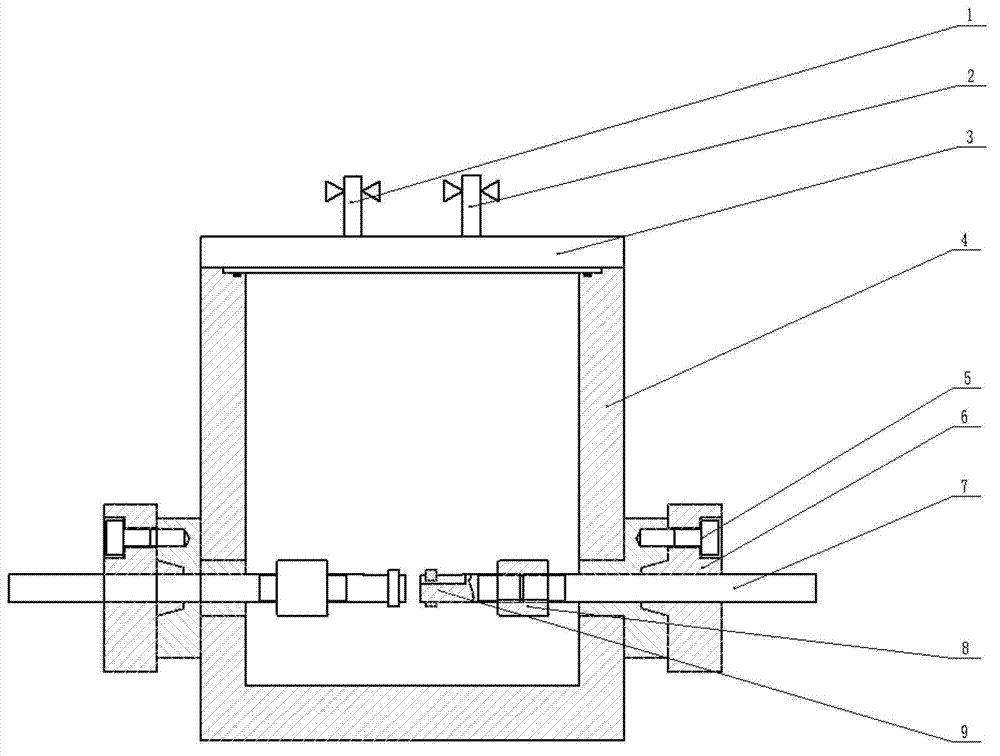

[0040] use figure 2 In the shown device, s...

Embodiment 2

[0042] Embodiment 2 prepares nano-diamond

[0043] The test material is a high-purity graphite carbon rod (diameter 2mm, length 25mm, purity 99.9%).

[0044] use figure 2 For the shown device, select the electrode holder 9 with a mounting groove at the front end, install the high-purity graphite carbon rod between the two electrode holders 9, pour water or absolute ethanol into the electric explosion tank 4, the liquid level is 6cm. Close the tank cover 3, apply a voltage of 30KV between the two electrode chucks 9, and perform a discharge explosion.

[0045] After the experiment is completed, the liquid containing nanoparticles is discharged from the exhaust valve 2, and most of the water is removed by centrifugation, then centrifugally rinsed with absolute ethanol, dried in a vacuum oven, and sample nanoparticles are recovered.

Embodiment 3

[0046] Embodiment 3 prepares graphene

[0047] The test material is high-purity cracked graphite with a thickness of 0.5mm and a purity of 99.9%.

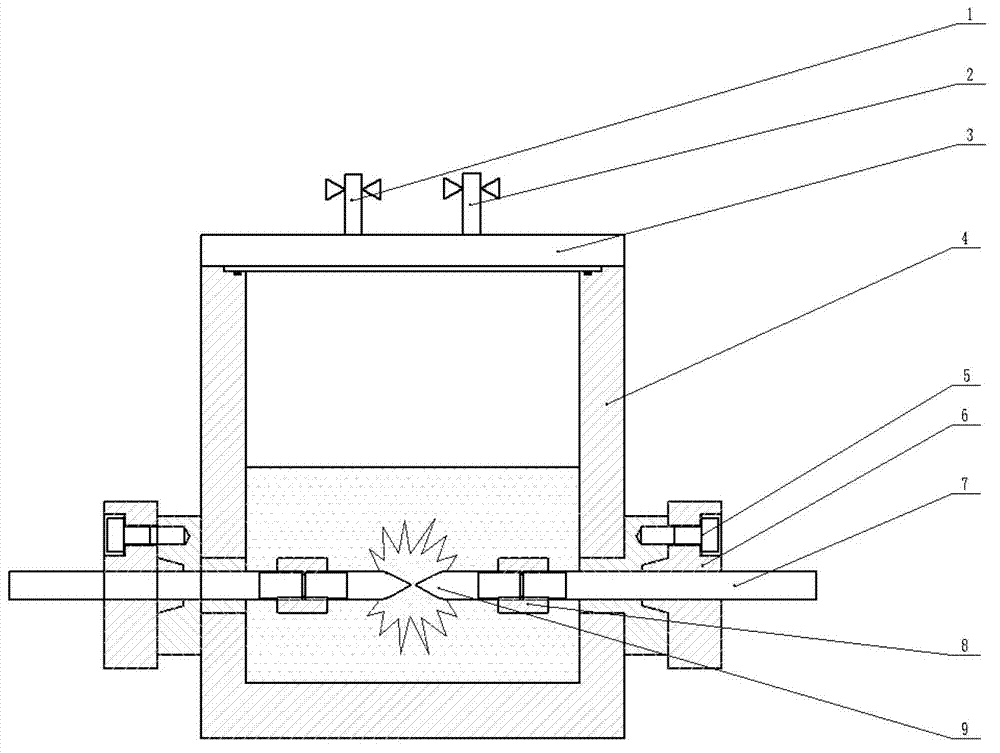

[0048] use figure 1 For the device shown, select the electrode chuck 9 with a sharp front end, and the distance between the two electrode chucks 9 is 0.5mm; pour water or absolute ethanol into the electric explosion tank, and the liquid level is 6cm. Put 100-500 mg of high-purity pyrolysis graphite into the device, and close the tank cover 3 . A voltage of 20KV is applied between the two electrode clamps 9 to make the front end of the electrode clamps 9 discharge at the tip to generate a high-energy shock wave.

[0049] After the experiment is completed, the liquid containing nanoparticles is discharged from the exhaust valve 2, and most of the water is removed by centrifugation, then centrifugally rinsed with absolute ethanol, dried in a vacuum oven, and graphene is recovered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com