Composite material for pantograph slide plate and preparing method thereof

A technology for pantograph slides and composite materials, applied to conductive materials dispersed in non-conductive inorganic materials, current collectors, electric vehicles, etc. Complicated preparation process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

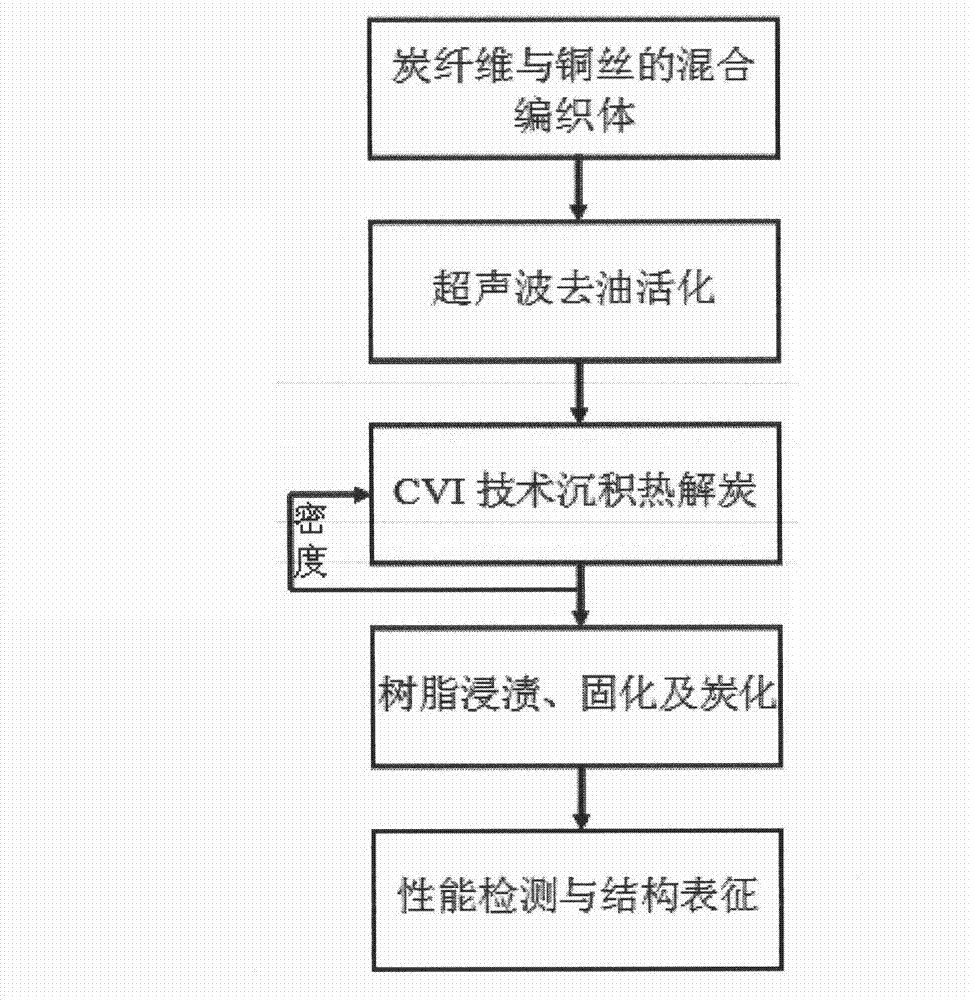

[0035] The preparation method comprises the following steps:

[0036] Step 1, performing ultrasonic degreasing and activation on the mixed braided body woven by carbon fiber 2 and copper wire 1;

[0037] Step 2, using propylene as the precursor for depositing pyrolytic carbon, with H 2 As dilution gas and furnace pressure regulating gas, the hybrid braid after ultrasonic degreasing and activation is placed in a chemical vapor deposition furnace for CVI deposition;

[0038] Step 3: Put the mixed braid deposited with pyrolytic carbon into a vacuum-pressure impregnation tank, use a thermosetting resin as an impregnating agent, and use a high-pressure impregnation process to obtain the composite material after being solidified and carbonized in sequence.

[0039] In the embodiment of the present invention, in step 1, the specific implementation method for ultrasonic degreasing and activation of the mixed braided body woven by carbon fiber 2 and copper wire 1 is as follows:

[00...

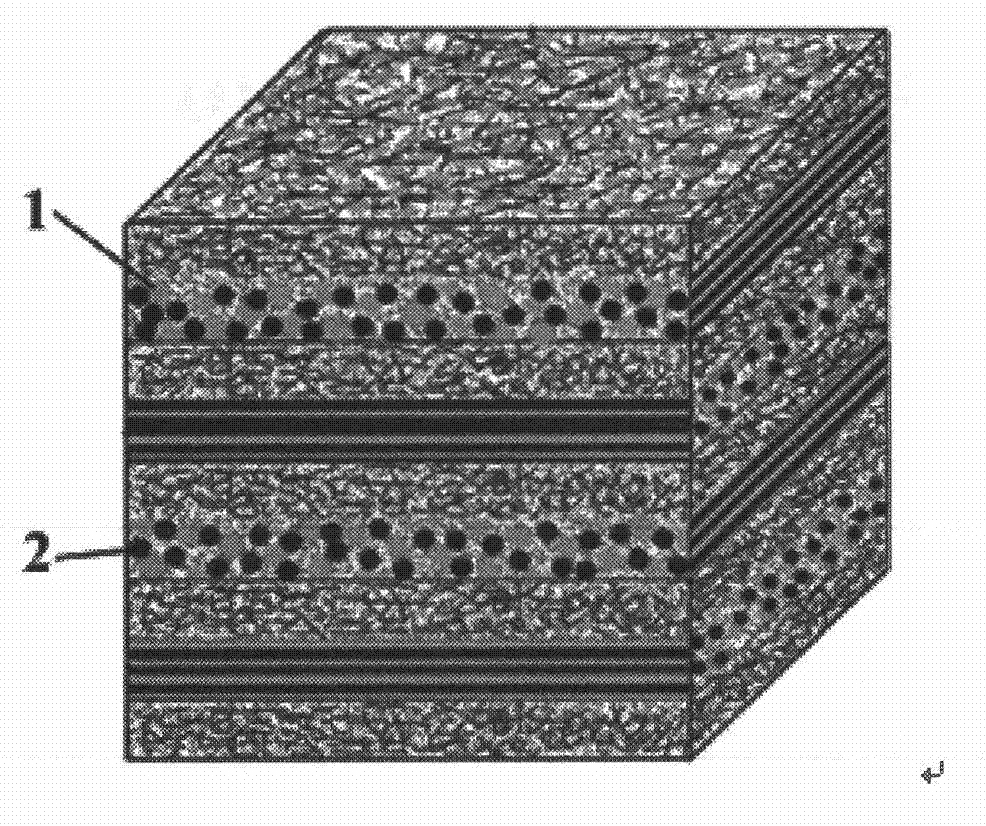

Embodiment 1

[0061] a C f / Cu-C composite material pantograph slide plate, which uses quasi-three-dimensional needle-punched carbon fiber 2 and copper wire 1 mixed braid as reinforcement, and the initial size of the braid is 100×30×25mm 3 , the initial density of the mixed braid is 1.0g / cm 3 , the mass percentage of copper contained is 25%, and the area percentage of Cu on the friction surface is 15%. The selected copper wire has a diameter of 0.1mm. Made C f / Cu-C composite material density is 1.84g / cm 3 , the resistivity is 8.12μΩ / m, the compressive strength is 168MPa, the bending strength is 121MPa, the Rockwell hardness is 53HRC, and the skateboard material is processed into a cross section of 1cm 3 , a cylindrical sample with a height of 20mm was subjected to a current-carrying friction and wear test on a self-made current-carrying friction and wear machine (ZL201220060420.5). The experimental parameters were current 200A, load 65N, and wear time 3min. It is measured that the hig...

Embodiment 2

[0067] The difference from Example 1 is that a two-step three-dimensional braided carbon fiber 2 and copper wire 1 mixed braid is used as a reinforcement, and the initial density of the mixed braid is 1.0 g / cm 3 . The single deposition time of CVI technology deposition pyrolytic carbon process is 30h. After each deposition is completed, the green body is decoked. After 3 consecutive depositions (total time is 90h), the density of the green body reaches 1.5g / cm 3 . Use furfurone as the impregnating agent, the impregnation pressure is 2MPa, and the pressure is maintained for 3h. It is then cured at 150°C, and then transferred to a carbonization furnace for carbonization treatment at a temperature of 750°C. Made C f / Cu-C composite material density is 1.96g / cm 3 , the resistivity is 5.67μΩ / m, the compressive strength is 183Mpa, the bending strength is 132Mpa, and the Rockwell hardness is 58HRC. The current-carrying friction and wear test is carried out on the self-made frict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com