Production method for sargassum liquid fertilizer

A production method and technology of seaweed liquid, applied in directions such as organic fertilizers, can solve the problems of waste of nutrients in seaweed slag and insufficient utilization of plant nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: the production of a kind of seaweed liquid fertilizer

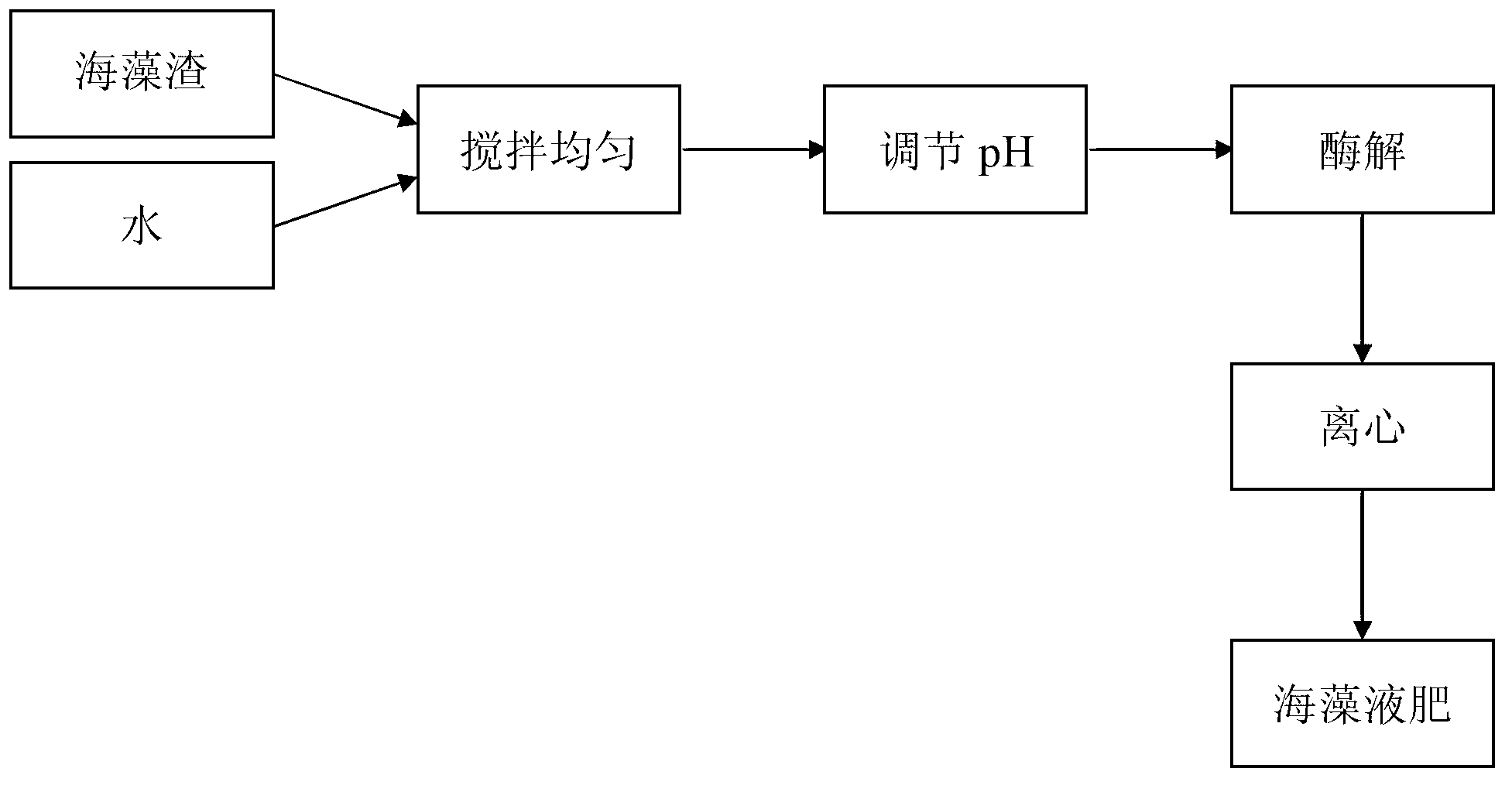

[0071] The steps of the production method are as follows:

[0072] This example uses the kelp obtained after extraction of alginic acid kelp Slag, using the method described in this manual to analyze its kelp The slag contains 2% alginic acid and 38% organic matter based on its dry weight.

[0073] A, according to the weight ratio of kelp slag and water 1:5, said kelp slag is added to the water, fully stirred and mixed;

[0074] B, using concentrated hydrochloric acid to adjust the pH of the mixed solution obtained in step A to 6.8;

[0075] C. Add a compound enzyme to the mixture obtained in step B according to the amount of the compound enzyme being 0.05% of the weight of the kelp slag, and perform enzymatic hydrolysis at a temperature of 32° C. for 24 hours.

[0076] The compound enzyme is 30 parts by weight of cellulase sold by Sukehan (Weifang) Bioengineering Co., Ltd., 30 parts by weight...

Embodiment 2

[0080] Embodiment 2: the production of a kind of seaweed liquid fertilizer

[0081] The steps of the production method are as follows:

[0082] In this example, the residue obtained after extracting alginic acid from Sargassum was used, and the Sargassum residue contained 3% alginic acid and 40% organic matter by dry weight based on the analysis method described in this manual.

[0083] A, according to the weight ratio of sargassum and water 1:1, the sargassum residue is added to the water, fully stirred and mixed;

[0084] B, using concentrated hydrochloric acid to adjust the pH of the mixed solution obtained in step A to 7.2;

[0085] C. Add a compound enzyme to the mixture obtained in step B according to the amount of the compound enzyme being 0.5% of the weight of the sargassum residue, and carry out enzymatic hydrolysis at a temperature of 30° C. for 28 hours.

[0086] The compound enzyme is composed of 10 parts by weight of cellulase sold by Sukehan (Weifang) Bioengine...

Embodiment 3

[0090] Embodiment 3: the production of a kind of seaweed liquid fertilizer

[0091] The steps of the production method are as follows:

[0092] In this example, the residue obtained after extracting mannitol from Ascophyllum nodosum was used, and the Ascophyllum nodosum residue was analyzed by the method described in this manual to contain 2.8% alginic acid and 30% organic matter based on its dry weight.

[0093] A, according to the weight ratio of the Ascophyllum leaf algae residue and water 1:3, add the described Ascophyllum leaf algae residue into the water, fully stir and mix evenly;

[0094] B, using concentrated hydrochloric acid to adjust the pH of the mixed solution obtained in step A to 7.0;

[0095] C. Add a compound enzyme to the mixture obtained in step B according to the amount of the compound enzyme being 0.4% of the weight of the Ascophyllum leaf algae residue, and carry out enzymatic hydrolysis at a temperature of 35° C. for 25 hours.

[0096] The compound en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com