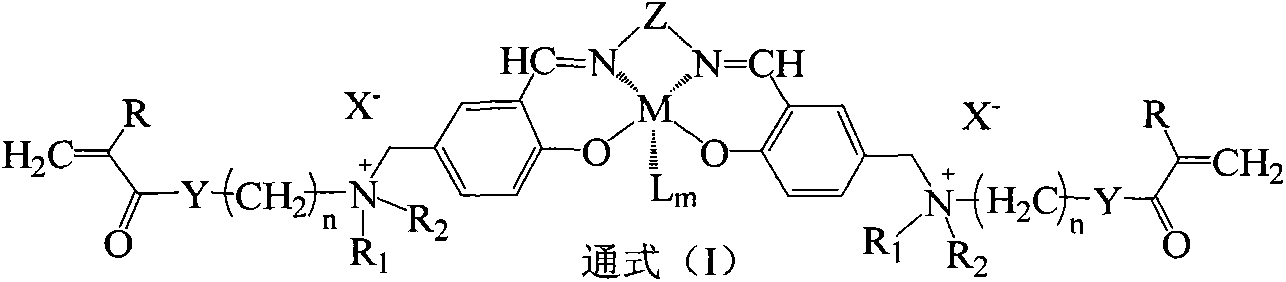

Functional monomer and preparation method thereof

A technology of functional monomer and general formula, applied in the field of functional polymer materials, can solve the problems of inability to meet the requirements of template recognition, difficult template imprinting and recognition, single function of functional monomer, etc., and achieves safe and convenient use and no three waste pollution. , a rich source of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

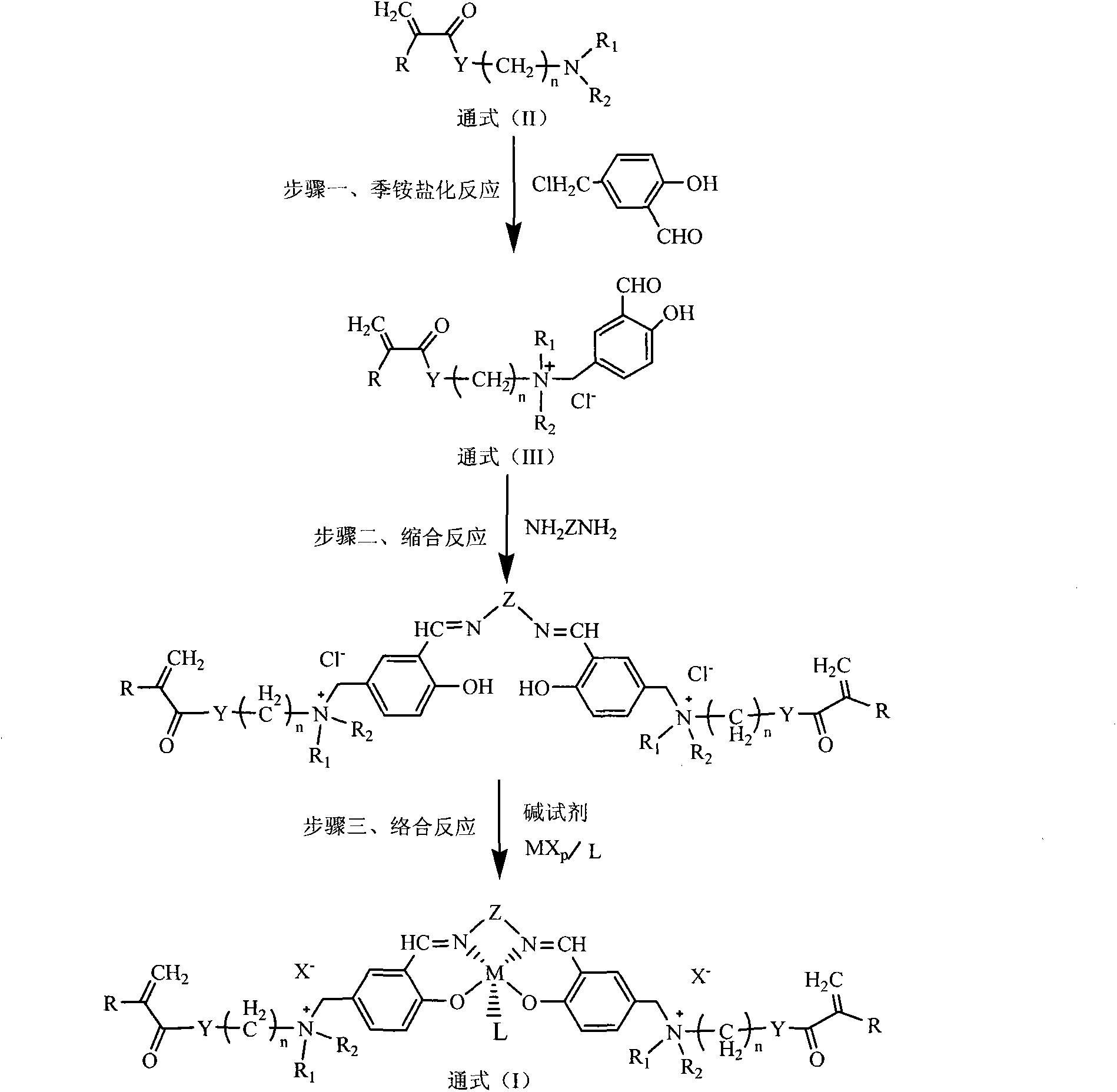

Method used

Image

Examples

Embodiment 1D

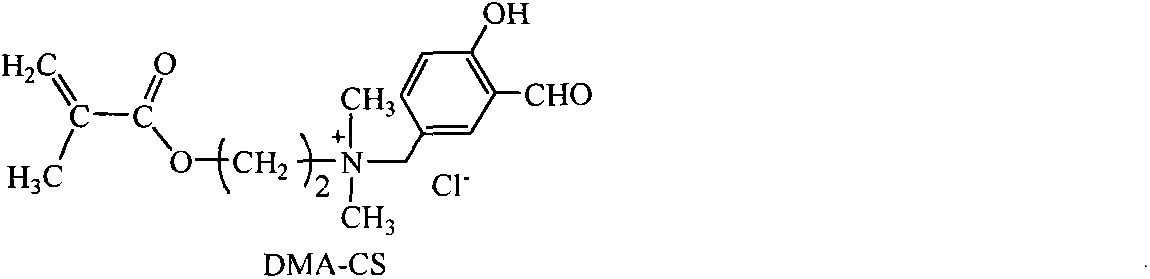

[0035] The preparation of embodiment 1DMA-CS-Salen-Zn type functional monomer

[0036] Step 1. Preparation of DMA-CS

[0037]

[0038] Take by weighing -2-(dimethylamino) ethyl methacrylate (DMA) 78 grams and 5-chloromethyl salicylaldehyde (5-CS) 80 grams and dissolve in 100 grams of ethyl acetate respectively, make described The ethyl acetate solution of -2-(dimethylamino)ethyl methacrylate and the ethyl acetate solution of 5-chloromethyl salicylaldehyde, at room temperature, the ethyl acetate solution of 5-chloromethyl salicylaldehyde The solution was added into the ethyl acetate solution of 2-(dimethylamino)ethyl methacrylate, and after stirring and reacting for 4 hours, the temperature was raised to 60-65° C. and the stirring reaction was continued for 6 hours. The reaction system was left to cool to room temperature naturally, filtered to obtain a light white crystalline substance, recrystallized, and dried to obtain 151 g of DMA-CS with a yield of 95.6% and a melting...

Embodiment 2D

[0048] The preparation of embodiment 2DMA-CS-Salophen-Cu type functional monomer

[0049]

[0050] According to the method and operation steps of Example 1, the ethylenediamine in step 2 of Example 1 was replaced with o-phenylenediamine, and the zinc chloride in step 3 was replaced with copper chloride to obtain yellow-green DMA-CS- Salophen-Cu type functional monomer.

Embodiment 3

[0051] The preparation of embodiment 3DMAA-CS-Salen-Mn functional monomer

[0052] According to the method and operation steps of Example 1, the 2-(dimethylamino)ethyl methacrylate (DMA) in the first step of Example 1 was replaced with methacryloyl (2-dimethylaminoethylamine) (DMAA) , the ethylenediamine in step 2 of Example 1 is replaced by o-phenylenediamine, and the zinc chloride in step 3 is replaced by 4-vinylpyridine and manganese acetate to obtain dark red DMAA-CS-Salen-Mn functional monomer .

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com