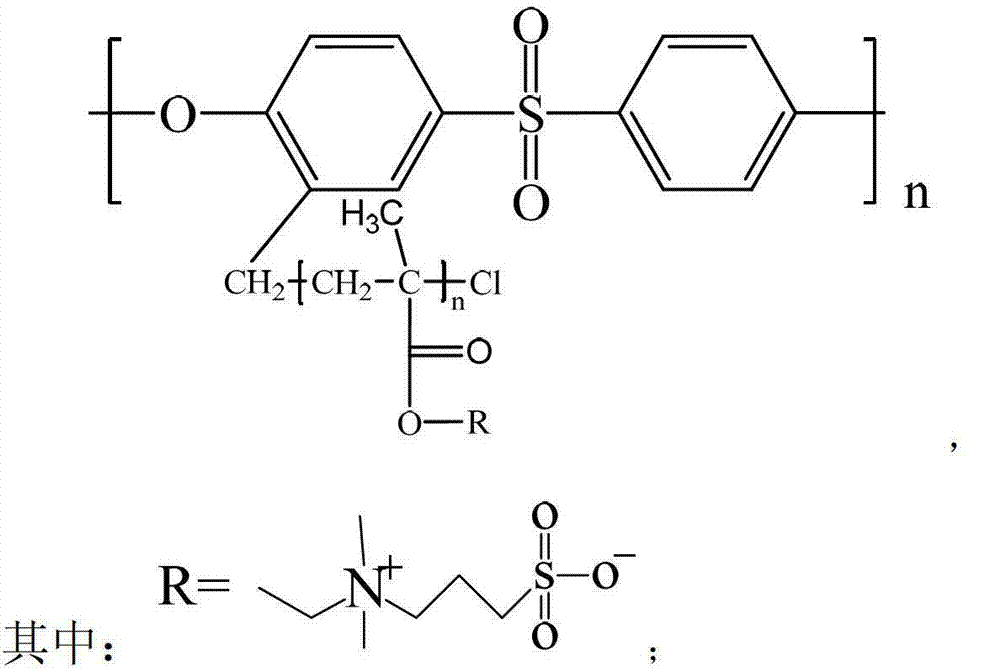

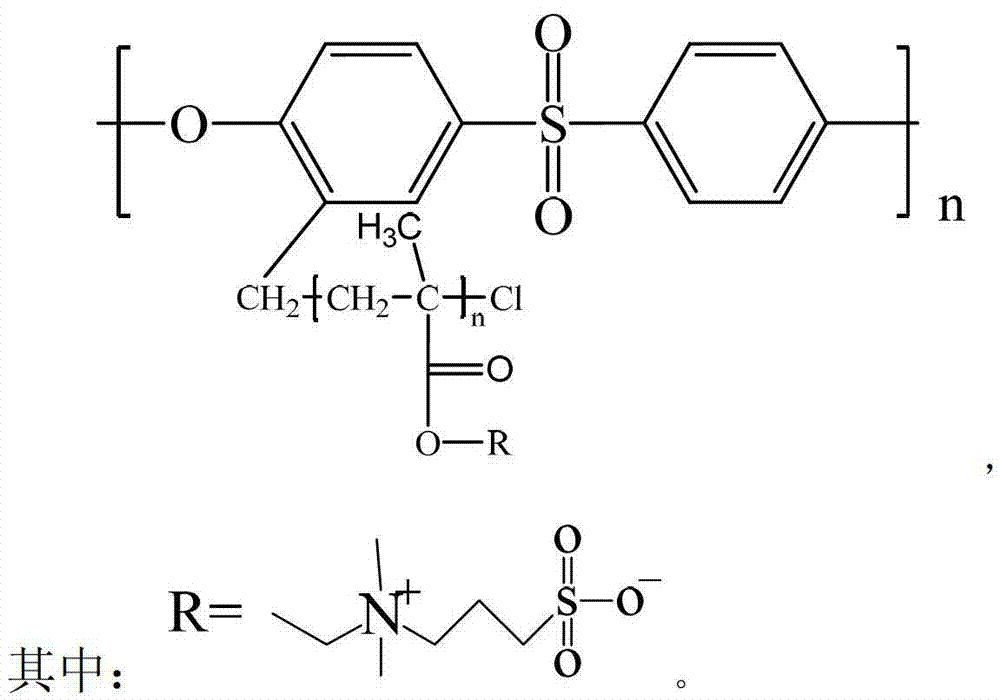

Polyether sulfone copolymer modified by sulphobetaine metacrylic acid ester as well as preparation method and application of polyether sulfone copolymer

A technology of alkali methacrylate and chloromethyl polyether sulfone is applied in the field of preparation of anti-fouling membranes, which can solve the problems of difficult modification reaction and the preparation of SBMA modified polyether sulfone, and achieve excellent anti-protein and The effect of platelets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Add 0.36g CMPES to 10ml DMSO, stir and dissolve for 12 hours, add 1.8g SBMA, stir and dissolve for 2 hours, blow nitrogen for 5 hours to remove oxygen, add 18mg CuCl and 72mg BPy, react at 70°C for 5 hours, stop nitrogen flow to terminate reaction to obtain a DMSO solution containing the SBMA-g-PES product. The elemental analysis and detection of SBMA-g-PES showed that the nitrogen content was 3.26%, and the converted grafting rate was 83%.

Embodiment 2

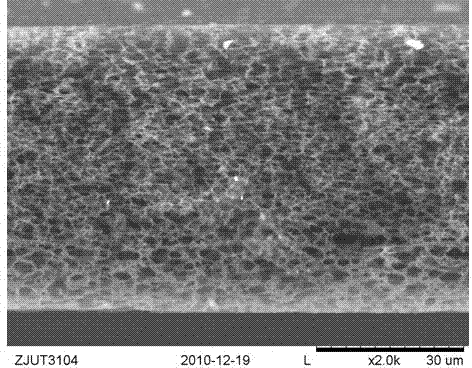

[0049] Dissolve 3.6 g of SBMA-PSU (83% grafting rate) and 3.6 g of PES in 40 mL of NMP, stir for 12 hours, and remove air bubbles. Scrape the film on the glass plate with a spatula, and immerse it in the coagulation bath of NMP:pure water=6:4 to obtain the SBMA-modified PES flat film. The resulting flat membrane thickness is about 70 μm, the average membrane pore size is 3.82 μm, and the albumin rejection rate is 5%. Its structure is as figure 1 shown.

Embodiment 3

[0051] Dissolve 0.36 g of SBMA-PSU (grafting rate of 158%) and 3.6 g of PES in 20 mL of NMP, stir for 12 hours, and remove air bubbles. The film was scraped off on a glass plate with a spatula, and immersed in a pure water coagulation bath to obtain a SBMA-modified PES flat film. The resulting flat membrane thickness is about 50 μm, the average membrane pore size is 0.27 μm, and the albumin rejection rate is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com