Method for preparing scandium oxide by using rough scandium extracted from waste acid water of titanium dioxide as raw material

A technology of titanium dioxide waste acid and water extraction, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of waste of resources, large economic losses, low recovery rate, etc., to reduce the loss and cost of scandium Low, the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

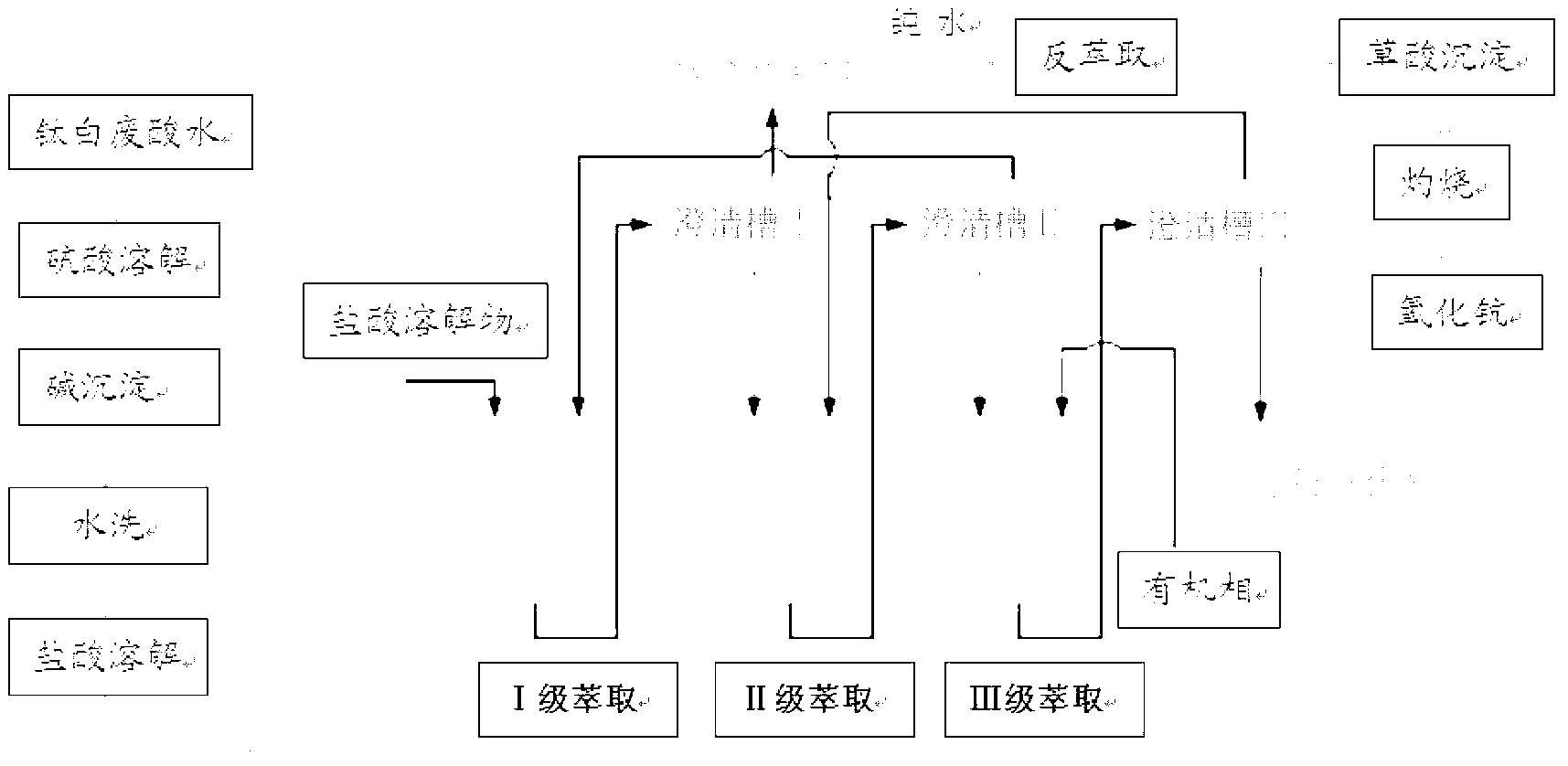

Method used

Image

Examples

Embodiment 1

[0042] 1) Sulfuric acid dissolution: 10 kg of crude scandium hydroxide extracted from titanium white waste acid water was used as raw material, and sulfuric acid was added to adjust the pH value of the mixture to 0.5; the solid-to-liquid ratio of the mixture was 1:3 (g / mL); Among them, the use of sulfuric acid has a better effect than the use of hydrochloric acid in the prior art. Specifically, the use of sulfuric acid in this link has a high dissolution rate of scandium, good filtration effect and sulfuric acid is not as volatile as hydrochloric acid, which is conducive to maintaining a better working environment. ;

[0043] 2) Alkali precipitation: the above mixture is separated by pressure filtration, sodium hydroxide is added to the obtained liquid until the pH is 11, precipitation occurs and some impurities easily soluble in strong alkali such as aluminum and silicon are removed, and the product has high purity;

[0044] 3) Hydrochloric acid dissolution: step 2) the obtai...

Embodiment 2

[0051] 1) Sulfuric acid dissolution: 10 kg of crude scandium hydroxide extracted from titanium white waste acid water was used as raw material, and sulfuric acid was added to adjust the pH value of the mixture to 0.1; the solid-to-liquid ratio of the mixture was 1:3 (g / mL);

[0052] 2) Alkali precipitation: the above mixture is separated by pressure filtration, sodium hydroxide is added to the obtained liquid until the pH is 11, precipitation occurs and some impurities easily soluble in strong alkali such as aluminum and silicon are removed, and the product has high purity;

[0053] 3) Hydrochloric acid dissolution: step 2) the obtained precipitate is first washed with water until the pH of the washing solution is 7, and then dissolved with hydrochloric acid to obtain a hydrochloric acid soluble matter until the pH is 0.5;

[0054] 4) Extraction: add dimethyl heptyl phosphate and diesel oil as the organic phase in the hydrochloric acid soluble matter, the volume ratio of the me...

Embodiment 3

[0060] 1) Sulfuric acid dissolution: 10 kg of crude scandium hydroxide extracted from titanium white waste acid water was used as raw material, and sulfuric acid was added to adjust the pH value of the mixture to 0.1; the solid-to-liquid ratio of the mixture was 1:3 (g / mL);

[0061] 2) Alkali precipitation: the above mixture is separated by pressure filtration, sodium hydroxide is added to the obtained liquid until the pH is 11, precipitation occurs and some impurities easily soluble in strong alkali such as aluminum and silicon are removed, and the product has high purity;

[0062] 3) Hydrochloric acid dissolution: step 2) the obtained precipitate is first washed with water until the pH of the washing solution is 7 and then dissolved with hydrochloric acid to obtain a hydrochloric acid soluble matter until the pH is 1.0;

[0063] 4) Extraction: Add dimethylheptyl phosphate and kerosene as the organic phase in the hydrochloric acid soluble matter, the volume ratio of the methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com