Method and device for purifying molybdenum concentrate

A purification method and molybdenum concentrate technology, applied in the field of molybdenum concentrate purification method and device, can solve the problems affecting sales price and market competitiveness, low content of iron impurity components, cumbersome charging process, etc., to reduce manpower and material resources The effects of investment and operating time, simplified process, and reasonable equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Raw material: molybdenum concentrate, see Table 1 for chemical composition.

[0052] Table 1 Chemical composition of molybdenum concentrate (wt%)

[0053] Mo SiO 2 As sn P Cu Pb CaO Fe Oil and water 47 11.0 0.06 0.05 0.04 0.26 0.31 2.50 0.95 5.42

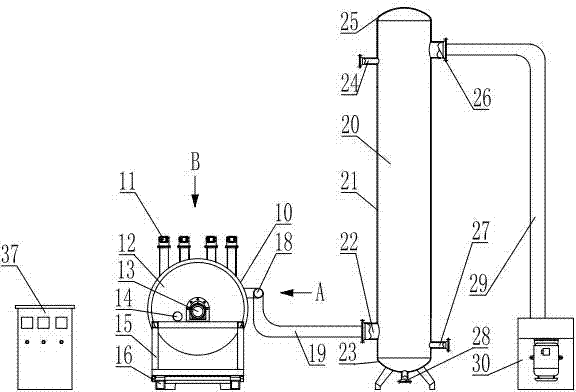

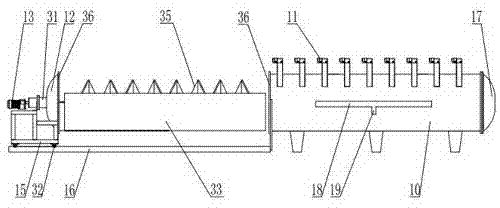

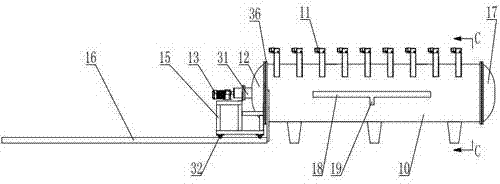

[0054] Equipment: the overall structure is as follows figure 1 , the diameter of the heating furnace body is 1.8m, the length is 6.2m, the length of the silo is 6m, and there are 4 groups of microwave generators with a total power of 72KW. There are observation windows on the front and rear doors of the heating furnace, and the electrical control system is located in In the electrical cabinet, microwave heating is controlled, and the front door and silo of the heating furnace are separated or combined with the heating furnace body; the heat exchange system uses circulating water as the heat exchange medium.

[0055] use figure 1 The specific production process of the shown purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com