Manufacturing method of low-temperature ferrite nodular cast iron material

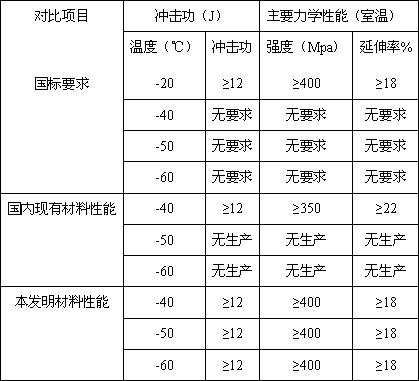

A technology of ductile cast iron and its manufacturing method, which is applied in the manufacturing field of new low-temperature, high-strength, high-toughness and impact-resistant ferritic ductile iron materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

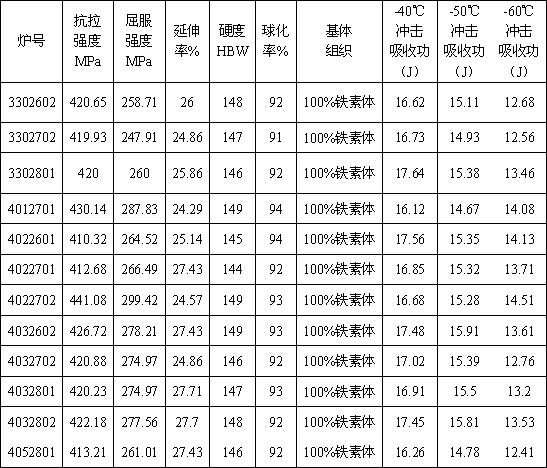

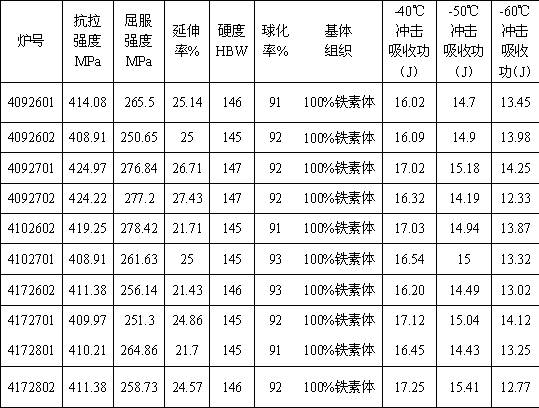

Examples

Embodiment Construction

[0055] The present invention will be further described below in combination with specific embodiments.

[0056] The methods used in the following examples are conventional methods unless otherwise specified, and the percentages are mass percentages unless otherwise specified.

[0057] (1), Raw material feeding mass ratio: scrap steel 10%, returned furnace iron 10%, high-purity pig iron (C≥3.5%; Si≤0.5%; Mn≤0.2%; P≤0.03%; S≤0.02%; Ti≤0.03 %; other trace elements: the total content of chromium, molybdenum, vanadium, tin, antimony, lead, bismuth, aluminum, boron, tellurium, arsenic, etc. ≤ 0.05%.) 80%; and scrap steel, returned iron, high-purity pig iron total Amount of 0.8% nickel.

[0058] (2) Smelting: The furnace temperature is 1540-1550°C;

[0059] (3) The process of feeding spheroidization and inoculation treatment is adopted; the process of monofilament feeding spheroidization and furnace inoculation treatment is adopted; the process of subcontracting spheroidization is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com