Preparation method of cadmium telluride thin-film solar cell and graphite conductive paste used by preparation method

A technology for solar cells and conductive paste, which is applied in the directions of carbon silicon compound conductors, circuits, electrical components, etc., can solve the problems of high cost of cadmium telluride thin film solar cells, high material prices, and high equipment costs, and is beneficial to large-scale industries. chemistry, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A preparation method of cadmium telluride thin film solar cell and graphite conductive paste used therein

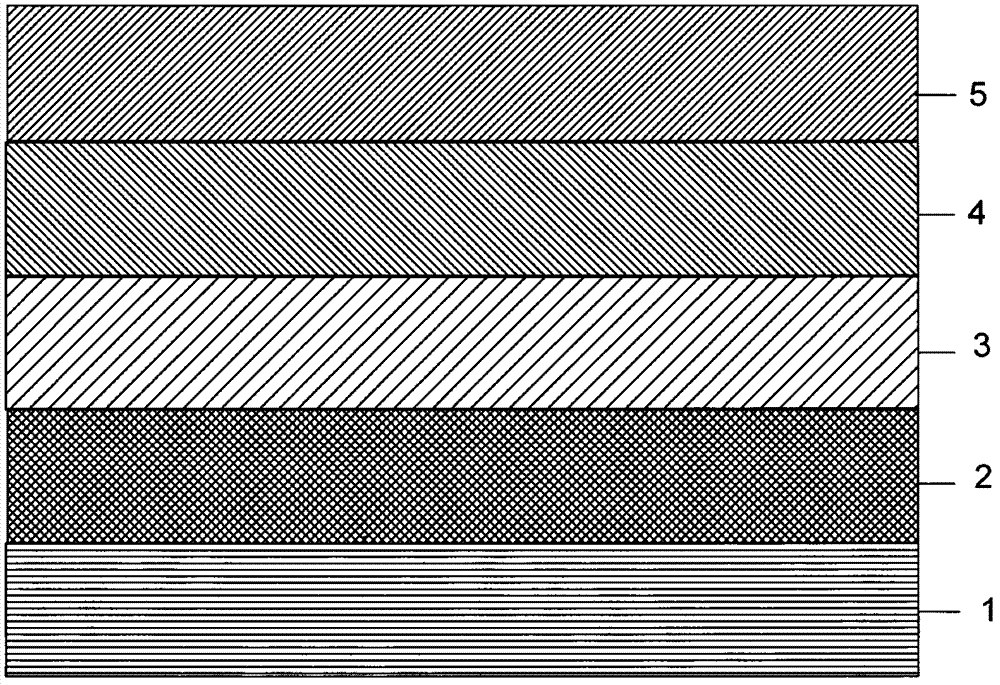

[0038] The cadmium telluride thin film solar cell structure that the present invention makes is as follows figure 1 shown in the attached figure 1 In , the thicknesses of layers and regions are exaggerated for clarity. Also, the illustrated thickness ratios between the layers do not actually reflect the thickness ratios of the layers in the solar cell. The cadmium telluride thin film solar cell is composed of a transparent conductive film 1, a window layer 2, a CdTe absorbing layer 3, a conductive back contact layer 4 made of graphene and graphite, and a metal back electrode layer 5.

[0039]Similar to the conventional CdTe thin film solar cell, the CdTe thin film solar cell of the present invention also includes a transparent conductive film 1, a window layer 2 and a CdTe absorber layer 3, and the window layer 2 and the CdTe absorber layer 3 are u...

Embodiment 2

[0052] Embodiment 2, a kind of preparation method of cadmium telluride thin-film solar cell and graphite conductive paste used therefor

[0053] A method for preparing a cadmium telluride thin-film solar cell, comprising forming a cadmium telluride layer, covering one side of the cadmium telluride layer with a graphite conductive paste with a thickness of 2 microns, drying it in an annealing furnace at a temperature of 260°C Heat treatment under conditions for 40 minutes; wherein, the graphite conductive paste is composed of the following materials in mass percentage:

[0054] Base material 90%;

[0055] Graphene 10%;

[0056] The base material is carbon black; the particle size of the base material is 0.005-0.9 microns; the graphene is a single-layer graphene. In this embodiment, except for the back contact layer 4 , the preparation method of other parts is the same as that in Embodiment 1, and a known preparation method can also be used. In this embodiment, since no dispe...

Embodiment 3

[0057] Embodiment 3, a preparation method of cadmium telluride thin film solar cell and graphite conductive paste used therefor

[0058] A method for preparing a cadmium telluride thin-film solar cell, comprising forming a cadmium telluride layer, covering one side of the cadmium telluride layer with a graphite conductive paste with a thickness of 1 micron, drying it in an annealing furnace at a temperature of 240°C Heat treatment 50 minutes under condition; Wherein, the formula of described graphite conductive paste is shown in Table 1:

[0059] The base material is graphite; the particle size of the base material is 0.5-0.7 microns; the graphene is single-layer graphene. In this embodiment, except for the back contact layer 4 , the preparation method of other parts is the same as that in Embodiment 1, and a known preparation method can also be used.

[0060] Table 1: Formulation of graphite conductive paste

[0061]

[0062] Note: basic material: embodiment four ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com