Technology for efficiently removing NOx pollutants in smoke

A flue gas and process technology, which is applied in the field of oxidation and absorption process, can solve the problems of large difference and achieve the effect of low operating cost, high oxidation absorption effect and easy source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

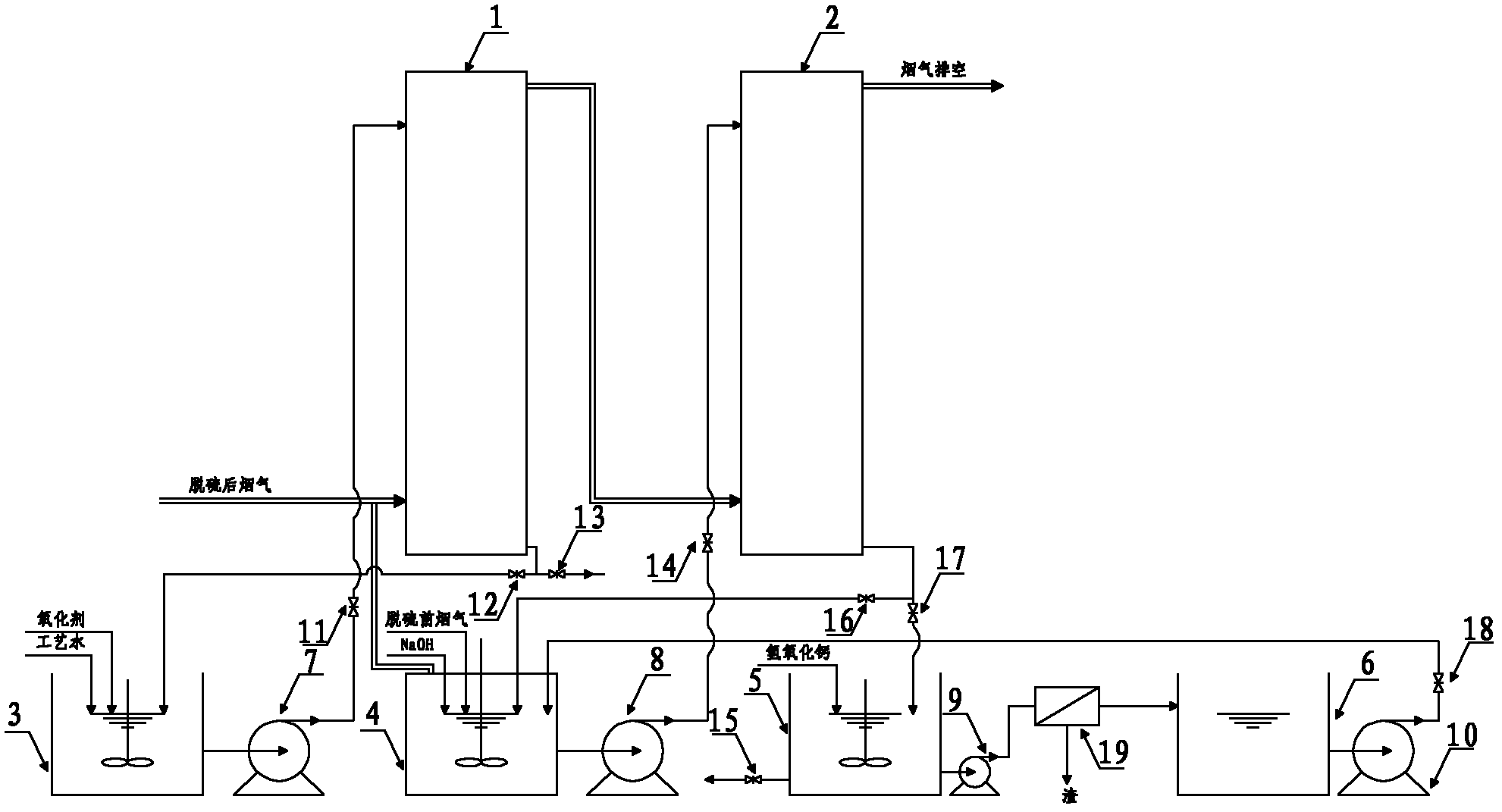

Method used

Image

Examples

example 1

[0019] Example 1: Under the intake conditions of about 90% nitrogen and about 10% oxygen, using sodium chlorite with a mass concentration of 1% as an oxidant and sodium sulfite with a mass concentration of 10% as an absorbent, the measured NO X The concentration was reduced from 57ppm to 12ppm, and the denitrification efficiency was 78.9%.

example 2

[0020] Example 2: The reaction of calcium hydroxide with a mass concentration of 3.35% and sodium sulfate with a mass concentration of 6.5% is used to regenerate sodium hydroxide and filter. Feed SO containing 4000ppm into the filtrate 2 The gas, adjust the pH of the solution to 7-8, at this moment the mass concentration of sodium sulfite in the solution is about 3%. Take this solution as absorbent, and sodium chlorite with a mass concentration of 1% is used as oxidant, and two sets of data are measured under the inlet conditions of about 90% nitrogen and about 10% oxygen: imported NO X From 55ppm to 11ppm at the outlet, the denitrification efficiency is 80.0%.

[0021] From the above examples, it can be seen that the denitrification efficiency of this process is very high, the regeneration effect of sodium hydroxide is better, and the absorption efficiency of the absorbent generated by the regenerated sodium hydroxide is almost not reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Denitrification efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com