High-strength environmental-friendly high-efficiency water reducing admixture and preparation method thereof

A technology of water reducing agent and naphthalene series water reducing agent, which is applied in the preparation of high-strength environmental protection and high-efficiency water-reducing agent, and the field of high-strength environmental protection and high-efficiency water-reducing agent, can solve the problems of high dosage, reduce the growth rate of early strength of concrete, etc. The degree of hydration, superior economy and environmental protection, the effect of reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

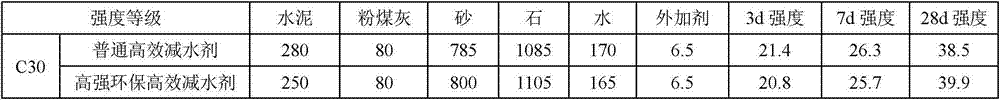

Embodiment 1

[0039] 536 grams of industrial naphthalene (purity is 95%, the same below) is completely melted, and sulfonation reaction is carried out with 574 grams of 98% concentrated sulfuric acid, the temperature is controlled at 160 degrees, the heat preservation reaction is 2 hours, then cooled to 110 degrees, and 222 grams of water are added And stir for hydrolysis, control the acidity value after hydrolysis at about 25.0%, then add 314 grams of 37% formaldehyde dropwise for condensation reaction, control the temperature at 115 degrees and condense for 4.5 hours at an air pressure of 0.05-0.25 MPa, cool down, and then add 960 grams of 30 % concentration of sodium hydroxide for neutralization reaction, adjust the pH value between 8 and 9, and finally add 240 grams of concrete strengthening component sodium fluorosilicate, 45 grams of retarding component sodium gluconate, and 8 grams of rosin soap air-entraining agent , and water (quantity to control the total solid content at about 35%...

Embodiment 2

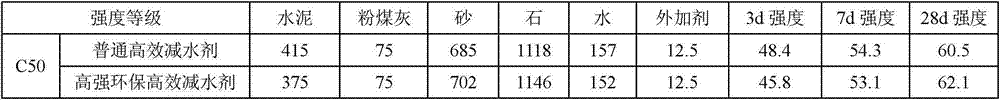

[0047] Completely melt 536 grams of naphthalene, carry out sulfonation reaction with 595 grams of concentrated sulfuric acid, control the temperature at 165 degrees, heat preservation reaction for 3 hours, then cool down to 110 degrees, add 222 grams of water and stir for hydrolysis, control the acidity value after hydrolysis at 27.5 %, then add 310 grams of formaldehyde dropwise for condensation reaction, control the temperature at 105 degrees and condense for 4.5 hours at an air pressure of 0.05 to 0.25 MPa, cool down, then add 980 grams of 30% sodium hydroxide for neutralization reaction, and adjust the pH value Between 7 and 8, finally add 320 grams of concrete reinforcement component triethanolamine, 25 grams of retarding component sodium citrate, 5 grams of rosin soap air-entraining agent, and water (quantity to control the total solid content at about 35%) , that is, the required high-strength, environment-friendly and high-efficiency water reducer.

[0048] Embodiment ...

Embodiment 3

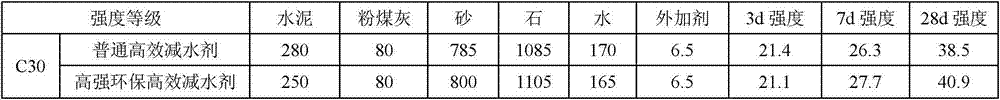

[0054] 536 grams of industrial naphthalene (purity is 95%, the same below) is completely melted, and sulfonation reaction is carried out with 585 grams of 98% concentrated sulfuric acid, the temperature is controlled at 165 degrees, and the heat preservation reaction is carried out for 2 hours, then cooled to 110 degrees, and 222 grams of water are added And stir for hydrolysis, control the acidity value after hydrolysis at about 26.0%, then add 314 grams of 37% formaldehyde dropwise for condensation reaction, control the temperature at 100 degrees and condense for 4.5 hours at an air pressure of 0.05-0.25 MPa, cool down, and then add 970 grams of 30 % concentration of sodium hydroxide for neutralization reaction, adjust the pH value between 8 and 9, and finally add 190 grams of concrete strengthening component sodium fluorosilicate, 45 grams of retarding component sodium gluconate, and rosin soap air-entraining agent 8 grams , and triisopropanolamine by 6 grams, 50 grams of fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com