Composite soft material and manufacturing method thereof

A production method and soft material technology, applied in the field of composite soft material and its production, can solve the problems of no flame retardant performance, low closed cell rate, waterproof and impermeability can not achieve waterproof and impermeability, and achieve high waterproof and impermeable performance. , the preparation method is simple, the effect of excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

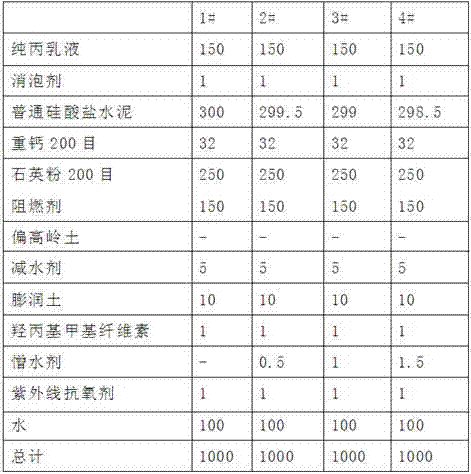

[0022] The following formulations do not add metakaolin, but use different water-repellent additions for comparison.

[0023] (1) Formula

[0024]

[0025] (2) Performance test

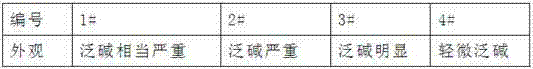

[0026] A. Observation of ubiquinolone

[0027] Mix the components of the above 1#, 2#, 3#, 4# formulations evenly, and spread them evenly on the exterior wall panels to form a coating; observe outdoors for one year, and the efflorescence situation is as follows:

[0028]

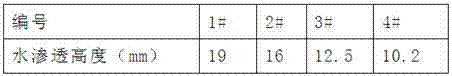

[0029] B. Impermeability test

[0030] The impermeability test is carried out according to the test method of GBJ82-85 ordinary concrete long-term performance and durability performance. The HS40WA numerically controlled permeameter was used for experiments, and the maximum working pressure was 4.0 MPa. The boosting method used in the experiment is: increasing the pressure by 0.1 MVa every 2 hours, the initial pressure is 0.6 MVa, and the final pressure is 3.8 MVa. After splitting the test block, measure the water seepage...

Embodiment 2

[0033] The following recipes add metakaolin and compare different amounts of metakaolin.

[0034] (1) Formula

[0035]

[0036] (2) Performance test

[0037] A. Observation of ubiquinolone

[0038] Mix the components of the above 1#, 2#, 3#, and formulas evenly, and spread them evenly on the exterior wall panels to form a coating; observe outdoors for one year, and the efflorescence conditions are as follows:

[0039]

[0040] B. Impermeability test

[0041] The impermeability test is carried out according to the test method of GBJ82-85 ordinary concrete long-term performance and durability performance. The HS40WA numerically controlled permeameter was used for experiments, and the maximum working pressure was 4.0 MPa. The boosting method used in the experiment is: increasing the pressure by 0.1 MVa every 2 hours, the initial pressure is 0.6 MVa, and the final pressure is 3.8 MVa. After splitting the test block, measure the water seepage height of each test block. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com