Production method for extracting pyrethrin from pyrethrum flower

A technology of pyrethrum and pyrethrin, which is applied in the field of pyrethrin preparation, can solve the problems of low product activity, high solvent consumption, and high production cost, and achieve huge economic and social benefits, no environmental pollution, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

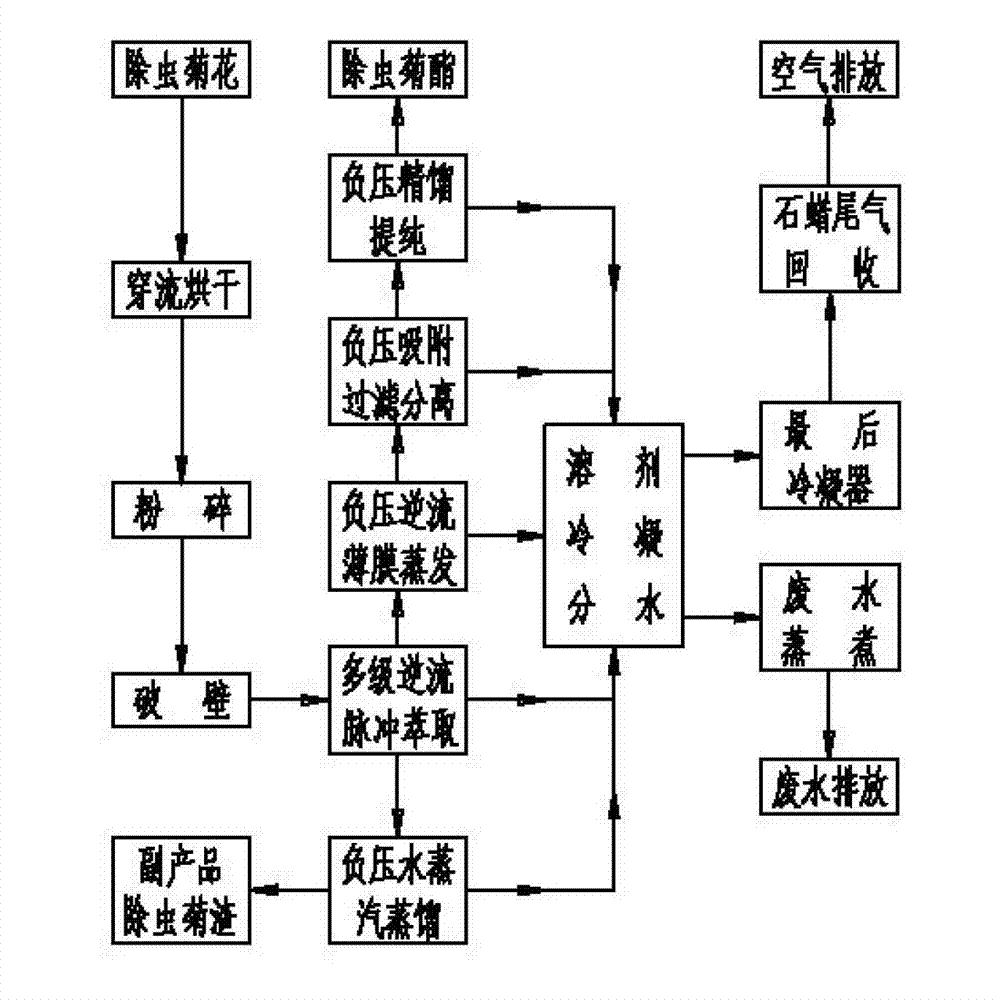

Image

Examples

Embodiment 1

[0047] (a) Drying, crushing and breaking the pyrethrum flowers through the flow: send the pyrethrum flowers into the through-flow belt type continuous dryer, hot air and cold air alternately pass through the pyrethrum flower material layer, the temperature of the hot air is 65 ° C, and the temperature of the cold air is 28°C, temperature of pyrethrum flowers is 42°C; grind the receptacles and pistils of the dried pyrethrum flowers into 10-20 mesh powders with a pulverizer; roll the pyrethrum powder into 0.3-0.5mm thick Embryo sheet;

[0048] (b) Multi-stage countercurrent pulse extraction: Pyrethrum flower embryo slices are transported to the extractor by a material sealing conveyor, and at 50°C, firstly, they are sprayed, soaked and extracted by n-hexane extraction solvent containing pyrethrins with a mass concentration of 2.0%, and then drained. dry, and then successively seven-stage spraying, soaking, and draining of extraction solvents containing pyrethrins with a mass con...

Embodiment 2

[0053] (a) Drying, crushing and breaking the pyrethrum flowers through the flow: send the pyrethrum flowers into the through-flow belt type continuous dryer, hot air and cold air alternately pass through the pyrethrum flower material layer, the temperature of the hot air is 70°C, and the temperature of the cold air is 30°C, the temperature of pyrethrum flowers is 45°C; the receptacles and stamens of the dried pyrethrum flowers are crushed into 10-20 mesh powders with a pulverizer; Embryo sheet;

[0054] (b) Multi-stage countercurrent pulse extraction: Pyrethrum flower embryos are transported to the extractor by the sealing conveyor, and at 45-50°C, they are first sprayed and soaked by n-hexane extraction solvent containing pyrethrins with a mass concentration of 1.5%. , drained, and then successively seven-stage spraying, soaking, and draining of extraction solvents containing pyrethrins with a mass concentration of 1.2%, 1.0%, 0.8%, 0.5%, 0.2%, and 0.1%, and repeated cycle ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com