Plasma texturing system and texturing method

A processing system and plasma wool technology, applied in the field of ion texturing processing system, can solve problems such as the quality affecting the weather resistance and durability of products, the hidden dangers of engineering installation safety and reliability, and the deterioration of the peeling strength of composite board products, etc. Achieve the effect of small self-loss, convenient operation and reduced switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

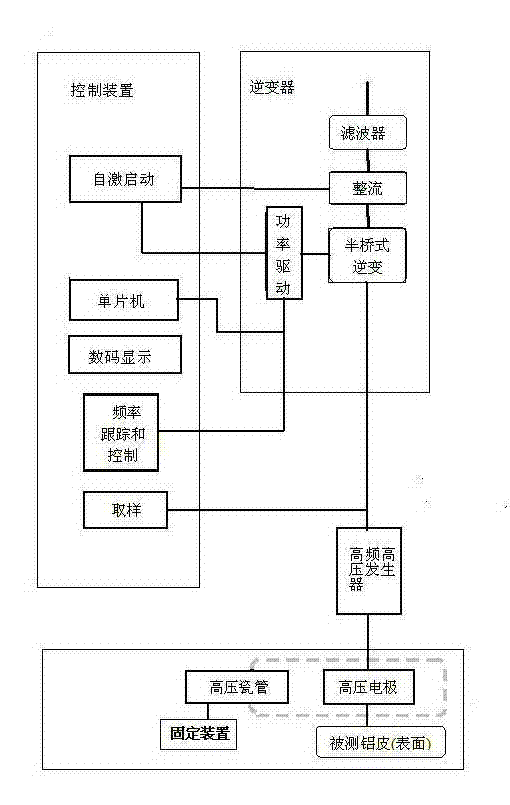

[0019] Such as figure 1 As shown, a plasma texturing system includes a plasma inverter, a control device, a high-voltage porcelain tube, a high-voltage electrode, and an aluminum profile to be tested. The plasma inverter includes a filter, a power device, and a rectifier. The control device is connected with the inverter, and the control device includes a self-excited starting circuit mode, an automatic phase-locking control mode and a single-chip microcomputer mode, and the self-exciting starting circuit mode and the automatic phase-locking control mode are used for automatic starting and tracking load resonance Frequency, the single-chip microcomputer mode is used to adjust the power in the inverter. One end of the plasma inverter is provided with a high-frequency and high-voltage generator, and the plasma inverter is connected to the high-voltage ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com