Mask plate for vapor plating

A mask and evaporation technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem of inability to reach the substrate, improve service life, improve uniformity, and avoid board surface deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

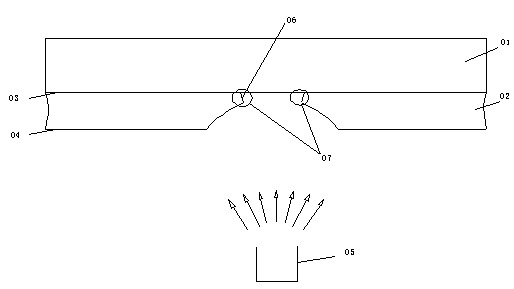

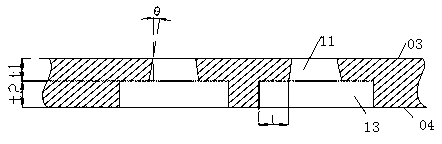

[0031] A mask plate for evaporation, which is a quadrilateral stainless steel metal plate, the mask plate has a two-layer structure of an ITO surface layer and an evaporation surface layer, and the mask plate has an opening through the ITO surface layer and the evaporation surface layer , the opening size of the ITO surface layer is smaller than the opening size of the evaporation surface layer, and the shape of the opening is an isosceles trapezoid in the transverse section along the thickness direction of the mask plate. Such as figure 2 shown.

[0032]A mask for evaporation with a thickness of 20 μm is prepared by electroforming, and it is covered with openings. The uniformity of the mask is less than 5%, the surface brightness is first-class brightness, and the lateral dimension of the opening on the ITO surface layer is 20 μm, and The dimensional accuracy is ±5μm, but the opening size increases from the ITO surface layer to the evaporation surface layer, and the opening...

Embodiment 2

[0035] A mask plate for evaporation, which is a rectangular Invar metal plate, the mask plate has a two-layer structure of an ITO surface layer and an evaporation surface layer, and the mask plate has a penetrating ITO surface layer and an evaporation surface layer. The opening of the layer, the opening size of the ITO surface layer is smaller than the opening size of the evaporation surface layer, and the shape of the opening is trapezoidal on the transverse section along the thickness direction of the mask plate.

[0036] A mask for evaporation with a thickness of 20 μm was prepared by electroforming, which is covered with openings. The uniformity of the mask is less than 5%, the surface brightness is first-class brightness, the size of the opening on the ITO surface is 10 μm, and the dimensional accuracy is in ±5μm, but the size of the opening increases from the ITO surface to the evaporation surface. Cut the opening vertically along the thickness direction of the mask to ob...

Embodiment 3

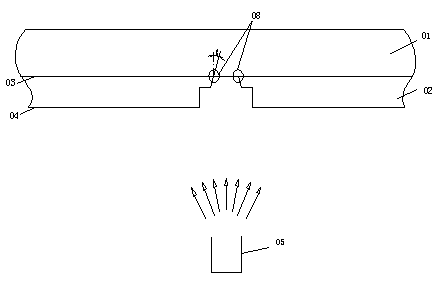

[0040] A mask for evaporation is shaped as a rectangular nickel-cobalt alloy metal plate. The mask has a two-layer structure of an ITO surface layer and an evaporation surface layer. The opening, the opening size of the ITO surface layer is smaller than the opening size of the evaporation surface layer, and the shape of the opening is trapezoidal on the transverse section along the thickness direction of the mask plate.

[0041] The thickness of the ITO surface layer is 20um, and the thickness of the evaporated surface layer is 80um. The openings on the ITO surface and the evaporation surface are connected by several solid bridges, and the openings are regularly distributed on the mask; The direction of the dimension side is transverse, and the transverse dimension of the opening on the ITO surface is smaller than the transverse dimension of the opening on the evaporation surface. The lateral dimensional accuracy of the opening on the ITO surface is ±5 μm; the vertical depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com