Method for preparing graphene nano-material electrochemical sensor by atomic layer deposition process

A technique of atomic layer deposition and material electrochemistry, applied in the direction of material electrochemical variables, gaseous chemical plating, metal material coating technology, etc., can solve problems such as expensive instruments and complex operations, and achieve low cost, simple process, The effect of keeping the cost low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

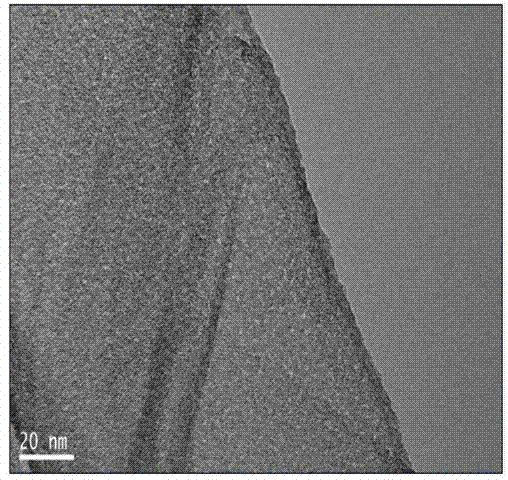

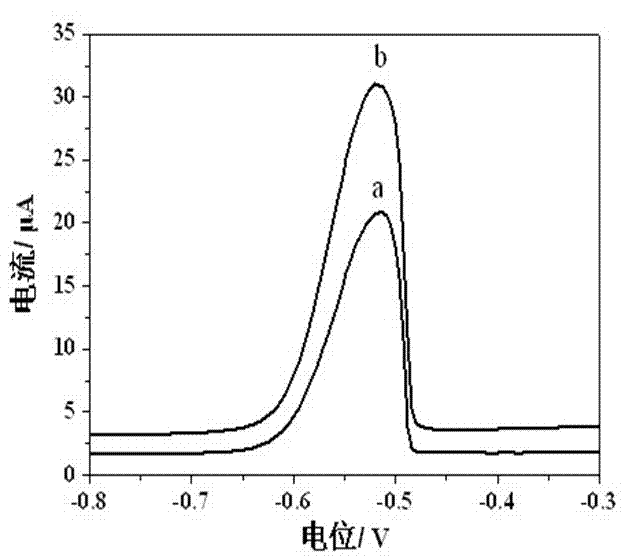

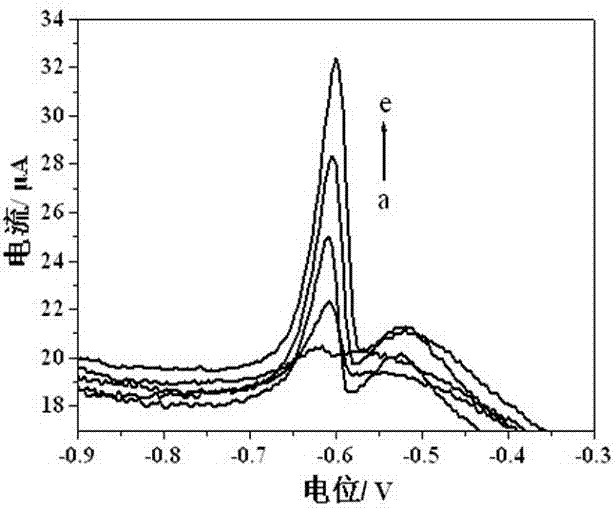

[0027] Graphite oxides were synthesized from graphite powder according to Hummer's method. The specific steps are: weigh a certain amount of graphite powder, and add an appropriate amount of K 2 S 2 o 8 ,P 2 o 5 and concentrated sulfuric acid, heated at 80 °C for 4.5 h. The mixture was then cooled to room temperature, diluted with deionized water and left overnight, washed to remove unreacted acid, and dried to obtain pre-oxidized graphite. Then put the pre-oxidized graphite into sulfuric acid, add KMnO 4 Stir, dilute with deionized water, stir and add deionized water. Then a certain concentration and a certain amount of H 2 o 2 Added to the above mixture, it can be seen that the color of the solution has become bright yellow. The resulting mixture was then filtered and washed with hydrochloric acid and deionized water to remove metal ions and residual acid, respectively. Dry to obtain graphite oxide. Then it is formulated into a solution and peeled off under the ac...

Embodiment 2

[0031] Graphite oxides were synthesized from graphite powder according to Hummer's method. The specific steps are: weigh a certain amount of graphite powder, and add an appropriate amount of K 2 S 2 o 8 ,P 2 o 5 and concentrated sulfuric acid, heated at 80 °C for 4.5 h. The mixture was then cooled to room temperature, diluted with deionized water and left overnight, washed to remove unreacted acid, and dried to obtain pre-oxidized graphite. Then put the pre-oxidized graphite into sulfuric acid, add KMnO 4 Stir, dilute with deionized water, stir and add deionized water. Then a certain concentration and a certain amount of H 2 o 2 Added to the above mixture, it can be seen that the color of the solution has become bright yellow. The resulting mixture was then filtered and washed with hydrochloric acid and deionized water to remove metal ions and residual acid, respectively. Dry to obtain graphite oxide. Then it is formulated into a solution and peeled off under the ac...

Embodiment 3

[0035] Graphite oxides were synthesized from graphite powder according to Hummer's method. The specific steps are: weigh a certain amount of graphite powder, and add an appropriate amount of K 2 S 2 o 8 ,P 2 o 5 and concentrated sulfuric acid, heated at 80 °C for 4.5 h. The mixture was then cooled to room temperature, diluted with deionized water and left overnight, washed to remove unreacted acid, and dried to obtain pre-oxidized graphite. Then put the pre-oxidized graphite into sulfuric acid, add KMnO 4 Stir, dilute with deionized water, stir and add deionized water. Then a certain concentration and a certain amount of H 2 o 2 Added to the above mixture, it can be seen that the color of the solution has become bright yellow. The resulting mixture was then filtered and washed with hydrochloric acid and deionized water to remove metal ions and residual acid, respectively. Dry to obtain graphite oxide. Then it is formulated into a solution and peeled off under the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com