A kind of LED backlight liquid crystal display device and coating method of luminescent material thereof

A technology of liquid crystal display devices and luminescent materials, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems that are not conducive to improving the color gamut of LCD display equipment, the requirements for filter performance of color filters are high, and the purity of incident light sources is low. Achieve the effects of rich display colors, improved spectral color purity, and enhanced color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

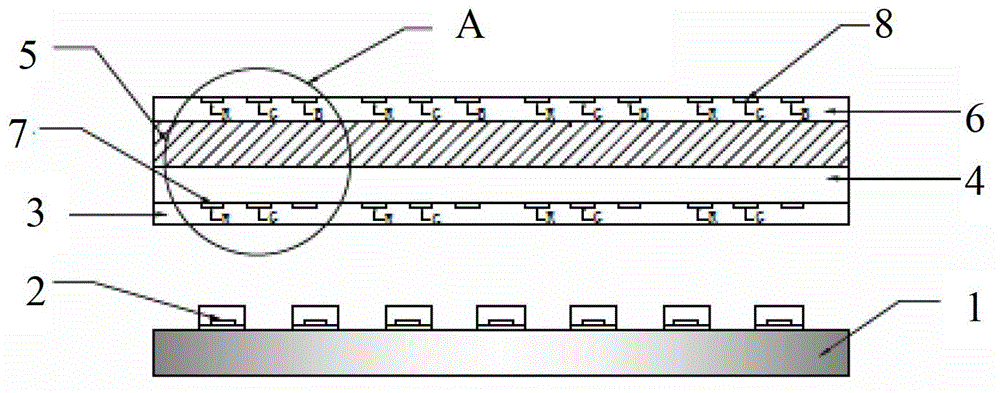

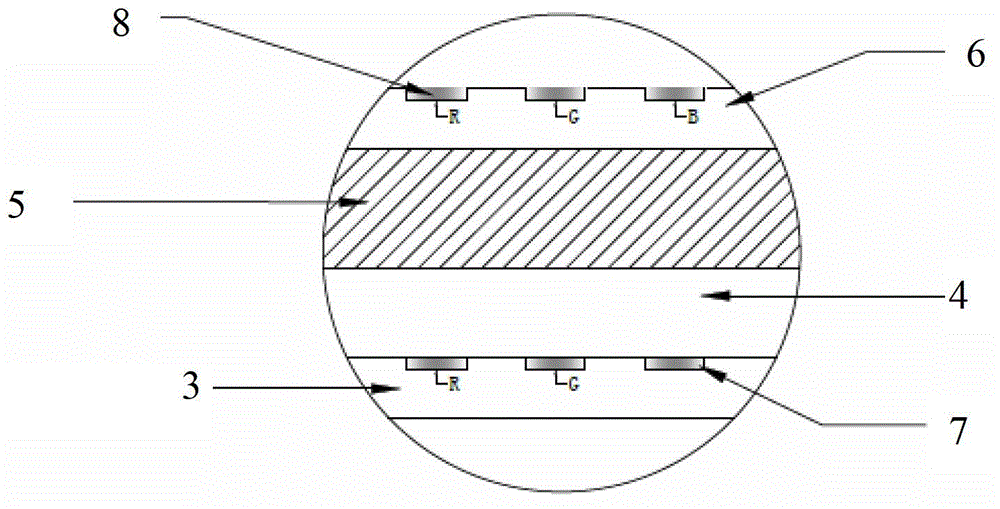

[0039] Such as figure 1 , 2 As shown, the present invention is composed of LED light source module 1, phosphor substrate 3, TFT substrate 4, liquid crystal 5 and color filter substrate 6, LED chip 2 is packaged in LED light source module 1, and red and green phosphors are coated on On an independent transparent substrate, it has the same shape and corresponding color as the RGB color filter.

[0040] The production method is as follows: 1) Encapsulation glue is used to encapsulate the blue LED chip into the bracket, and after drying, it is welded to the aluminum substrate in series to form an LED light source module; 2) The nano-phosphor is deposited by evaporation Coating on a transparent substrate to prepare a phosphor substrate; 3) Coating frame sealant around the TFT array substrate, and spreading spacers with a size of 5 to 10 m on it as support points; 4) Combining steps 2 and 3 The result is combined in sequence with the phosphor substrate, TFT array substrate and col...

Embodiment 2

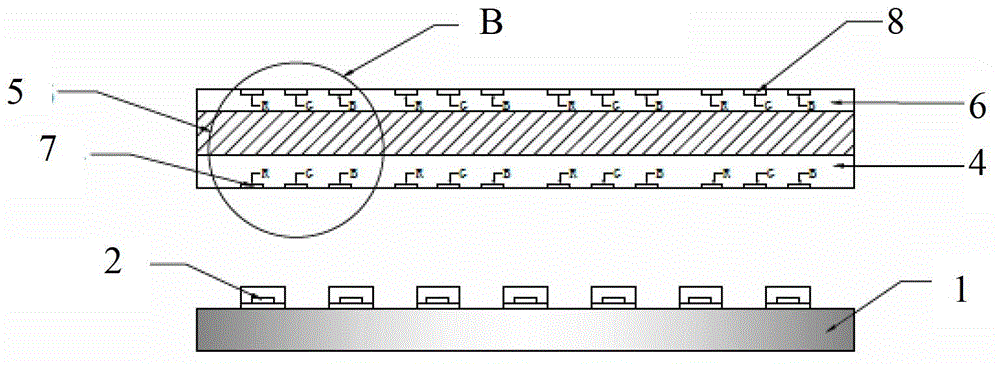

[0042] Such as image 3 As shown, the present invention is composed of an LED light source module 1, a TFT substrate 4, a liquid crystal 5 and a color filter substrate 6, an ultraviolet LED chip 2 is packaged in the LED light source module 1, RGB luminescent materials are coated on the TFT array substrate, Same shape and corresponding color as RGB color film.

[0043] The production method is as follows: 1) Encapsulate the ultraviolet LED chip into the bracket with packaging glue, and weld it to the ceramic substrate in series after drying to form an LED light source module; Powder coated on the TFT array substrate; 3) Coat the frame sealant around the TFT array substrate, and spread spacers with a size of 5-10 μm on it as support points; 4) Combine the TFT array substrate and the color filter substrate , forming an empty box between the TFT substrate and the color film substrate, injecting liquid crystal into it to obtain a liquid crystal panel; 5) combining the ultraviolet ...

Embodiment 3

[0045] Such as Figure 4 As shown, the present invention is composed of an LED light source module 1, a TFT substrate 4, a liquid crystal 5 and a color filter substrate 6. The blue LED chip 2 is packaged in the LED light source module 1, and the fluorescent powder is coated on the color filter substrate, and the RGB The color filters have the same shape and corresponding colors.

[0046] The production method is as follows: 1) Use encapsulation glue to package the blue LED chip into the bracket, and after drying, weld it to the aluminum substrate in series to form an LED light source module; 2) Use the evaporation method to combine red and green Nano phosphors are coated on the color film substrate, and the shape and position correspond to the red and green color film; 3) Coat the sealant around the TFT array substrate, and spread 5-10μm spacers on it for support Point; 4) Combine the TFT array substrate and the color film substrate, form an empty box between the TFT substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com