Solar cell manufacturing method and solar cell

A technology of solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to accurately control doping ion concentration and doping uniformity, and high manufacturing costs, and achieve cost reduction and simplification of process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

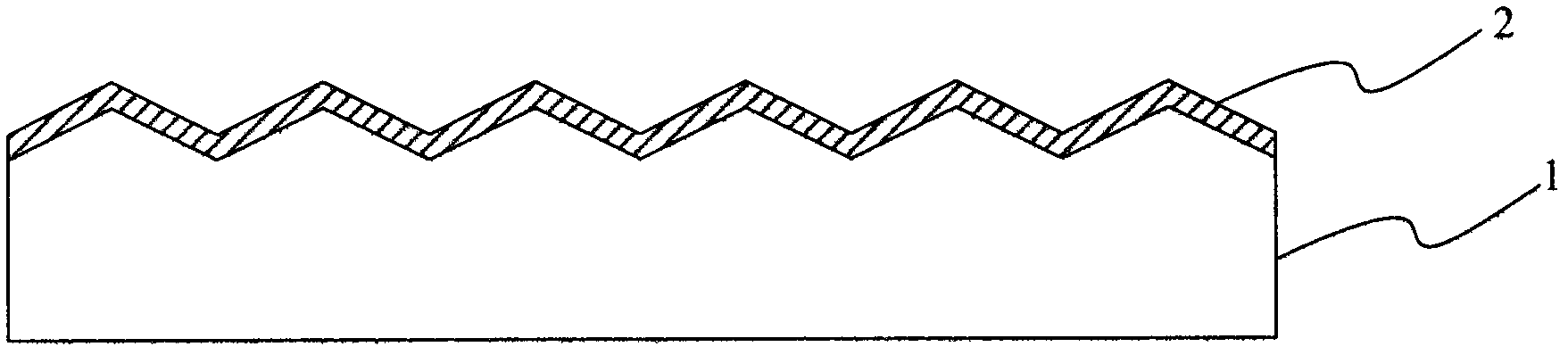

[0069] refer to figure 1 , forming a surface N+ doped layer 2 on the surface of the N-type substrate 1 , specifically, forming the surface N+ doped layer 2 by thermal diffusion. Wherein, the surface of the N-type substrate 1 is suede to increase the utilization rate of sunlight.

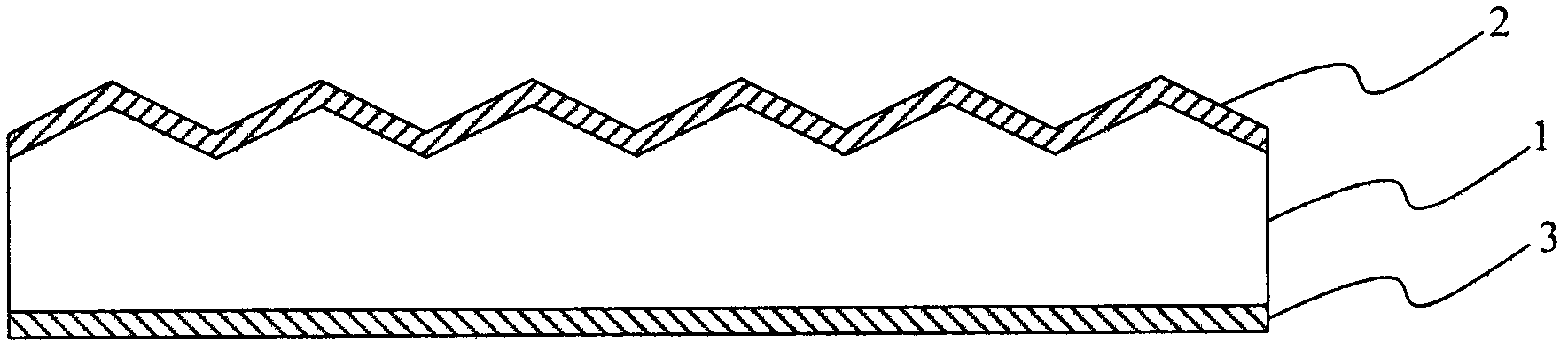

[0070] refer to figure 2 , forming an N+ doped layer 3 in the back of an N-type base 1, wherein the N+ doped layer 3 is formed by thermal diffusion. In this embodiment, BBr 3 As a diffusion source, the N+ doped layer 3 is BSG (borosilicate glass).

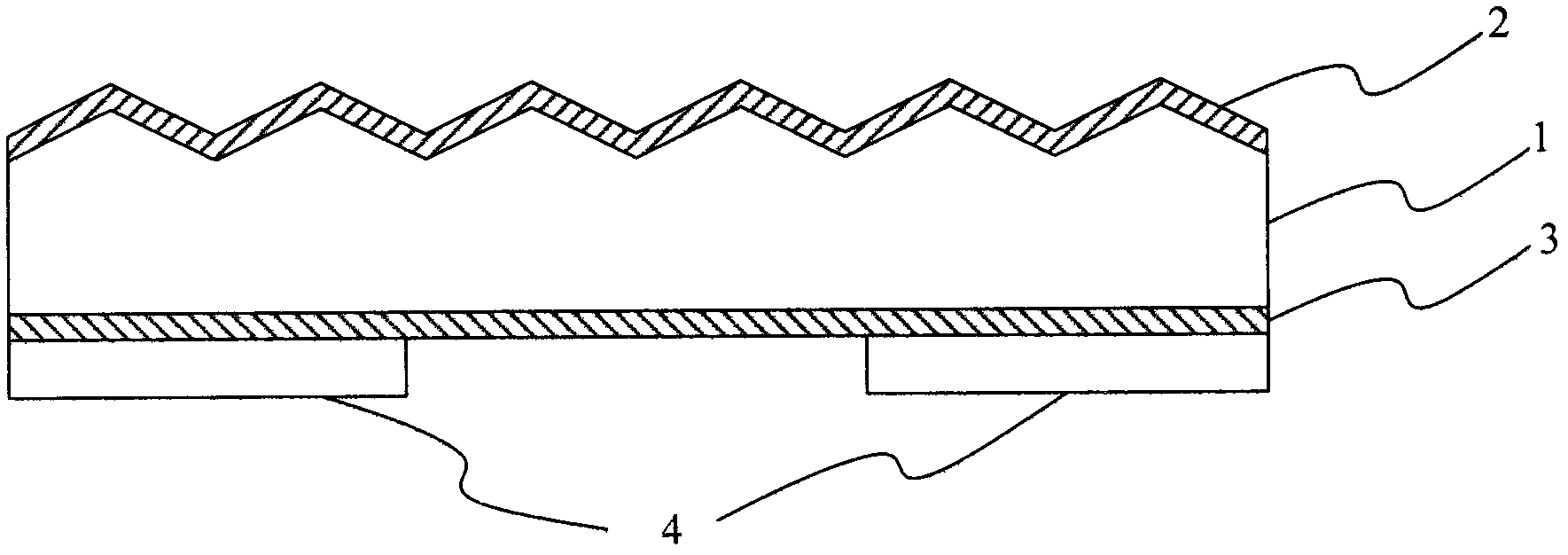

[0071] refer to image 3 A mask 4 is formed on the N+ doped layer 3 by screen printing, wherein the area not covered by the mask 4 is an open area. Wherein, the mask has a thickness of 10 μm and is made of photoresist.

[0072] refer to Figure 4 Etching the N+ doped layer 3 in the open area to the N-type substrate 1 by wet chemical method, and forming an undercut 41 in the N+ doped layer 3 above the mask 4 close to one end of the open area, where...

Embodiment 2

[0080] The principle and steps of embodiment 2 are all the same as embodiment 1, the only difference is:

[0081] refer to image 3 , the thickness of the mask is 40 μm.

[0082] refer to Figure 4 , the depth w of the formed side erosion 1 is 5 μm, and the depth of the etched N-type substrate is 3 μm.

[0083] refer to Figure 5 Accelerating boron ions to 50keV and implanting the boron ions from the open area on the surface of the N-type substrate into the N-type substrate 1 by ion implantation to form a P+ doped region 5 with a sheet resistance of 200Ω / □.

[0084] refer to Figure 9and forming a first metal layer on the second passivation layer by using metal nickel to fill the first type contact hole and the second type contact hole with the metal nickel, and sintering the first metal layer. Afterwards, a second metal layer is formed on the first metal layer by using metallic copper. In this embodiment, the stack of the first metal layer and the second metal layer is ...

Embodiment 3

[0088] The principle and steps of embodiment 3 are all the same as embodiment 1, the only difference is:

[0089] refer to Figure 4 , the depth w of the formed side erosion 1 is 3 μm, and the depth of the etched N-type substrate is three times the thickness of the N+ doped layer 3 .

[0090] refer to Figure 5 Accelerating boron ions to 30keV and implanting the boron ions from the open area on the surface of the N-type substrate into the N-type substrate 1 by ion implantation to form a P+ doped region 5 with a sheet resistance of 100Ω / □.

[0091] All the other unmentioned parts are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com