Balance control system and method for high-capacity serial connected battery packs

A series battery pack and balanced control technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as unfavorable modularization, increased difficulty in thermal management, difficult control of transformer leakage inductance, etc., to improve energy conversion efficiency , shorten the equalization time, improve the effect of equalization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

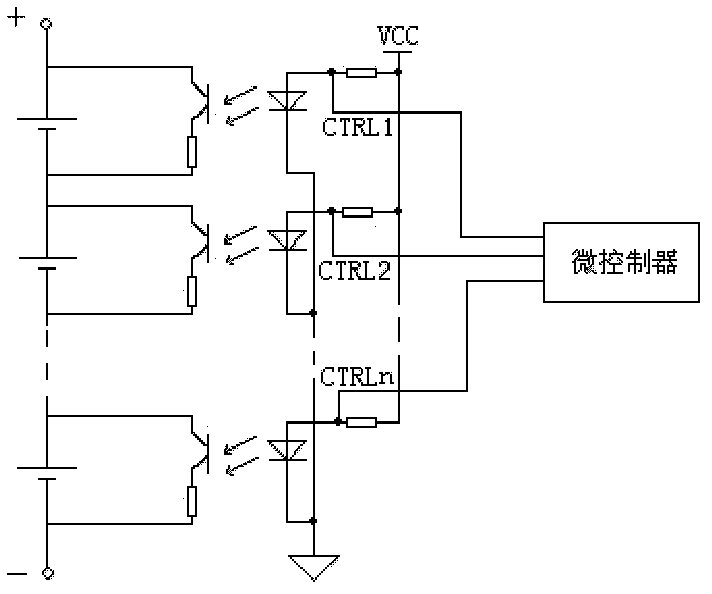

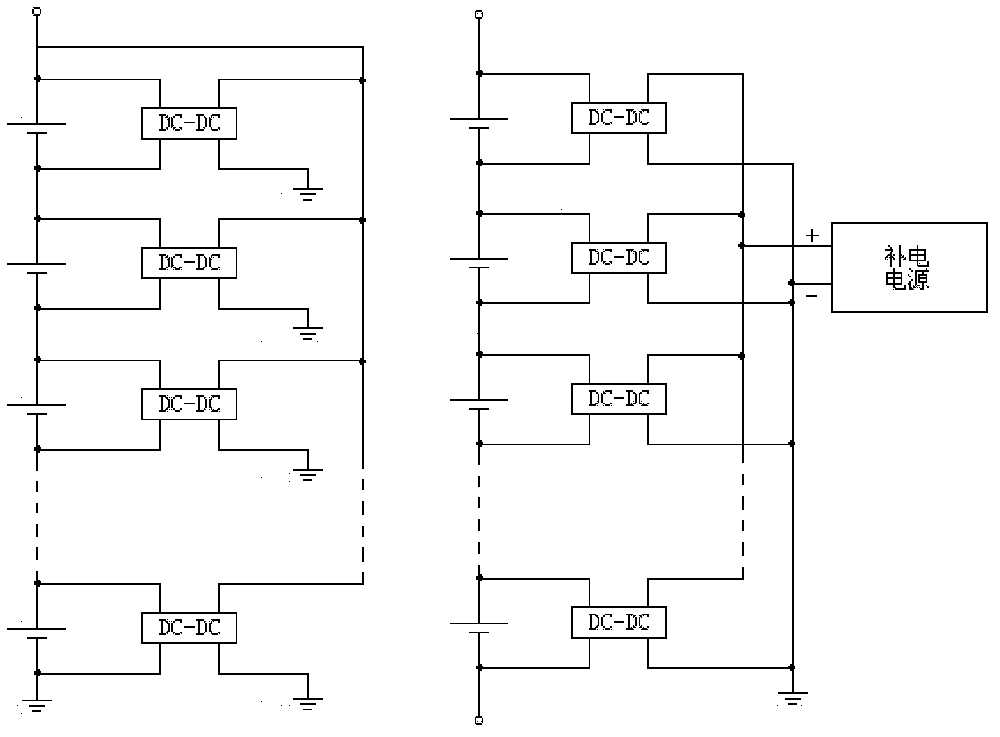

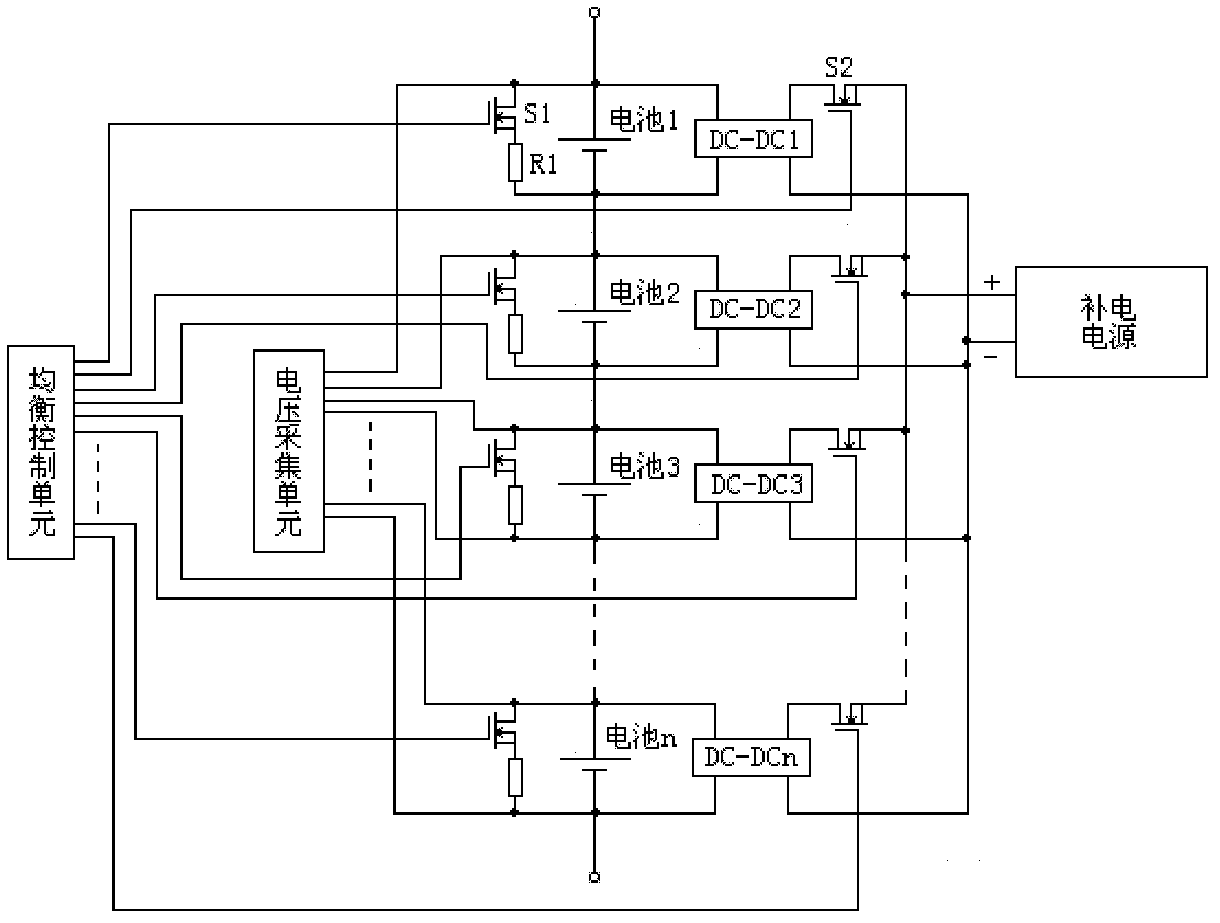

[0015] Such as image 3 As shown, a large-capacity series-connected battery pack balance control system includes a battery pack, a balance control unit, a voltage acquisition unit, a microcontroller, a power supply balance control part, and a dissipation balance control part. The power supply balance control part includes DC- DC isolated power module, power supply control switch and power supply, the input end of the DC-DC isolated power module is connected in series with the power supply control switch and connected in parallel with the power supply, the output end of the DC-DC isolated power module is connected in series with the anti-reverse diode and limiter flow resistance, and connected in parallel with each single battery in the battery pack, the power supply control switch is electrically connected with the balance control unit; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com