Textile multicomponent enhancement structure-gradually degradable ureteral stent tube and preparation method thereof

A technology for ureteral stents and reinforced structures, which is applied in stents, medical science, surgery, etc., can solve the problems of sparse structure and single weaving process, and achieve simple preparation, increased smoothness, excellent axial stretching and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

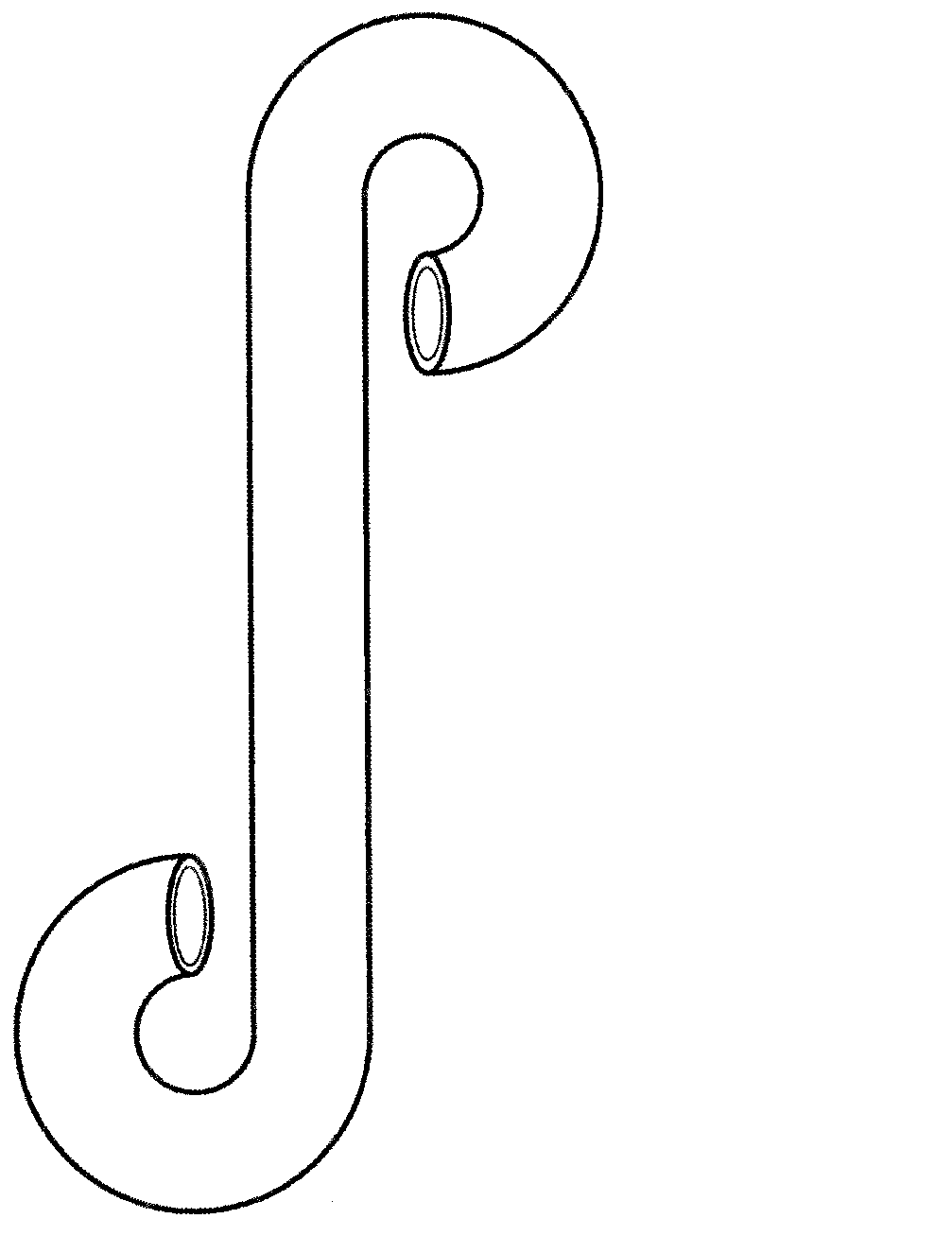

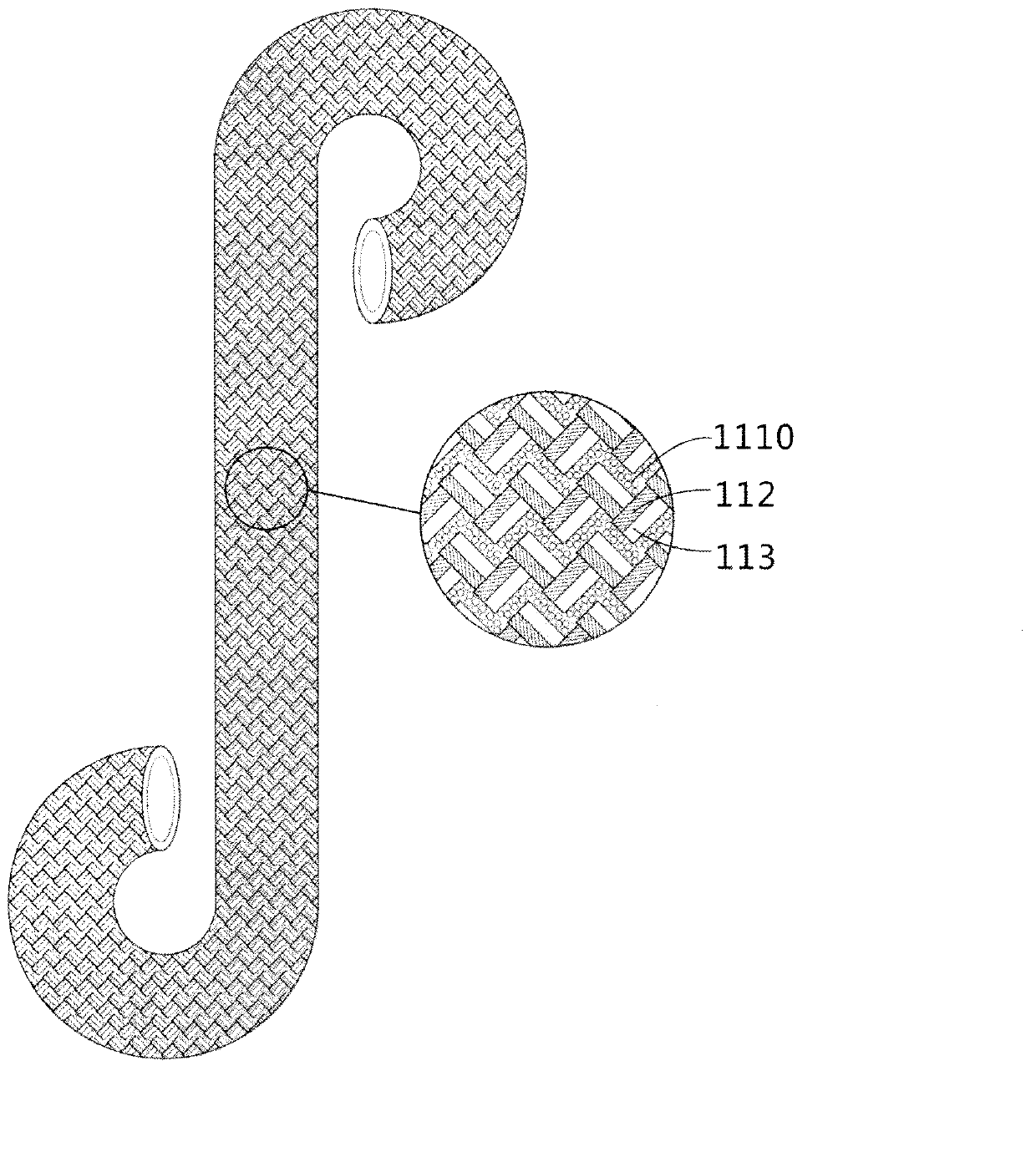

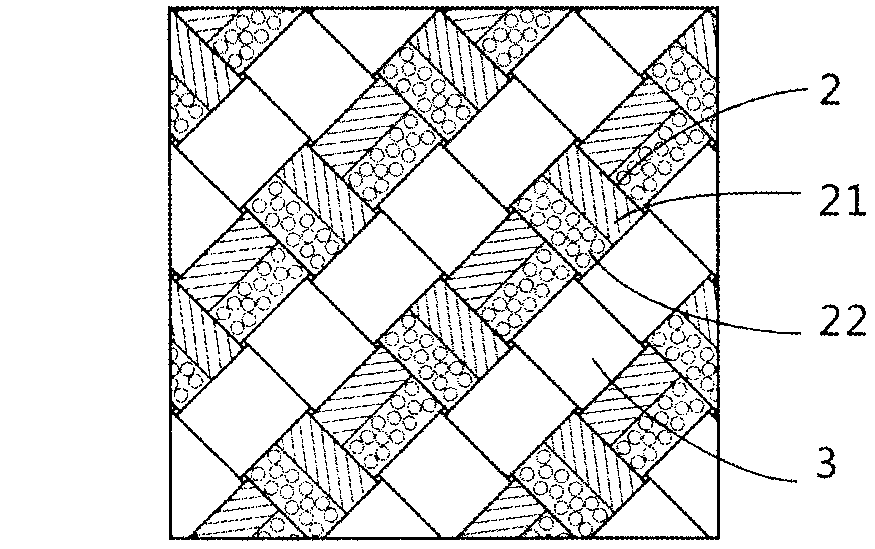

[0043] Firstly, a PLLA fiber 21 and a PDS fiber 22 are merged into yarn 2 on the doubling machine, and a PGLA fiber is yarn 3, and the two yarns of yarn 2 and yarn 3 are distributed one by one. Pour it onto the spindle of a 16-spindle braiding machine, and weave it in a diamond shape. The take-up ratio of the braiding machine is 5. The yarn is braided on a mandrel with a diameter of 0.60 mm. The total length of the braided tube is 16.0 cm. Figure 2a It is a schematic diagram of the surface of the braided structure; after the braided tube is heat-treated at 120°C for 10.0 minutes, the braided layer is removed from the mandrel to form a bracket tube; Figure 2b for Figure 2a The schematic diagram of the surface of the braided structure after heat treatment, wherein the PDS fibers 22 are fused together to become a PDS film 220 .

[0044] The obtained stent tube had an inner diameter of 0.6 mm, a total length of 16.0 cm, and a tube wall thickness of 0.085 mm. The strength when...

Embodiment 2

[0047] First, a PGLA fiber 41 and a PGA fiber 42 are combined into yarn 4 on the doubling machine, and the yarn 4 is evenly distributed and poured onto the spindles of the 24-spindle knitting machine respectively, and the regular structure is used for weaving. The ratio is 5.4, the yarn is braided on a mandrel with a diameter of 1.64mm, and the total length of the braided tube is 28.0cm. Figure 3a It is a schematic diagram of the surface of the braided structure; after the braided tube is heat-treated at 210°C for 0.3min, the braided layer is removed from the mandrel to form a stent tube; Figure 3b for Figure 3a The schematic diagram of the surface of the braided structure after heat treatment, in which the PGLA fibers 41 are fused together to become a PGLA film 410 .

[0048] The obtained stent tube had an inner diameter of 1.64 mm, a total length of 28.0 cm, and a tube wall thickness of 0.089 mm. The strength when compressing 50% of the diameter of the stent tube is 436...

Embodiment 3

[0051] First, on the doubling machine, a PGLA fiber 52 and a PDS fiber 51 are combined into a yarn 5, and then a PGA fiber 61 and a PDS fiber 51 are combined into a yarn 6, and the yarn 5 and the yarn 6 are two The yarns are poured into the spindles of the 32-spindle braiding machine according to the two-by-one distribution (two yarns 5 and one yarn 6 alternately), and the rhombus structure is used for braiding. The take-up ratio of the braiding machine is 5.8, and the yarn Braided on a mandrel with a diameter of 2.68mm, the total length of the braided tube is 40.0cm, Figure 4a It is a schematic diagram of the surface of the braided structure; after the braided tube is heat-treated at 130°C for 8.0 minutes, the braided layer is removed from the mandrel to form a bracket tube; Figure 4b for Figure 4a The schematic diagram of the surface of the braided structure after heat treatment, wherein the PDS fibers 51 are fused together to become a PDS film 510 .

[0052] The obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com