Dual-function catalyst for directly preparing dimethyl ether from synthesis gas and preparation method of dual-function catalyst

A bifunctional catalyst and catalyst technology, which is applied in the fields of dehydration of hydroxyl-containing compounds to prepare ether, chemical instruments and methods, catalysts for physical/chemical processes, etc. Guaranteed selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

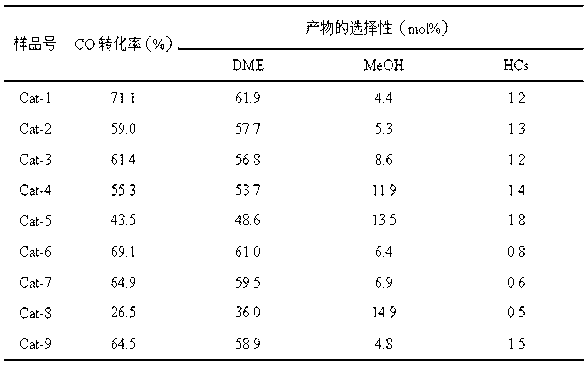

[0019] CuO-ZnO-Al was first prepared by co-current co-precipitation method 2 o 3 catalyst. The nitrate solution of copper, zinc and aluminum with a total concentration of 1mol / L (molar ratio of copper:zinc:aluminum=6:3:1) was mixed with 1mol / L Na 2 CO 3 The solution was poured into the three-necked flask concurrently under stirring, and precipitated at 80°C, pH=7.0, then aged and washed, washed with distilled water until neutral, dried in an oven at 120°C overnight, and roasted at 350°C After 5 hours, a methanol synthesis catalyst was prepared, and the methanol synthesis catalyst was pressed into pellets with a diameter of 20-40 meshes for use.

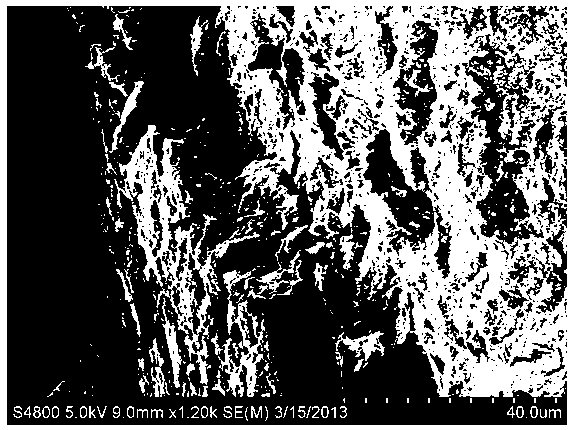

[0020] Dissolve 2.0g of aluminum nitrate in 80mL of deionized water, then add 0.4mL of ethyl orthosilicate, stir until completely dissolved, add 2.0g of methanol synthesis catalyst particles into the aqueous solution of ethyl orthosilicate and aluminum nitrate, transfer to In a stainless steel reaction kettle, react at 120°C for 6...

Embodiment approach 2

[0024] Methanol Synthesis Catalyst CuO-ZnO-Al 2 o3 The synthetic method is the same as embodiment 1.

[0025] Dissolve 2.0g of aluminum nitrate in 80mL of deionized water, then add 0.1mL of ethyl orthosilicate, stir until completely dissolved, add 2.0g of methanol synthesis catalyst particles into the aqueous solution of ethyl orthosilicate and aluminum nitrate, transfer to In a stainless steel reaction kettle, react at 120°C for 12 hours under rotating conditions, and the obtained product is filtered, washed, and dried to obtain a bifunctional catalyst Cat-2 for directly preparing dimethyl ether from synthesis gas.

[0026] Bifunctional Catalyst-2 Surface SiO Catalyst for Direct Preparation of DME from Syngas 2 -Al 2 o 3 The shell thickness is 8 μm.

[0027] Catalyst evaluation conditions are the same as in Example 1, and the catalytic results obtained are shown in Table 1.

Embodiment approach 3

[0029] Methanol Synthesis Catalyst CuO-ZnO-Al 2 o 3 The synthetic method is the same as embodiment 1.

[0030] Dissolve 2.0g of aluminum nitrate in 80mL of deionized water, then add 0.2mL of ethyl orthosilicate, stir until completely dissolved, add 2.0g of methanol synthesis catalyst particles into the aqueous solution of ethyl orthosilicate and aluminum nitrate, transfer to In a stainless steel reaction kettle, react at 80°C for 24 hours under rotating conditions, and the obtained product is filtered, washed, and dried to obtain a bifunctional catalyst Cat-3 for directly preparing dimethyl ether from synthesis gas.

[0031] Bifunctional Catalyst-3 Surface SiO Catalyst for Direct Preparation of Dimethyl Ether from Syngas 2 -Al 2 o 3 The shell thickness is 11 μm.

[0032] Catalyst evaluation conditions are the same as Embodiment 1, and the catalytic results obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com