a welding method

A welding method and welding liquid technology, which are applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex process, more scum generation, and no environmental protection, and achieve a simple process, less scum, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

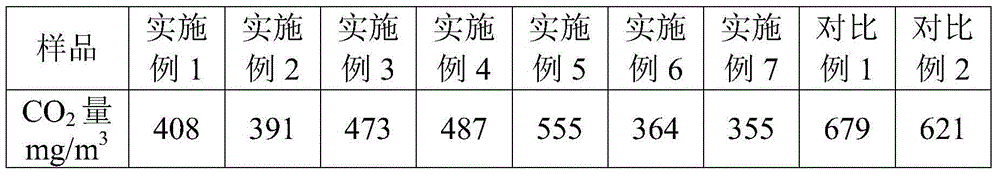

Examples

Embodiment 1

[0067] This embodiment is used to illustrate the welding method disclosed in the present invention.

[0068] Add 27 parts by weight of phytic acid and 35 parts by weight of nonylphenol polyoxyethylene ether to 3 parts by weight of ammonium metaphosphate at 90°C, and then stir at 70°C for 30 minutes. Add 35 parts by weight of nonylphenol polyoxyethylene ether and stir for 30 minutes. A reducing agent composition S1 is obtained.

[0069] In the solder pool of the wave soldering machine, melt tin-silver-copper alloy solder (96.5% Sn, 3% Ag, 0.5% Cu) at 275°C, and then add reducing agent composition S1 to form a solder with the above composition on the surface of the molten solder The reduced layer, began to wave solder the printed circuit board.

Embodiment 2

[0071] This embodiment is used to illustrate the welding method disclosed in the present invention.

[0072] Add 3 parts by weight of ammonium dihydrogen phosphate to 3 parts by weight of ammonium metaphosphate at 90°C, then add 24 parts by weight of phytic acid and 50 parts by weight of nonylphenol polyoxyethylene ether, and then stir at 70°C for 40 minutes. Add 20 parts by weight of nonylphenol polyoxyethylene ether and stir for 40 minutes. A reducing agent composition S2 is obtained.

[0073] In the solder pool of the wave soldering machine, melt tin-silver-copper alloy solder (96.5% Sn, 3% Ag, 0.5% Cu) at 275°C, and then add reducing agent composition S2 to form on the surface of the molten solder. The reduced layer, began to wave solder the printed circuit board.

Embodiment 3

[0075] This embodiment is used to illustrate the welding method disclosed in the present invention.

[0076] Add 15 parts by weight of citric acid and 50 parts by weight of nonylphenol polyoxyethylene ether to 5 parts by weight of ammonium metaphosphate at 100°C, and then stir at 90°C for 10 min. Add 30 parts by weight of nonylphenol polyoxyethylene ether and stir for 15 minutes. A reducing agent composition S3 is obtained.

[0077] In the solder pool of the wave soldering machine, melt the tin-silver-copper alloy solder (96.5% Sn, 3% Ag, 0.5% Cu) at 275°C, and then add the reducing agent composition S3 to form the above-mentioned composition on the surface of the molten solder The reduced layer, began to wave solder the printed circuit board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com