Automatic compensating machining method of medical bracket pipe diameter tolerance

A technology of automatic compensation and processing methods, applied in metal processing equipment, manufacturing tools, optical devices, etc., can solve problems such as low pass rate, improve the success rate, avoid excessive waste, and improve dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for automatically compensating the diameter tolerance of a medical bracket, the processing equipment used includes a bracket laser cutting machine, a through-beam measuring head and a control system processing center, and the through-beam measuring head is installed on the tube on the two-dimensional motion platform in the bracket laser cutting machine Between the chuck and the clamping bushing near the cutting area of the pipe; the automatic compensation processing method includes the following steps:

[0039] a) The bracket pipe is clamped on the chuck of the laser cutting machine, the chuck is fixed on the rotation axis of the laser cutting machine, and the bracket pipe is between the signal generator and the signal receiver of the beam measuring head;

[0040] b) When the pipe is in the cutting state, the linear axis will drive the rotating axis to move to the right, and the through-beam measuring head will detect the actual pipe diameter of each point in ...

Embodiment 2

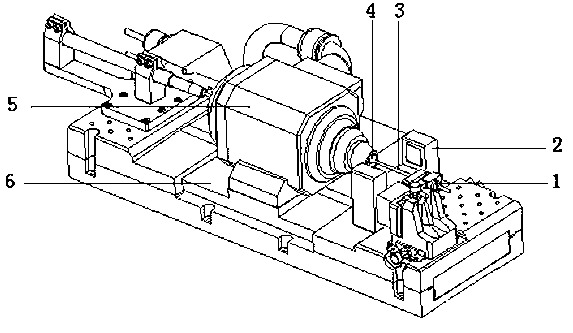

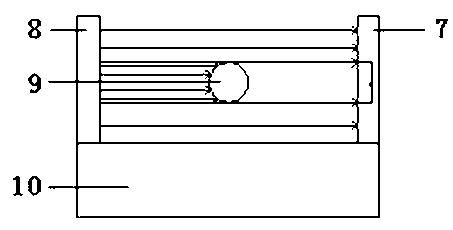

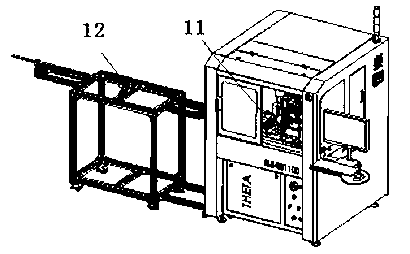

[0044] A processing method for automatically compensating the diameter tolerance of a medical stent, the method adopts the through-beam measuring head ( figure 2 2) Mounted on the bracket laser cutting machine ( Figure 4 Shown) Inner two-dimensional motion platform ( figure 2 5 and 6) on the pipe clamp ( figure 2 middle 4) and the clamping bushing near the cutting area of the pipe ( figure 2 1) between, just to allow the bracket tubing ( figure 2 3) The signal generator in the through-beam measuring head ( image 3 8) and the signal receiver ( image 3 7), the bracket tubing is first placed directly on the feed support module ( Figure 4 12) and pass through the rotation axis on the two-dimensional motion platform ( figure 2 Middle 5), the middle passes through the pipe chuck ( figure 2 Middle 4) until the pipe bushing ( figure 2 Middle 1) The cutting head at the right end is in the cutting area below. Due to the bracket tubing ( figure 2 Middle 3) First ...

Embodiment 3

[0049] A processing method for automatically compensating the diameter tolerance of a medical stent. The processing equipment for automatically compensating for the caliber tolerance of the medical stent used in the method includes a stent laser cutting machine, a through-beam measuring head and a control system processing center. The through-beam measuring head is installed on the support Between the pipe chuck on the two-dimensional motion platform in the laser cutting machine and the clamping bushing near the cutting area of the pipe; when the pipe is in the cutting state, the bracket pipe is clamped on the chuck, and the chuck is fixed on the rotating shaft On the top, the bracket pipe is between the signal generator and the signal receiver of the beam probe; the linear axis will drive the rotation axis to move to the right, and the beam probe will detect the actual pipe diameter of each point in real time, and the measured actual pipe diameter data It is transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com