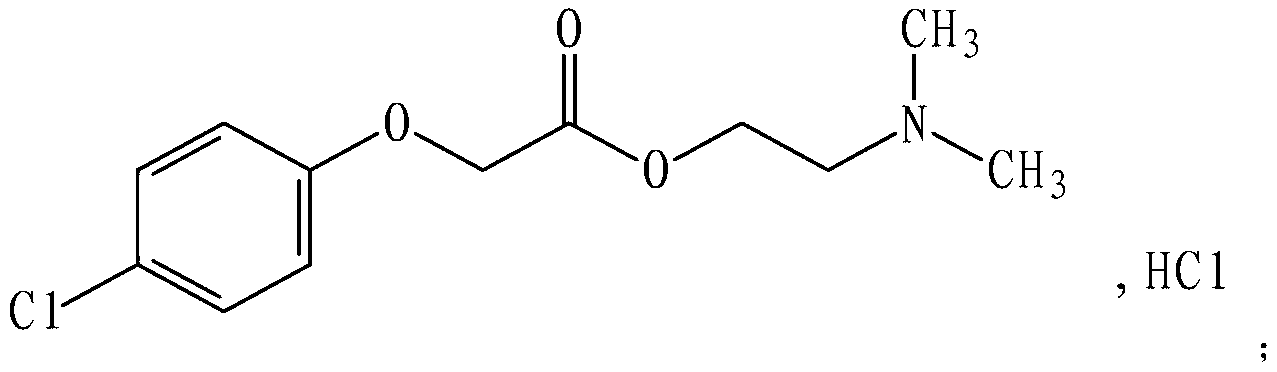

Meclofenoxate hydrochloride compound and pharmaceutical composition thereof

A technology for meclofen axetil hydrochloride and a compound, applied in the field of medicine, can solve the problems of reducing the content of the active ingredient meclofen axetil hydrochloride, increasing the medication risk of patients, increasing the content of impurities, etc., so as to improve storage stability and improve medication safety. , the effect of less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of meclofenoxate hydrochloride compound:

[0043]Dissolve the meclofenoxate hydrochloride crude drug 50 in 150ml of n-butanol, place it in a 60°C water bath, stir for 30 minutes, slowly add acetone dropwise, and the stirring rate during the dropwise addition of acetone is 27rpm, the acetone and n-butanol The volume ratio of the solution is 1:5, continue to stir for 20 minutes after the dropwise addition, add activated carbon, the amount of activated carbon is 0.2% g / ml of the total volume of the liquid, stir for 20 minutes, filter, stand for more than 24 hours, volatilize the solvent and grow crystals , cooled to 0°C, filtered to obtain a filter cake, washed the filter cake, and then dried under reduced pressure for 4 hours to obtain a white microcrystalline powder. Yield 71.2%, HPLC content 99.85%. mp: 182-185°C.

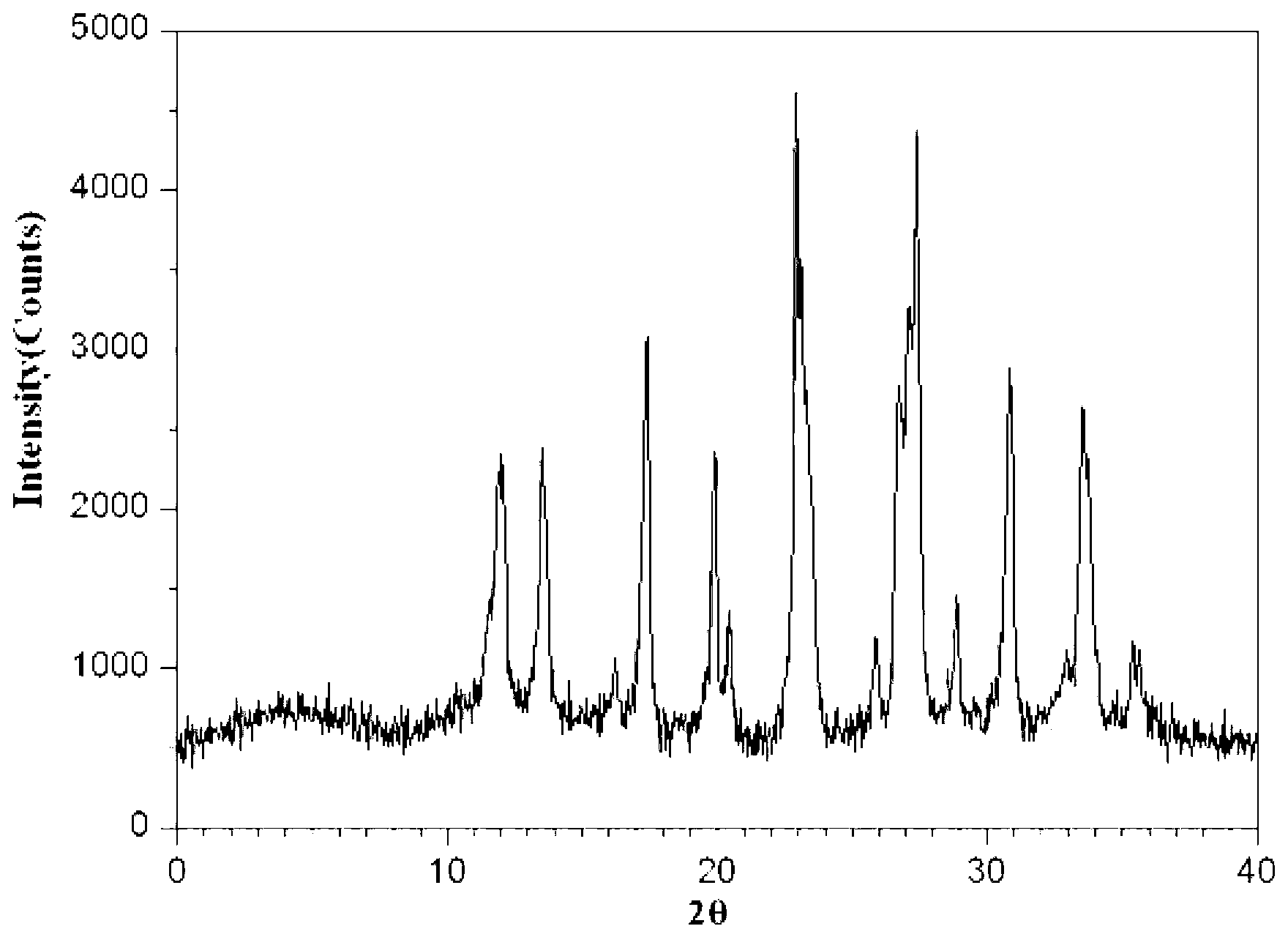

[0044] The X-ray powder diffraction spectrum obtained by Cu-Kα ray measurement is figure 1 displayed.

Embodiment 2

[0046] The preparation of meclofenoxate hydrochloride compound:

[0047] Dissolve the meclofenoxate hydrochloride crude drug 50 in 250ml of n-butanol, place it in a water bath at 50°C to insulate, stir for 20 minutes, slowly add acetone dropwise, and the stirring rate during the dropwise addition of acetone is 28rpm, the acetone and n-butanol The volume ratio of the solution is 1:8. After the dropwise addition, continue to stir for 30 minutes, add activated carbon, the amount of activated carbon is 0.3% g / ml of the total volume of the liquid, stir for 20 minutes, filter, stand for more than 24 hours, volatilize the solvent and grow crystals , cooled to 5°C, filtered to obtain a filter cake, washed the filter cake, and then dried under reduced pressure for 2 hours to obtain a white microcrystalline powder. Yield 70.9%, HPLC content 99.88%. mp: 182-185°C.

[0048] The X-ray powder diffraction pattern obtained by Cu-Kα ray measurement is consistent with the result of Example 1....

Embodiment 3

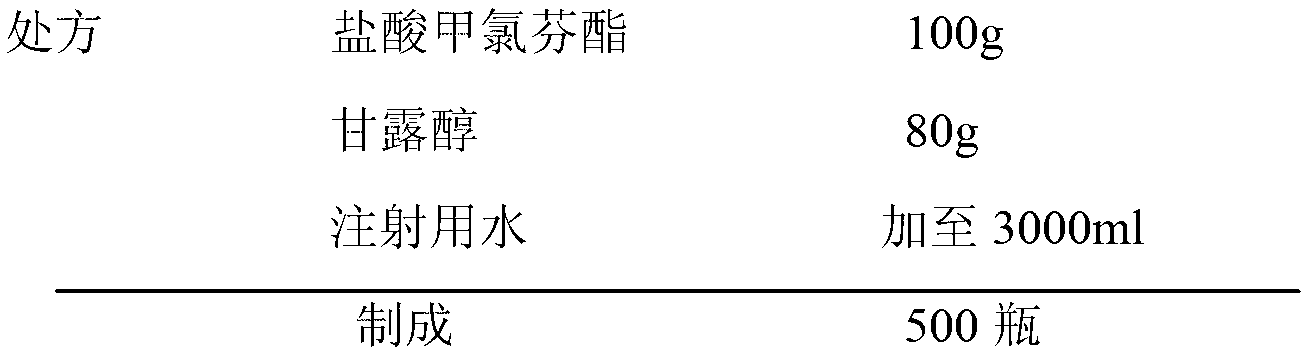

[0050] Meclofenoxate hydrochloride sterile powder injection

[0051] Weigh 998 g of meclofenoxate hydrochloride and 2 g of sodium benzoate prepared in Example 1 under aseptic conditions, place them in a solid powder mixer and mix them evenly, and the raw materials obtained are transferred to a sterile preparation workshop for precise metering and subpackaging. Each bottle contains Meclofenoxate hydrochloride 0.25g, stoppered and capped, the finished product is packaged for storage and sent for inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com