Process for improving arsenic gold concentrate roasting arsenic and sulfur removal rate

A technology for gold concentrate and desulfurization rate, applied in the fields of metallurgy, chemical industry, and gold smelting, can solve the problems of waste of resources, low gold recovery rate, poor arsenic roasting removal effect, etc. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

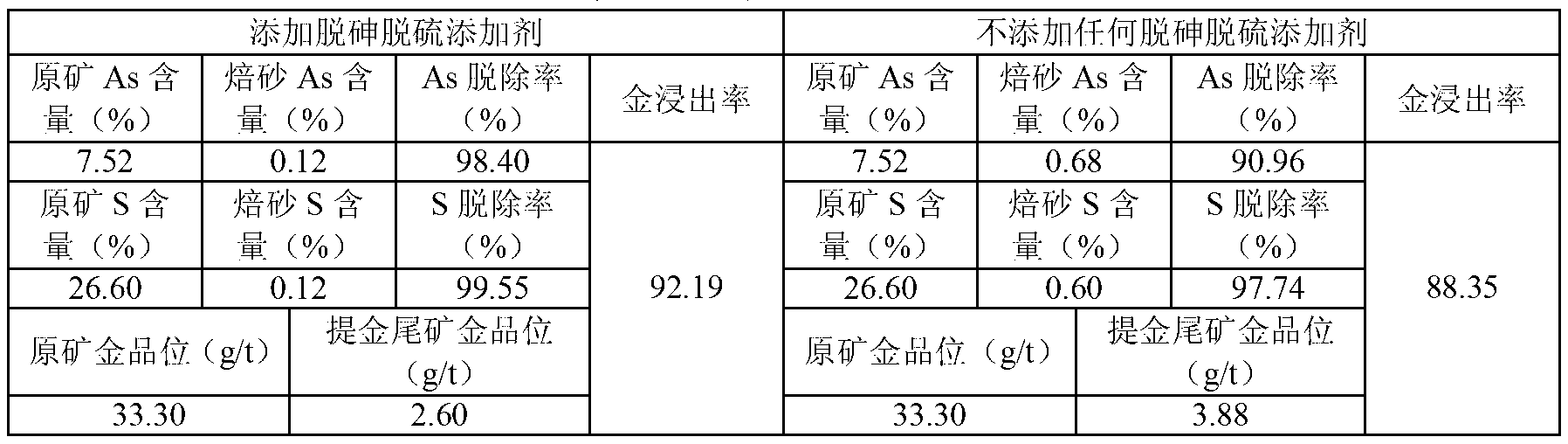

[0017] Example 1 does not add any arsenic and desulfurization additives

[0018] 1) Blend the arsenic-containing gold concentrate in the slurry mixing tank: according to the detection fineness and analysis content of the incoming arsenic-containing gold concentrate, organize the stockyard blending, shovel it into the silo of the feeding plant, and then the production workshop Organize the slurry so that the slurry contains 25% of the total mass of sulfur and 6% of arsenic, and add water to adjust the concentration of the slurry to 65%;

[0019] 2) Spray the evenly stirred ore slurry in step 1) into the primary roasting furnace with a spray gun, and carry out reduction roasting. The temperature is controlled at 550°C. The discharged roasting flue gas enters the primary cooling dust collector. Enter the secondary roasting furnace for oxidation roasting, the temperature is controlled at 630 ° C, the dusty flue gas discharged from the oxidation roasting enters the secondary coolin...

Embodiment 2

[0022] Example 2 Addition of arsenic and desulfurization additives

[0023] 1) Blend the arsenic-containing gold concentrate in the slurry mixing tank: according to the detection fineness and analysis content of the incoming arsenic-containing gold concentrate, organize the stockyard blending, shovel it into the silo of the feeding plant, and then the production workshop Tissue pulping, so that the pulp contains 25% of sulfur and 6% of arsenic in the total mass of the pulp, add water and 3% of the total mass of the pulp additives (mass ratio 1:1:1:3 ammonium sulfate, ammonium bicarbonate, Ammonium carbonate, sodium persulfate mixture), adjust the slurry concentration to 65%;

[0024] 2) Spray the evenly stirred ore slurry in step 1) into the primary roasting furnace with a spray gun, and carry out reduction roasting. The temperature is controlled at 550°C. The discharged roasting flue gas enters the primary cooling dust collector. Enter the secondary roasting furnace for oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com