Trench gate type insulated gate bipolar translator (IGBT) with double-face diffusion residual layer and manufacturing method thereof

A technology of diffusion residual layer and double-sided diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

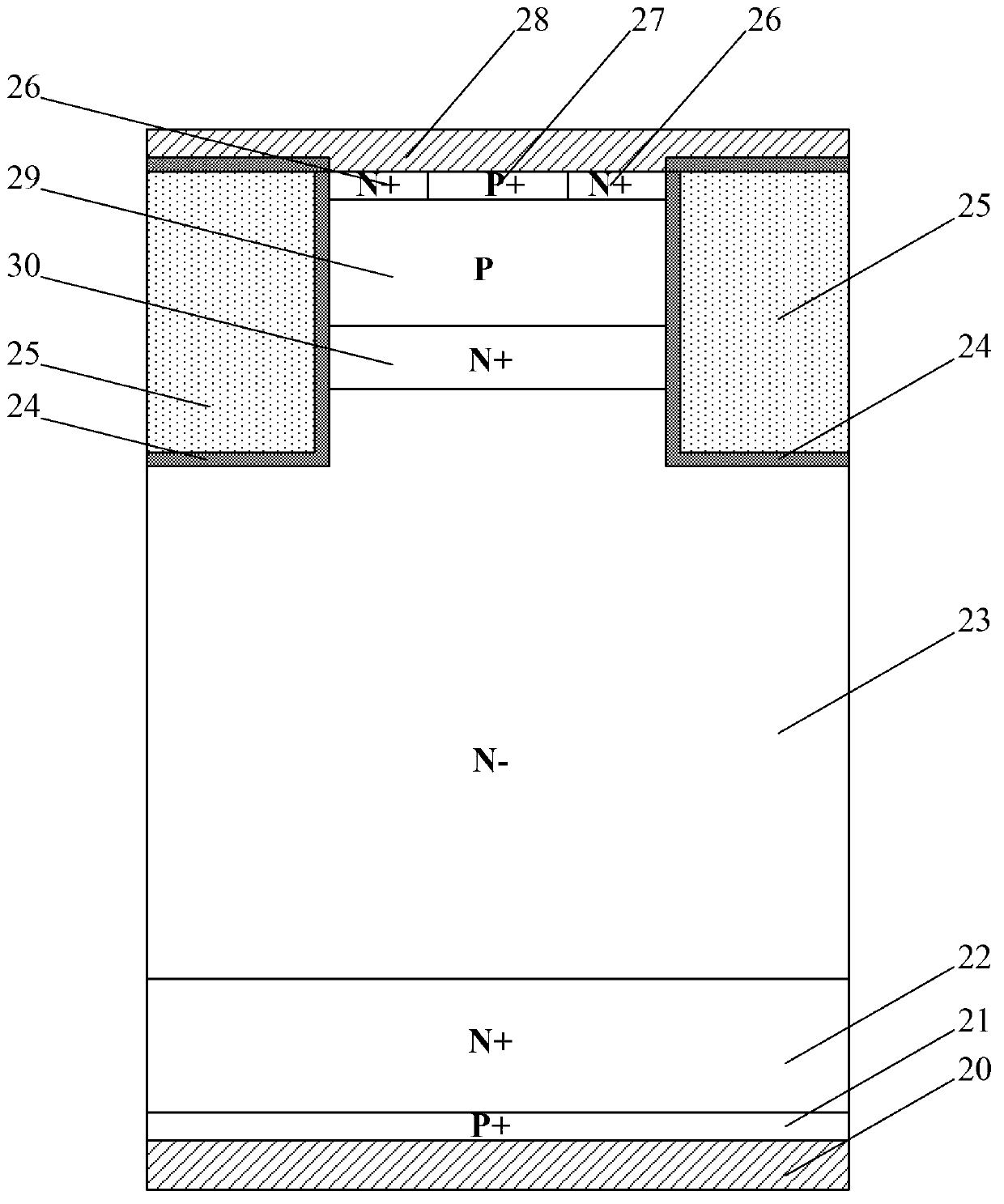

[0032] like figure 1 As shown, a trench gate type IGBT with a double-sided diffused residual layer includes an N-type base region, a P-type base region 29, a back P+ collector region 21, an N+ emitter region 26, a P+ emitter region 27, Gate oxide layer 24, emitter 28, gate electrode 25 and collector 20, wherein the N-type base region is composed of N+ diffusion residual layer 30, N-drift region 23 and N+ buffer layer 22 in sequence. The IGBT manufacturing process is shown in Figure 2 As shown, the details are as follows:

[0033] like Figure 2a The shown N-type single crystal substrate 31 with a crystal orientation of has a doping concentration of 4.3×10 13 cm -3 , the thickness is 500um, according to the needs of the forward blocking voltage (such as 1700V, the same below), the doping concentration can be adjusted to 1×10 13 ~2×10 14 cm -3 .

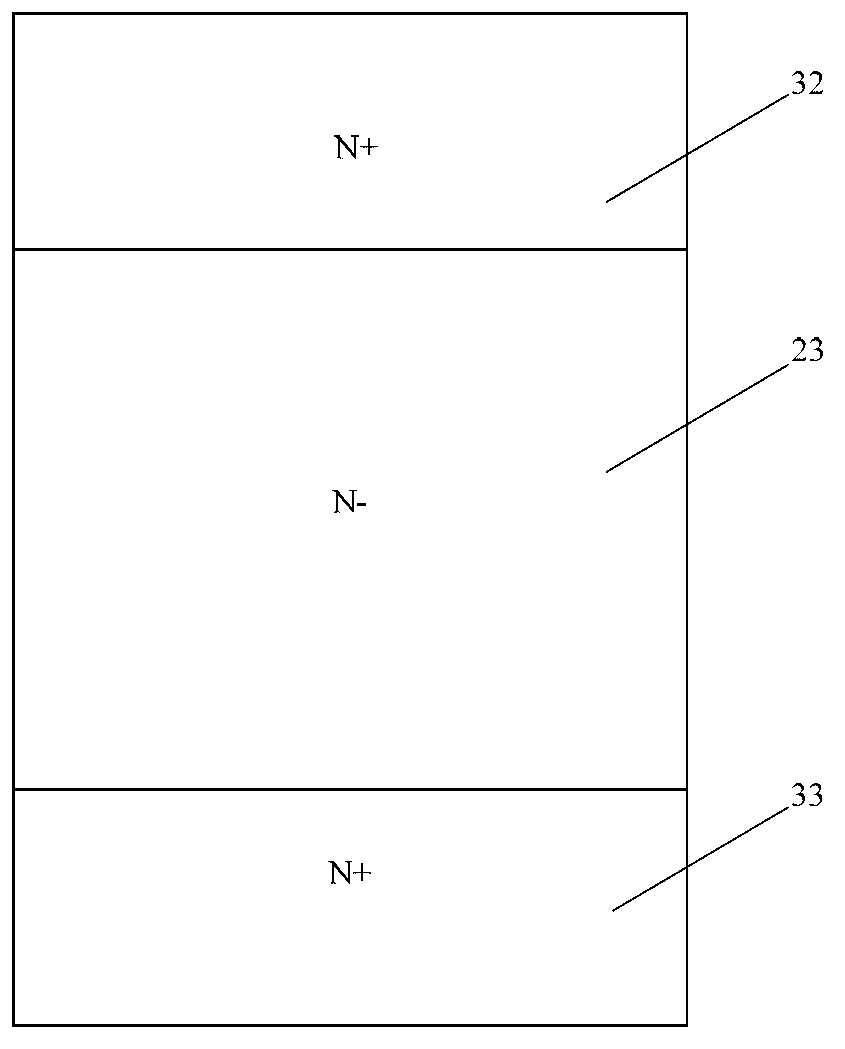

[0034] like Figure 2b As shown, the N-type single crystal substrate undergoes a double-sided high-temperature deep junction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com