Rapid starting method of membrane bioreactor completely-autotrophic nitrogen removal technology

A full-process autotrophic denitrification, membrane bioreactor technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of low total nitrogen removal load, difficulty in starting the reactor, and slow growth. and other problems, to achieve the effect of solving slow growth, simple and easy-to-obtain sludge, and solving difficult sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

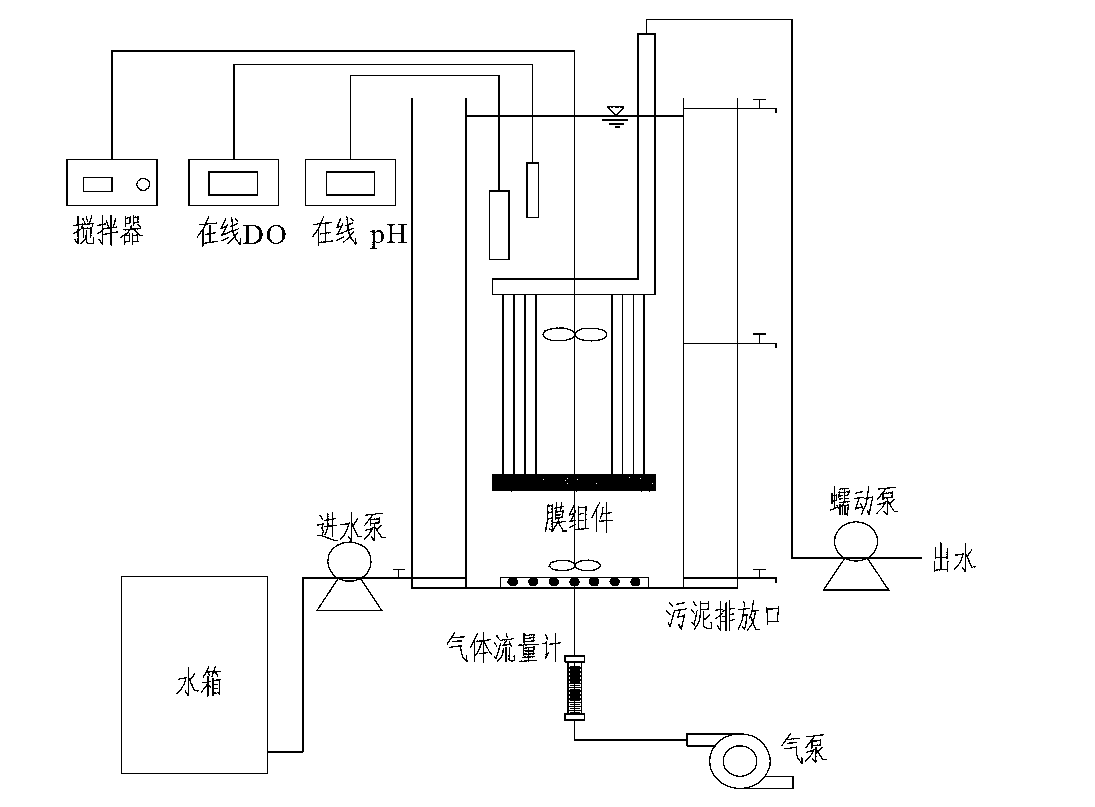

[0016] The reactor used in the present invention is a membrane bioreactor (MBR), and the effective volume of the reactor is 13L. An aeration device is installed at the bottom of the reactor, and the DO concentration in the reactor wastewater can be controlled by adjusting the aeration amount. The built-in agitator ensures that the mud and water are mixed evenly. The inlet pump is connected to the liquid level controller to keep the liquid level constant. The outlet water is sucked out by the peristaltic pump. The test uses artificially synthesized wastewater as the test water, and the influent matrix mainly includes 0.33~0.94g / L (NH 4 ) 2 SO 4 , 0.94~3.36g / L NaHCO 3 , while adding 0.068g / L of CaCl 2 , 0.15g / L of MgSO 4 ·H 2 O, 0.068g / L of KH 2 PO 4 .

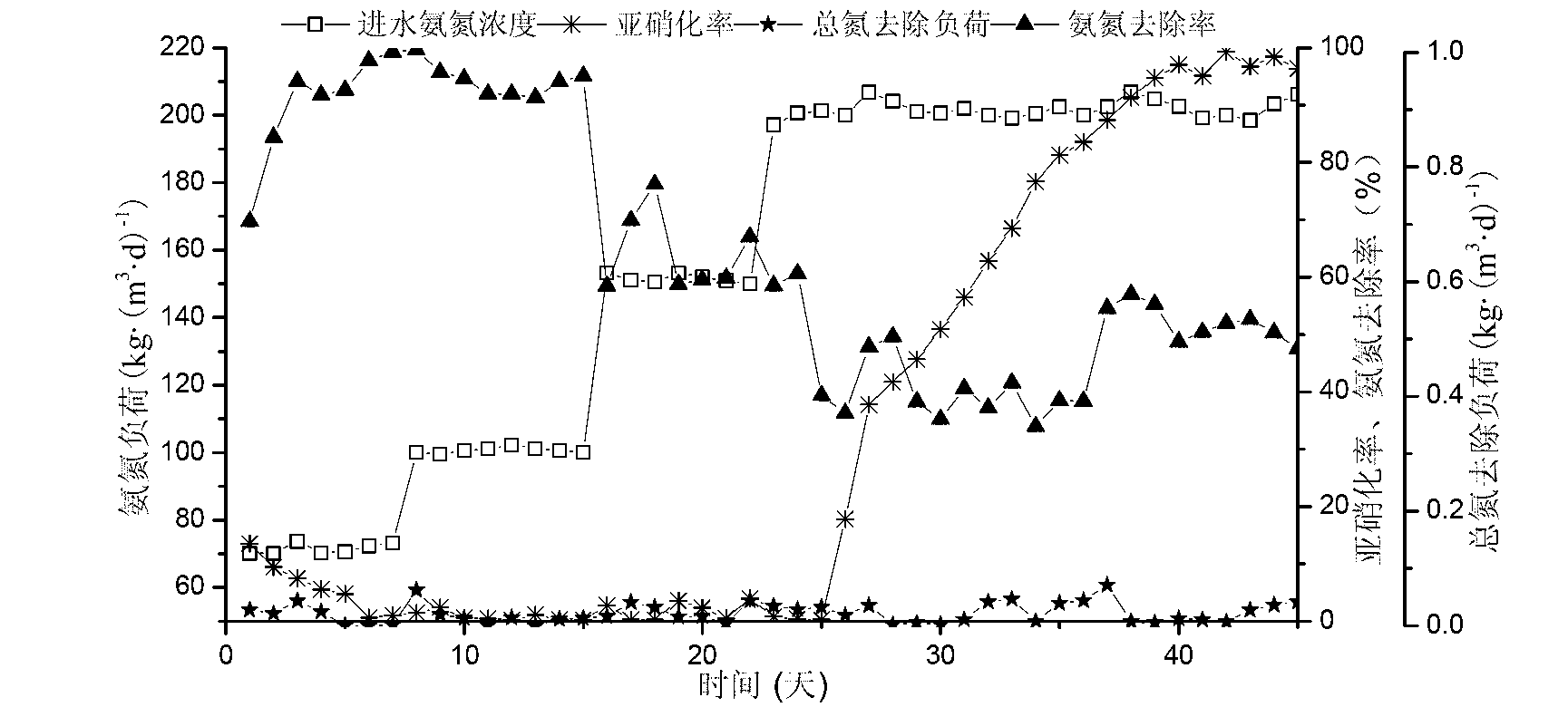

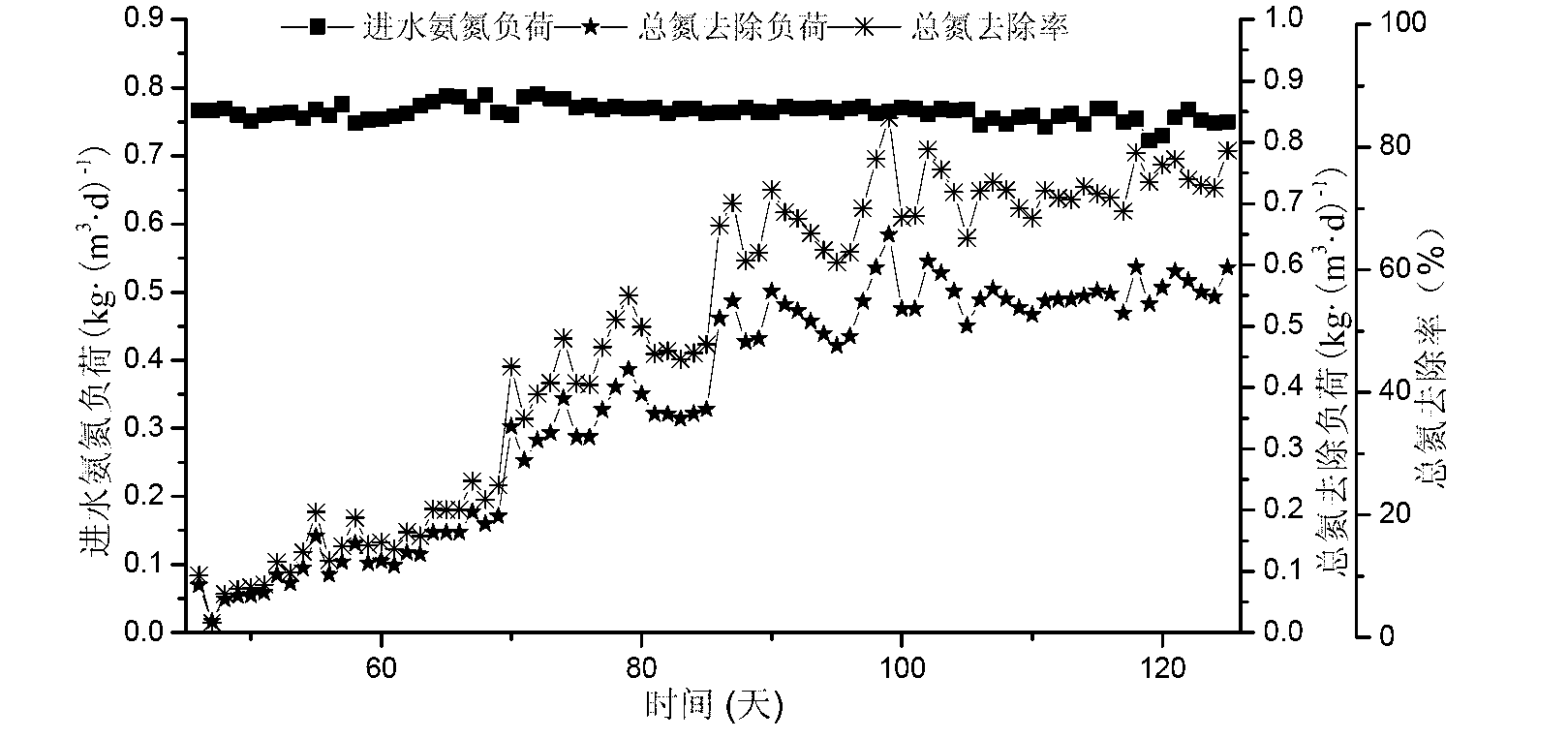

[0017] In the present invention, the method for quickly starting the whole process of autotrophic denitrification process is as follows: in the MBR reactor, inoculate with A 2 Nitrified sludge from urban sewage treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com