Biological organic fertilizer and production method thereof

A bio-organic fertilizer and production method technology, applied in the field of bio-organic fertilizer production, can solve problems such as high cost of raw materials, damage to soil structure, and limited use range, and achieve the effect of improving physical and chemical properties, improving soil structure, and a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

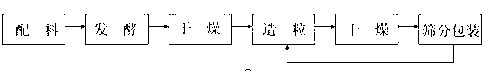

Image

Examples

Embodiment 1

[0018] Embodiment 1: A kind of bio-organic fertilizer, described bio-organic fertilizer is made of the raw material of following percentage by weight: Sheep manure: 60%, soybean meal: 10%, biologically active strain: 0.05%, weathered coal: 29.95% .

[0019] The production method comprises the steps of:

[0020] Step 1: Mix sheep manure: 60%, soybean meal: 10%, biologically active strains: 0.05%, and weathered coal: 29.95% in proportion, and stir evenly;

[0021] Step 2: Transfer the mixed material to the fermentation tank for fermentation, the fermentation temperature is 60°C, the fermentation time is 18 days, and the material is stirred every two days during the fermentation process;

[0022] Step 3: Dry the fermented material at a high temperature of 70°C;

[0023] Step 4: Put the dried material into the granulation equipment after being pulverized by a pulverizer, and add deionized water for granulation treatment;

[0024] The fifth step: drying, the manufactured fertili...

Embodiment 2

[0026] Embodiment 2: A kind of bio-organic fertilizer, described bio-organic fertilizer is made of the following raw materials by weight percentage: Cow dung: 50%, cottonseed cake: 20%, biologically active strain: 0.1%, weathered coal: 29.9% %.

[0027] The production method comprises the steps of:

[0028] Step 1: Mix cow manure: 50%, cottonseed cake: 20%, biologically active bacteria: 0.1%, and weathered coal: 29.9% in proportion, and stir evenly;

[0029] Step 2: Transfer the mixed material to the fermentation tank for fermentation treatment, the fermentation temperature is 80°C, the fermentation time is 15 days, and the material is stirred every two days during the fermentation process;

[0030] Step 3: Dry the fermented material at a high temperature of 50°C;

[0031] Step 4: Put the dried material into the granulation equipment after being pulverized by a pulverizer, and add deionized water for granulation treatment;

[0032] The fifth step: drying, the manufactured f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com