Photovoltaic power generation component junction box

A photovoltaic power generation and junction box technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of strengthening the thermal interference of bypass diodes in solar junction boxes, permanent failure of devices, and unreasonable packaging forms, etc., to reduce Heat transfer interference effect, good electrical insulation performance, effect of reducing heat interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

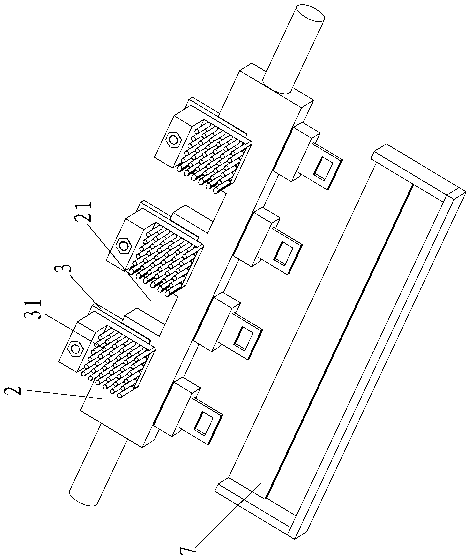

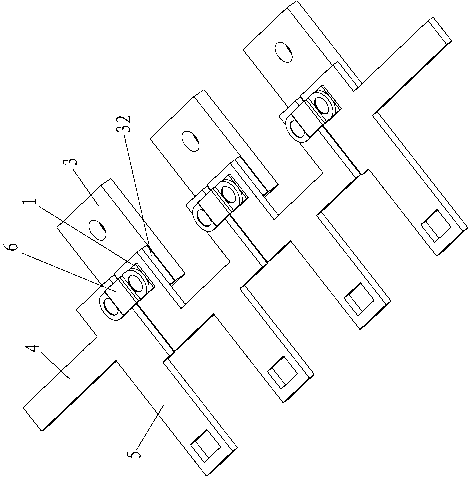

[0039] Embodiment 1: as Figure 1-2 As shown, a junction box for a photovoltaic power generation module includes a box body 7 on which a diode chipset and a package body 2 for packaging the diode chipset are arranged. The diode chipset has at least one bypass diode 1. In this implementation example Figure 1-2 There are three shown: the connecting terminal 4 electrically connected to the cable at both ends of the bypass circuit and the box body 7, the connecting terminal 5 of the busbar of the battery assembly electrically connected to each bypass diode 1, and the connecting terminal 5 of the busbar of adjacent battery assemblies A bypass diode chip jumper 6 is provided; the box body 7 shown in the figure is a partial diagram of the box body 7 .

[0040] A heat sink 3 for heat dissipation is provided under each bypass diode 1 , and the heat sink 3 and the bypass diode 1 are electrically insulated by a thermally conductive insulating sheet 32 , and the heat sink 3 extends to...

Embodiment 2

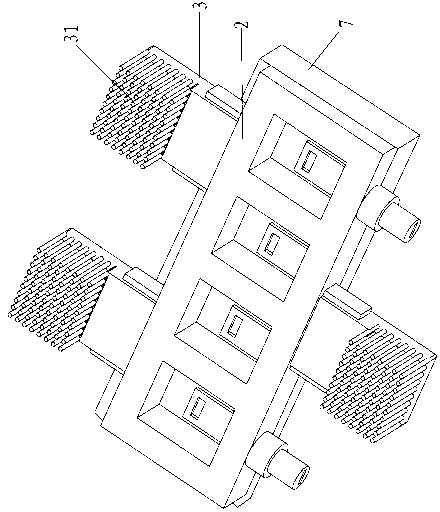

[0045] Embodiment 2: as Figure 3-4 As shown, a junction box for a photovoltaic power generation module includes a box body 7 on which a diode chipset and a package body 2 for packaging the diode chipset are arranged. The diode chipset has at least one bypass diode 1. In this implementation example Figure 4 There are three shown; the bypass diode 1 at both ends of the box body 7 is also electrically connected to the cable lead terminal 4, and each bypass diode 1 and the cable lead terminal 4 are electrically connected to the battery assembly bus connection terminal 5, and the adjacent battery assembly A bypass diode chip jumper 6 is provided between the bus strip connection terminals 5 .

[0046] The diode chipset is fully encapsulated and packaged with electrically insulating and highly thermally conductive epoxy resin, and molded together with the package body 2 at one time.

[0047] At the same time, the bypass diodes 1 are respectively arranged on both sides of the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com