Preparation method of ternary cathode material

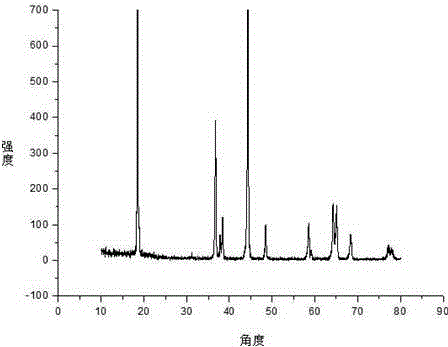

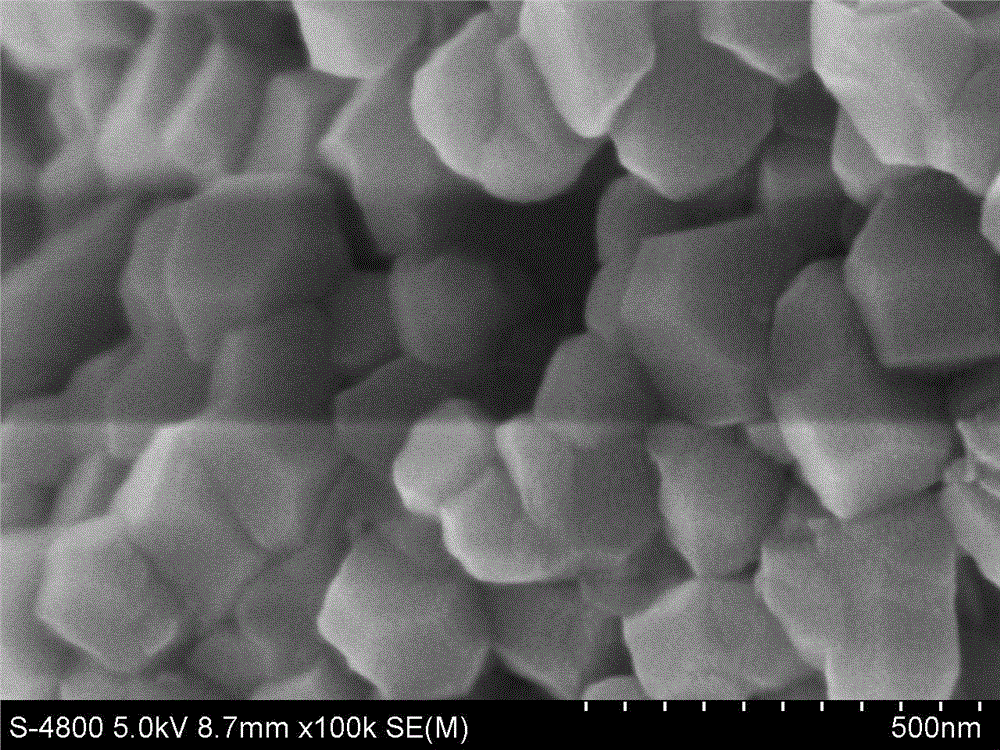

A technology of positive electrode material and crystal water, which is applied in the field of electrochemistry, can solve the problems that affect the stability of product batches and performance uniformity, and the difficulty of uniform mixing of raw materials, etc., and achieve the effects of shortening the preparation time, uniform particle size, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a battery ternary cathode material, the method comprising the following steps:

[0029] 1. Take 0.03 mol of lithium nitrate, 0.010 mol of nickel nitrate hexahydrate, 0.010 mol of manganese acetate tetrahydrate, and 0.010 mol of cobalt acetate tetrahydrate, and dissolve them in 75 mL of ethanol solution with a concentration of 99.9% by mass to obtain lithium-containing salt and manganese The homogeneous mixed solution of salt, in which the lithium ion concentration is 0.4 mol / L, at this time the color of the mixed solution is red with divalent manganese ions and cobalt ions.

[0030] 2. Fully stir the above-mentioned mixed solution, continue blowing air with a blower, add 13.5mL of concentrated ammonia water with a mass percentage concentration of 25%, and make the above-mentioned mixed solution become a dark black solution, that is, divalent manganese ions and cobalt ions are oxidized to The color after the higher valence state. The density of am...

Embodiment 2

[0036] A method for preparing a battery ternary cathode material, the method comprising the following steps:

[0037] 1. Take 0.03 mol of lithium acetate, 0.012 mol of nickel acetate, 0.012 mol of manganese acetate, and 0.006 mol of cobalt acetate, and dissolve them in 300 mL of ethanol solution with a concentration of 80% by mass to obtain a homogeneous mixed solution containing lithium salt and manganese salt , where the concentration of lithium ions is 0.1 mol / L, the color of the mixed solution is red with divalent manganese ions and cobalt ions.

[0038] 2. Fully stir the above-mentioned mixed solution, continuously blow in air with a blower, add 6.7mL of concentrated ammonia water with a mass percentage concentration of 25%, and make the above-mentioned mixed solution become a dark black solution, that is, the divalent manganese ion and the cobalt ion are oxidized to The color after the higher valence state. The density of ammonia water is calculated as 0.91g / mL, and the...

Embodiment 3

[0042] A method for preparing a battery ternary cathode material, the method comprising the following steps:

[0043]1. Get 0.3 mol lithium acetate dihydrate, 0.15 mol nickel nitrate hexahydrate, 0.09 mol manganese acetate tetrahydrate, and 0.06 mol cobalt nitrate hexahydrate and dissolve in 300 mL of methanol solution with a concentration of 95% by mass to obtain lithium-containing salt and A homogeneous mixed solution of manganese salts, in which the concentration of lithium ions is 1.0 mol / L, at this time the color of the mixed solution is red with divalent manganese ions and cobalt ions.

[0044] 2. fully stir the above-mentioned mixed solution, continue to blow air with the air blower, add the concentrated ammonia water 67mL that the mass percentage concentration concentration is 25%, make the above-mentioned mixed solution become dark black solution, promptly divalent manganese ion and cobalt ion are oxidized to relatively The color after the high valence state. The den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com