A replaceable film-coated filter element for purifying PM2.5 masks and preparation method thereof

A film-covering and mask technology is applied in the field of replaceable film-covered filter elements for purifying PM2.5 masks and their preparation, which can solve the problems of long conveying distance, small PM2.5 particle size, and few masks, etc., and achieve long service life. , saving resources, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

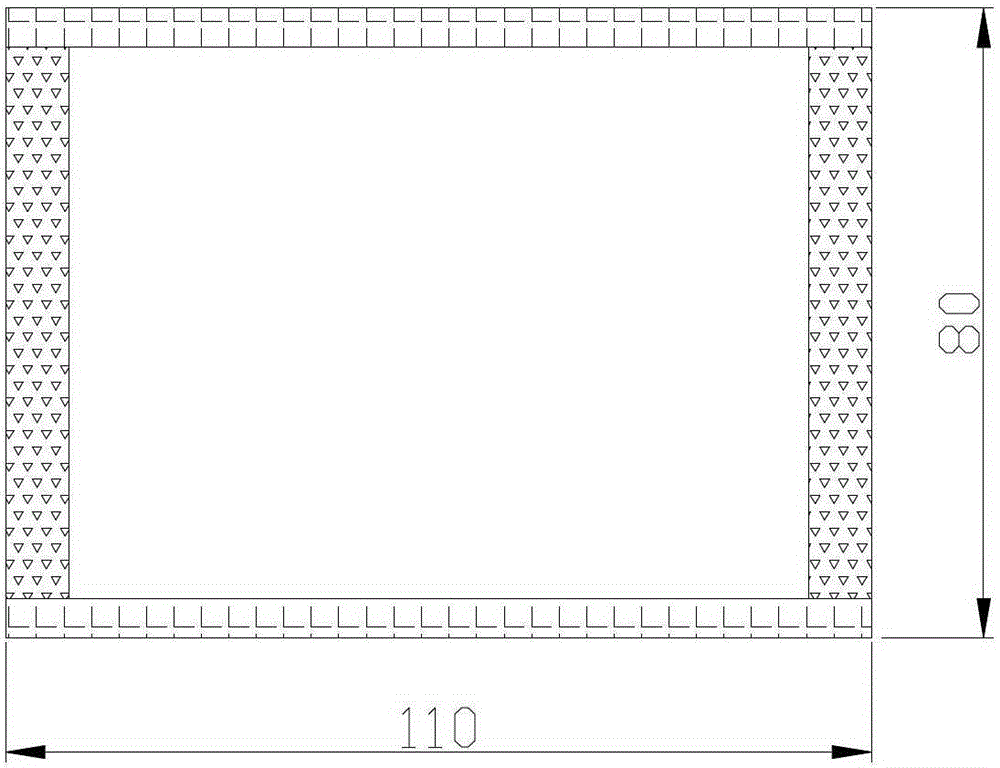

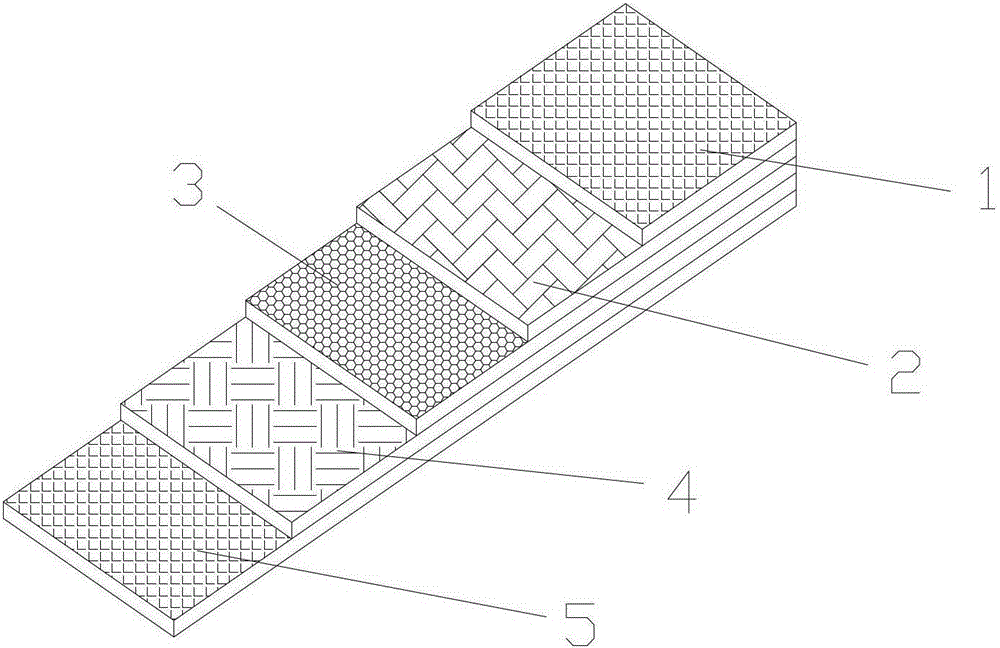

[0021] Such as figure 1 , 2 The replaceable film-coated filter element for purifying PM2.5 masks shown is composed of the first spunbonded non-woven fabric layer 1, the melt-blown non-woven fabric layer 2, the PTFE microporous membrane layer 3, and the activated carbon non-woven fabric layer from top to bottom. Layer 4 and the second spun-bonded non-woven fabric layer 5 are composited; the cross-section of the PM2.5 respirator with a replaceable film-coated filter element is rectangular, with a length of 105 cm and a width of 75 cm.

[0022] The grammage of above-mentioned first spunbond nonwoven fabric layer, melt blown nonwoven fabric layer, activated carbon nonwoven fabric layer and the second spunbond nonwoven fabric layer is 20g / m 2 ;The weight of PTFE microporous membrane is 1.0g / m 2 .

[0023] The above-mentioned PTFE microporous membrane has a pore size of 0.5 μm, a porosity of 80%, and an air permeability of 8 cm / s (127 Pa).

[0024] The above-mentioned manufactur...

Embodiment 2

[0027] Basically the same as Example 1, the difference is: the length of the PM2.5 respirator with replaceable film-covered filter element is 115cm, and the width is 85cm.

[0028] The grammage of the first spunbond nonwoven layer, melt blown nonwoven layer, activated carbon nonwoven layer and the second spunbond nonwoven layer is 30g / m 2 ;The weight of PTFE microporous membrane is 4.0g / m 2 .

[0029] The PTFE microporous membrane has a pore size of 1.0μm, a porosity of 90%, and an air permeability of 14cm / s (127Pa).

[0030] The temperature of the edge of the hot-melt seam is 160°C, and the hot-melt pressure is 0.8MPa.

[0031] The obtained replaceable film-coated filter element for purifying PM2.5 masks has a filtration efficiency of >99.97%, an air permeability of >10.0cm / s, and a filtration resistance of <150Pa. The filtration efficiency, air permeability, and filtration resistance are all tested according to GB2626-2006.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com